A test system and method for an electric wheel complete vehicle alternating current drive

A transmission test and complete vehicle technology, which is applied in the field of variable flow, can solve the problems of inability to match the performance of vehicle components, insufficient factory test, time-consuming and labor-intensive test process, etc., to achieve small footprint, simple installation and maintenance, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

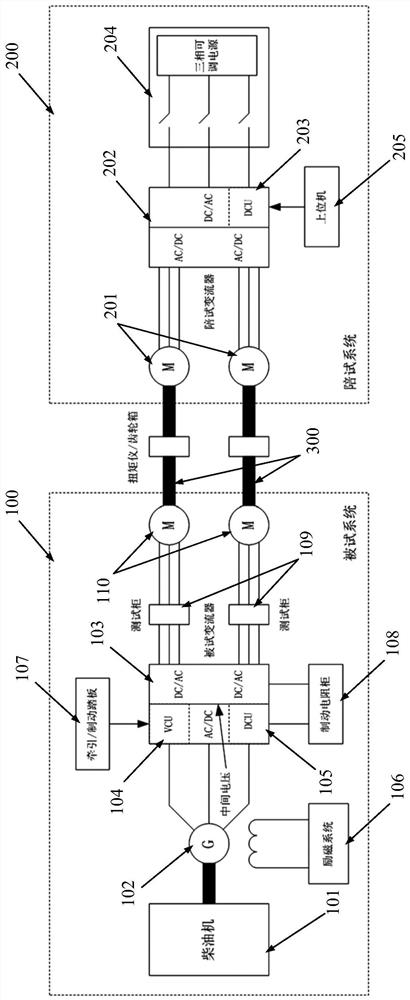

[0058] as attached figure 1 As shown, an embodiment of an electric wheel vehicle AC drive test system specifically includes:

[0059] The system under test 100 and the system under test 200.

[0060] The system under test 100 includes a diesel engine 101, a generator 102, a tested converter 103, a test cabinet 109, and a tested motor 110 connected in sequence, and a braking resistor cabinet 108 and a traction / braking system connected to the tested converter 103. Electric wheel complete vehicle unit parts including moving pedal 107. The system under test 100 is used to perform unit component performance tests including diesel engine power characteristic test, braking resistor cabinet braking capacity test, converter performance test, motor characteristic test, and including main control regulation performance, excitation regulation performance The matching performance test of multiple unit components including motor control performance.

[0061] The testing system 200 includ...

Embodiment 2

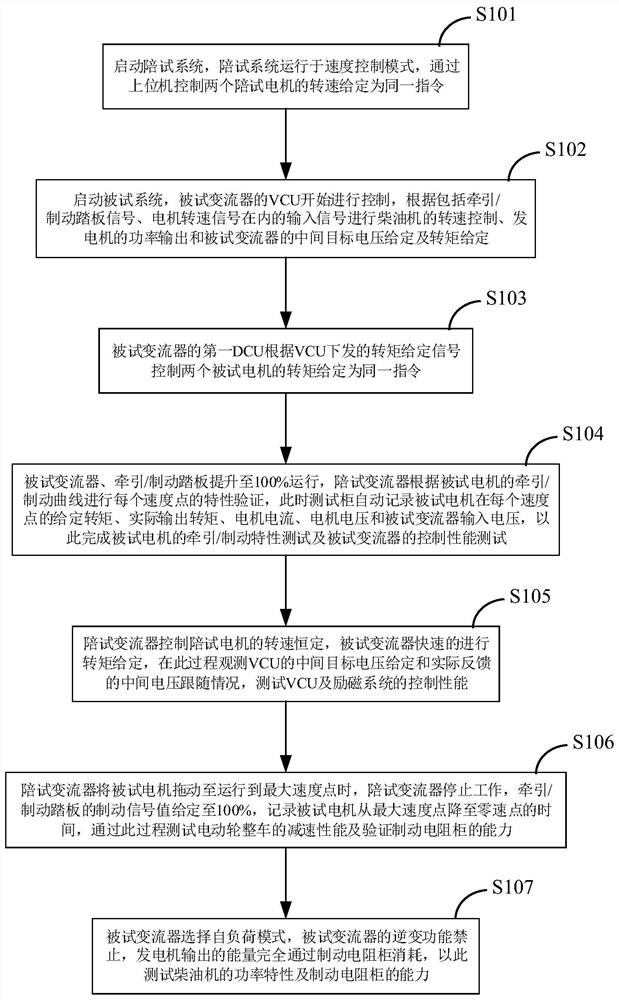

[0076] as attached figure 2 As shown, an embodiment of an electric wheel vehicle AC drive test method specifically includes the following steps:

[0077] S101) start the accompanying test system 200, the accompanying test system 200 operates in the speed control mode, and the speed of the two accompanying test motors 201 is controlled by the host computer 205 to give the same instruction; for example, after starting, control the speed of the two accompanying test motors 201 200r / min;

[0078] S102) Start the system under test 100, and the VCU 104 of the converter under test 103 starts to control, and performs the speed control of the diesel engine 101 and the power of the generator 102 according to the input signals including the traction / brake pedal signal and the motor speed signal. The intermediate target voltage of the output and tested converter 103 is given (attached figure 1 The tested converter 103 has two main functions, one is rectification (i.e. AC / DC), the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com