Composite heat-insulation and soundproof plate

A technology of composite thermal insulation and sound insulation panels, applied in the direction of thermal insulation, sound insulation, synthetic resin layered products, etc., can solve the problems of low construction efficiency, poor comprehensive performance, complicated procedures, etc., and achieve convenient construction, safe and convenient use, and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

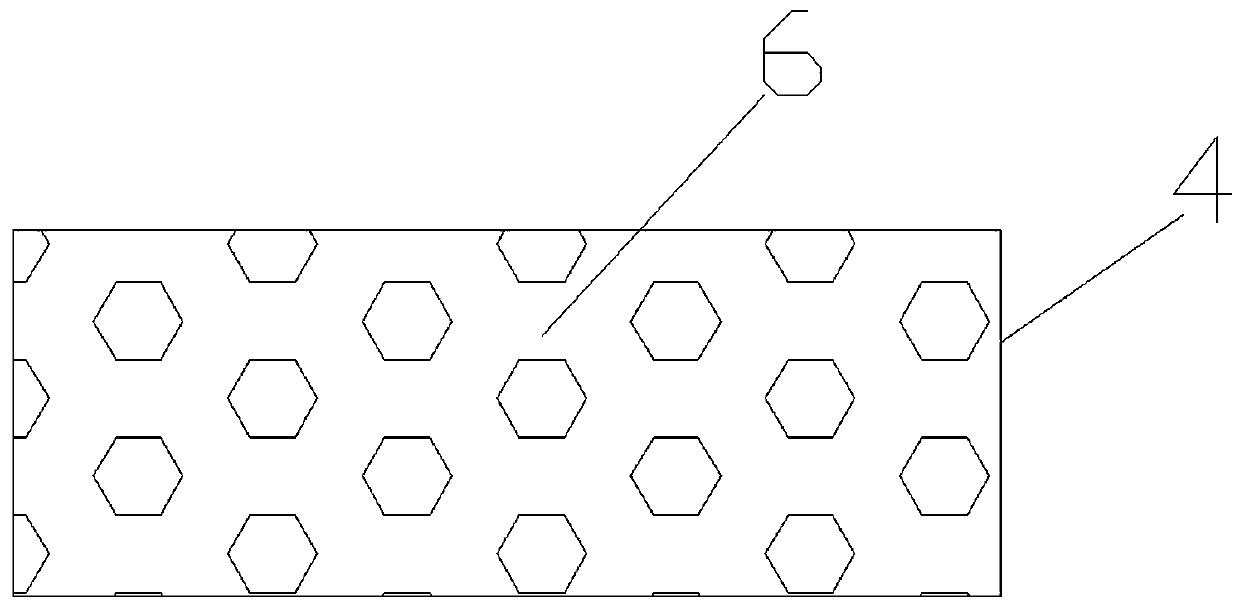

[0015] Embodiment: A composite thermal insulation and sound insulation board, including a composite thermal insulation and sound insulation board body 1; the composite thermal insulation and sound insulation board body 1 includes polyethylene polypropylene fiber layer 2, XPE layer 3, polystyrene particle board 4, non-woven Mesh cloth layer 5, polyethylene polypropylene fiber layer 2, XPE layer 3, polystyrene particle board 4, and non-woven mesh cloth layer 5 are connected sequentially from top to bottom; the XPE layer 3 is connected with polystyrene particle board 4 There are sound-absorbing concave arches 6 on the board surfaces of the polystyrene particle boards 4 .

[0016] The depth of the sound-absorbing concave arch 6 is 2.5-3.2 mm, and its shape is hexagonal, quincunx or elliptical.

[0017] The ratio of the polyethylene polypropylene fiber layer 2, the XPE layer 3, the polystyrene particle board 4, and the non-woven mesh cloth layer 5 is 4:3:6:2.

[0018] The polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com