Self-expansion type compaction pile construction method

A construction method and technology for compacting piles, applied in sheet pile walls, soil protection, infrastructure engineering, etc., can solve problems such as deteriorating foundation conditions, poor self-compactness, and difficulty in impact reaming quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in combination with specific embodiments.

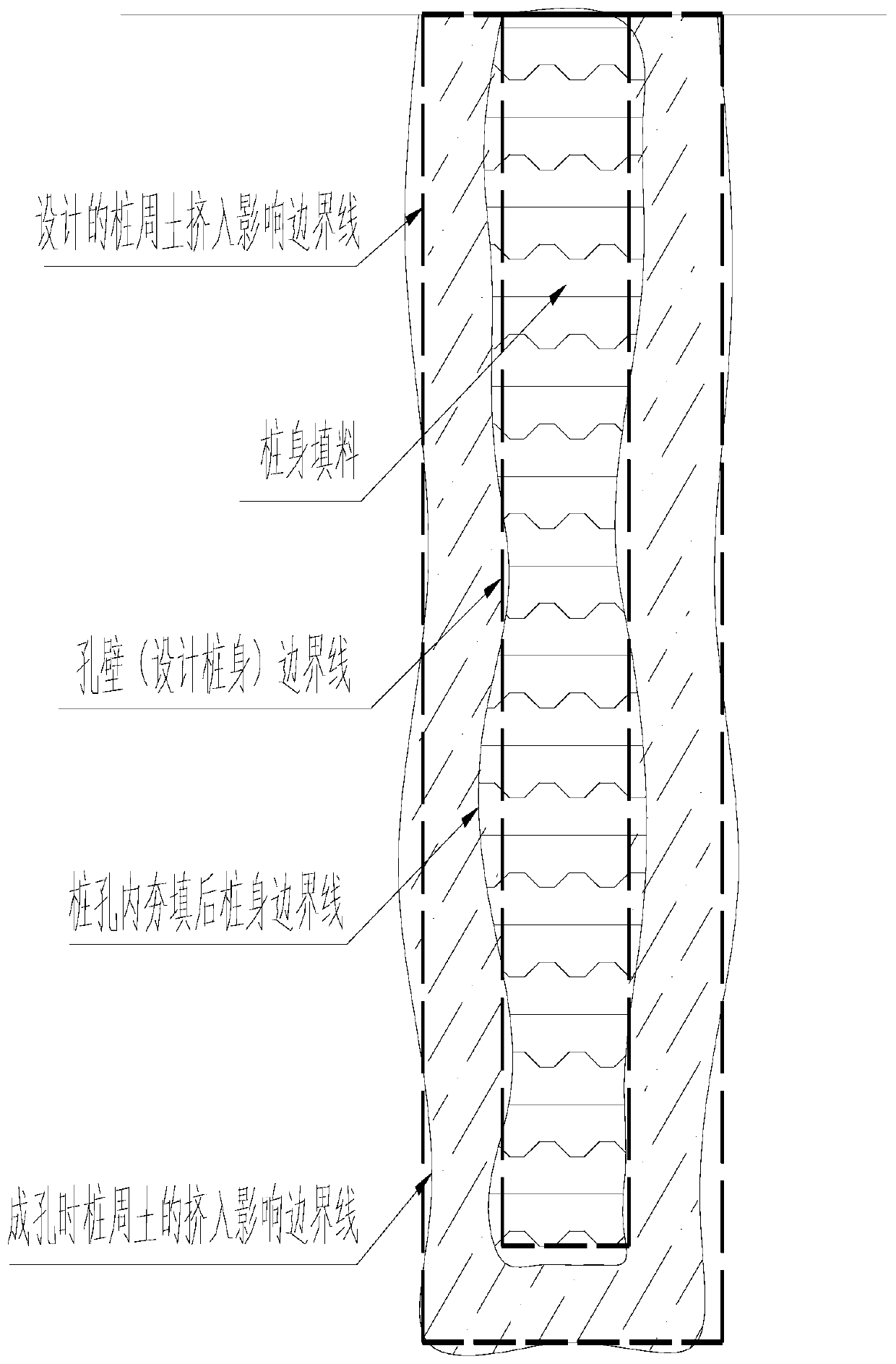

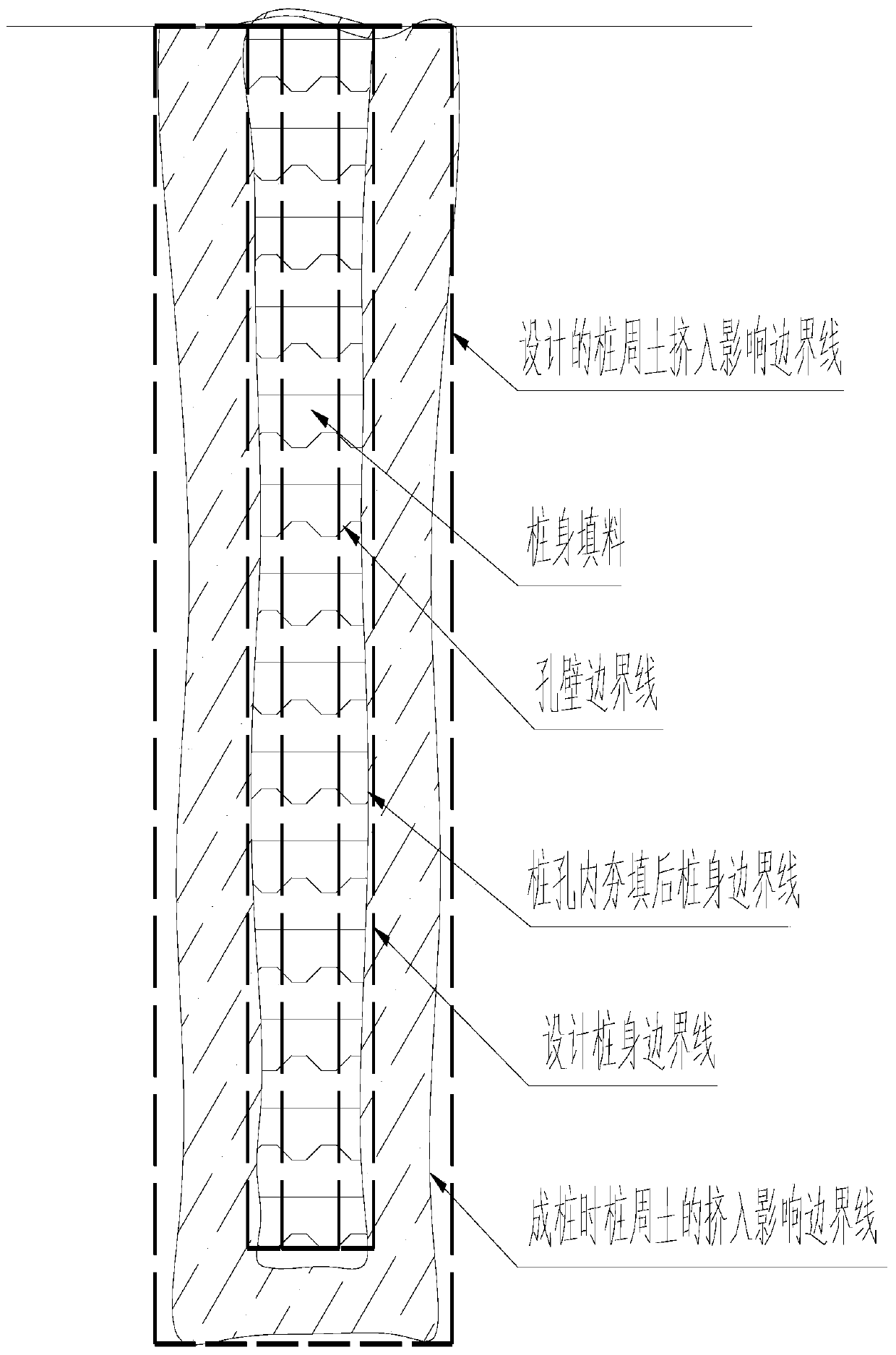

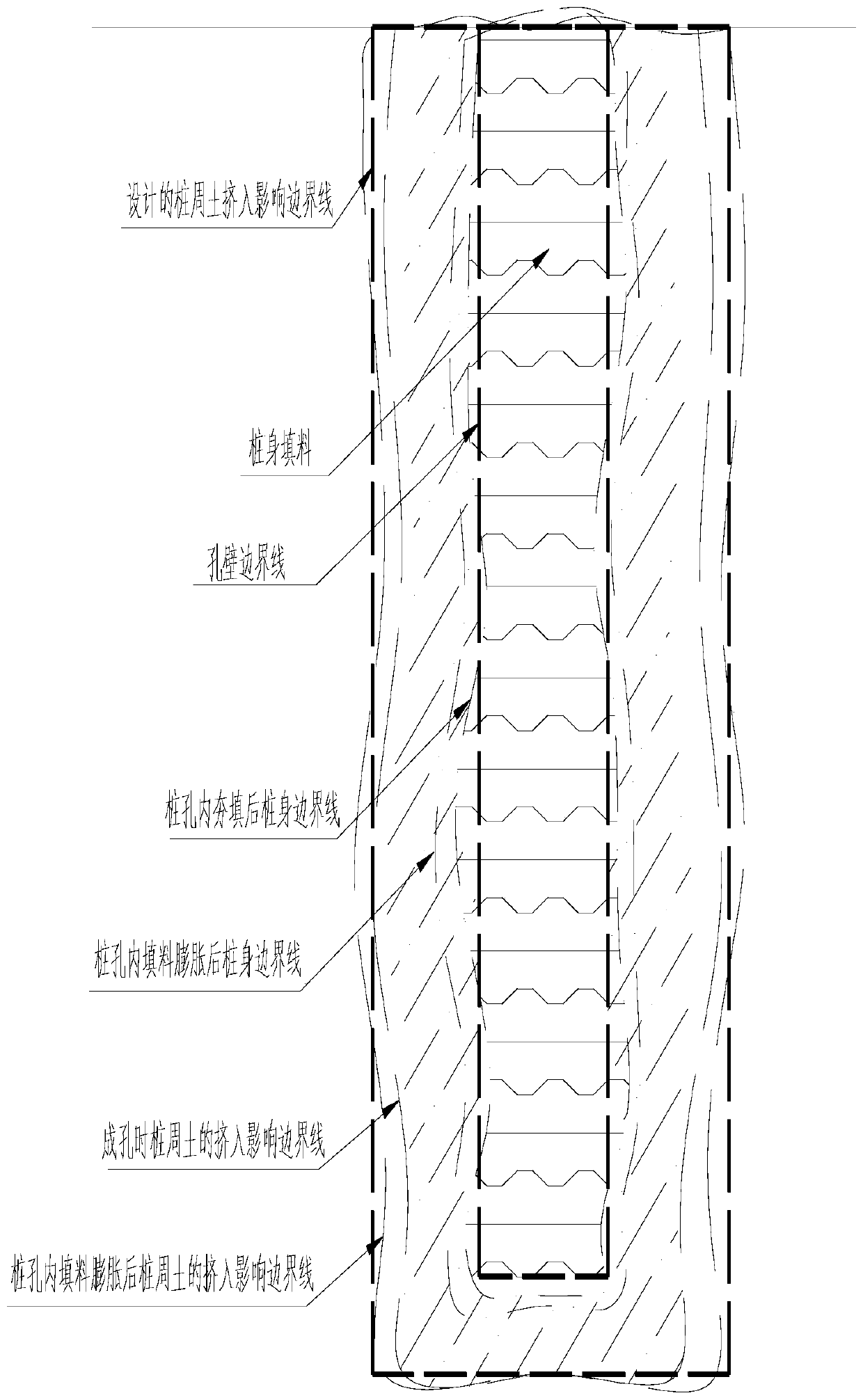

[0031] The self-expanding compaction pile material of the present invention can use the material properties of quicklime (quicklime) and other materials that expand in volume when encountering water (but will not shrink again), and can be combined with gravel or gravel (gravel) materials with better self-tightness. Mixing, and properly adding cement (cement), fly ash (Fly ash) and other cementitious materials, using the existing construction technology of compaction piles or column hammer punching expansion piles (including pre-drilled compaction piles), the pile body is divided into After the layer tamping is completed, the pile body is image 3 , 4, "Boundary line of the pile body after tamping and filling in the pile hole", after the pile body material absorbs the water in the soil, the material itself expands, making the foundation soil further compacted, that is, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com