High-accuracy load control device for support axial force, and use method thereof

A high-precision, shaft-supporting technology, used in hoisting devices and other directions, can solve the problems of insufficient frequency response frequency of variable frequency motors, difficult to deal with frequent starting and stopping of the system, poor accuracy, etc., to achieve suitable for frequent starting and stopping, effective and accurate horizontal displacement, The effect of unloading precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

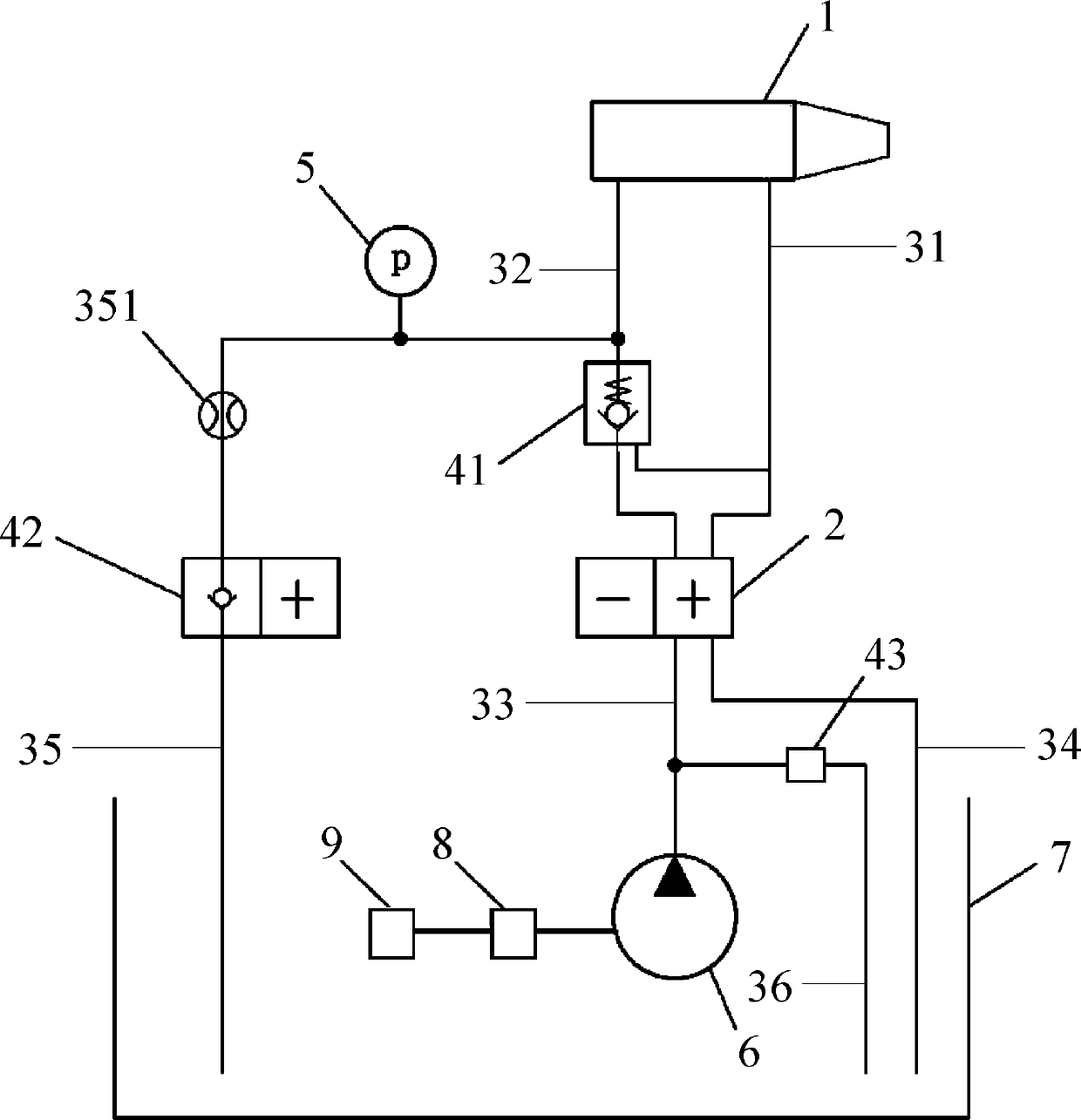

[0036] A high-precision load control device for supporting axial force, including a jack 1, a reversing valve 2, a ball valve 41, an unloading valve 42, a high-pressure relief valve 43, an oil pressure gauge 5, an oil pump 6, an oil tank 7, and a stepping motor 8 and controller 9, such as figure 1As shown, the specific structure is:

[0037] Reversing valve 2, ball valve 41, unloading valve 42, high pressure relief valve 43, oil pressure gauge 5, oil pump 6, oil tank 7, stepper motor 8 and controller 9 are integrated into a micro-NC pumping station, which can be connected to jack 1 To generate mechanical axial force, the above-mentioned micro numerical control pump station can be installed in the support head connected with the steel support to support the foundation pit enclosure structure.

[0038] The first oil inlet of the reversing valve 2 is connected to the oil inlet of the jack 1 through the first oil pipe 31, and the second oil inlet of the reversing valve 2 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com