A two-degree-of-freedom joint for deep-sea multi-joint submersible

A multi-joint, degree-of-freedom technology, used in special-purpose ships, joints, underwater operation equipment, etc., can solve the problems of small output torque of single-motor joints, inconvenient installation and maintenance, and few two-degree-of-freedom joints. Complexity, easy installation and debugging, reducing the effect of dynamic sealing links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

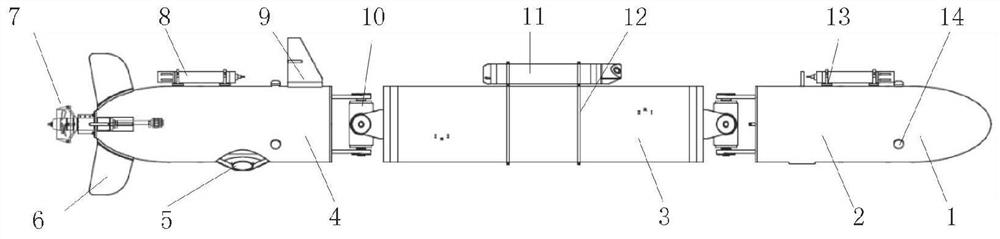

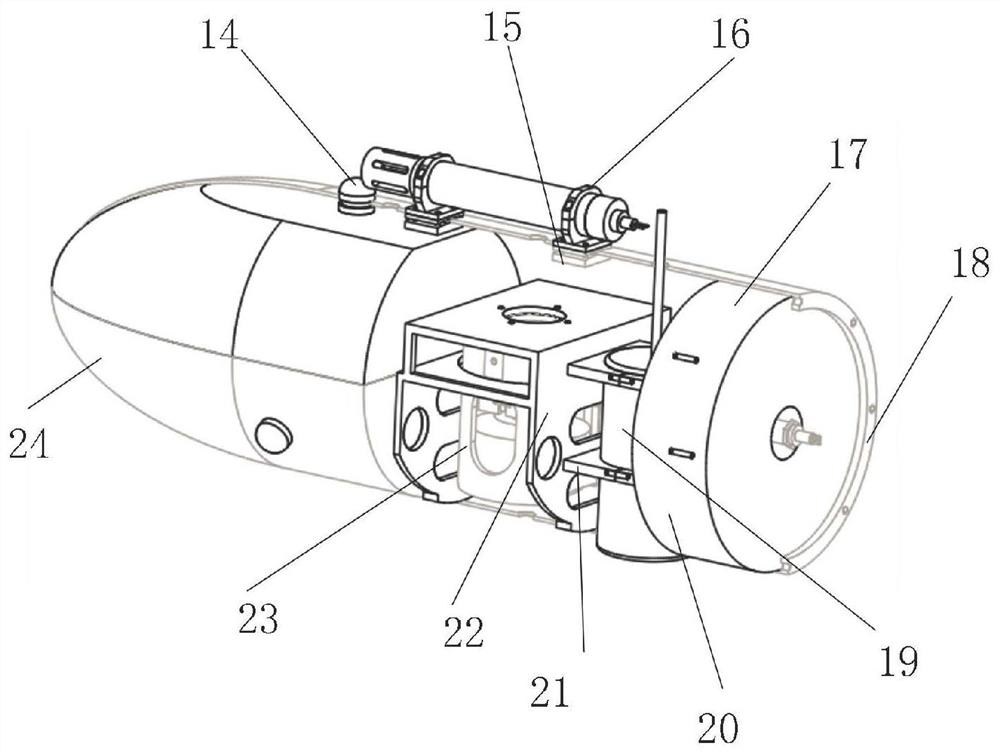

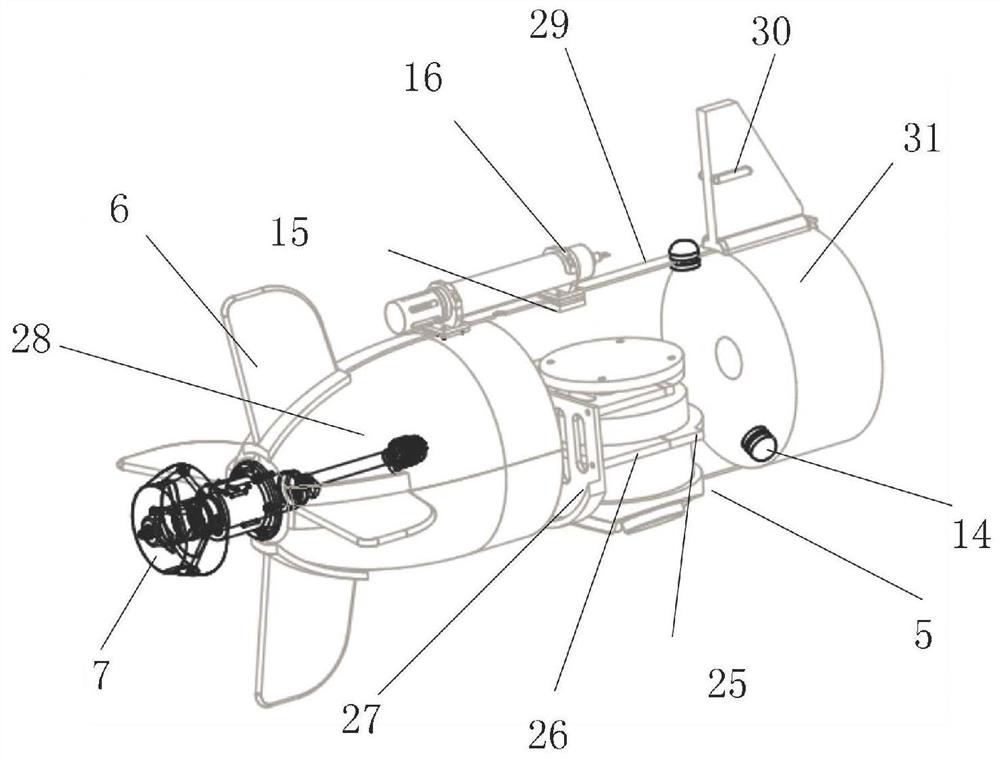

[0038] refer to Figure 1 to Figure 8 , the application scene of the joint of the present invention is a multi-joint submersible 1 for deep-sea exploration, including a diversion cabin 2, a control cabin 3, a propulsion cabin 4, a two-degree-of-freedom joint 10, a propeller 7, a tail rudder 6, and an instrument rack A 13. Instrument rack B12, antenna 9, which can be equipped with temperature, salinity and depth meter 8, Doppler log meter 5, single-point current velocity meter 11, hydrophone 14 and other instruments. The front and rear parts of the control cabin 3 are screwed to the two-degree-of-freedom joint 10 . The diversion cabin 2 and the propulsion cabin 4 are respectively connected with the two-degree-of-freedom joints 10 at the front and rear of the control cabin. Propeller 7 is installed in propelling cabin 4 afterbody. Four tail rudders 6 are evenly distributed in the rear portion of the propulsion cabin 4 around the axis. Three hydrophones 14 are evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com