Degradable polymer microspheres with surface pits and preparation method and application thereof

A technology of polymer microspheres and polymer solutions, applied in the field of medicine, can solve the problems of difficult to predict the degradation rate of the internal structure of microspheres, difficult to predict performance evolution, complex preparation process, etc., to achieve good application prospects and good biocompatibility Non-toxicity and degradability, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

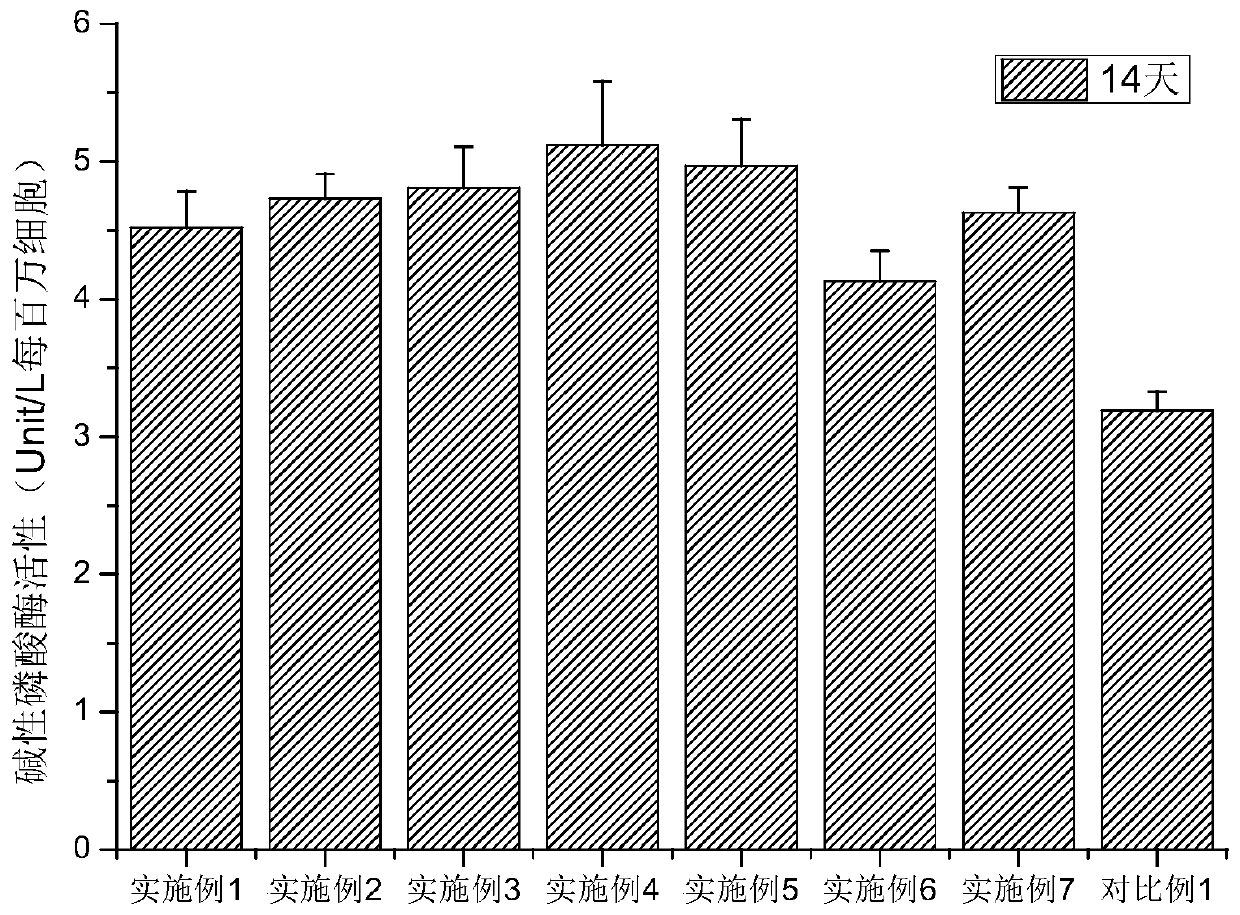

Examples

Embodiment 1

[0033] Embodiment 1 of the present invention is: a preparation method of degradable polymer microspheres with surface pits, comprising the following steps: weighing 1.5g polycaprolactone and dissolving it in 10ml volatile organic solvent (chloroform) In; the polycaprolactone solution was added to 500ml concentration of 1.2% (1788 type-polyvinyl alcohol) in the aqueous solution, stirred at room temperature using an overhead stirrer, and the rotation speed was 600rpm; 1.5g tetroxide was added after 60min Three iron particles, start the bottom type magnetic stirrer, the rotating speed is 1000rpm; wherein, the rotation direction of the top type magnetic stirrer and the bottom type magnetic stirrer are opposite. After 8h, the stirring was stopped, and a magnet was used to separate the magnetic solid particles and the microspheres embedded in the magnetic solid particles; the remaining microspheres were washed with water and centrifuged (1500rpm, 10min) and then freeze-dried (36h) to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com