Screw pile

A screw and pile technology, applied in the field of foundation engineering, can solve the problems of inconvenient installation, difficult removal, and no bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0026] The technical solutions provided by the embodiments of the present invention are described below with reference to the accompanying drawings.

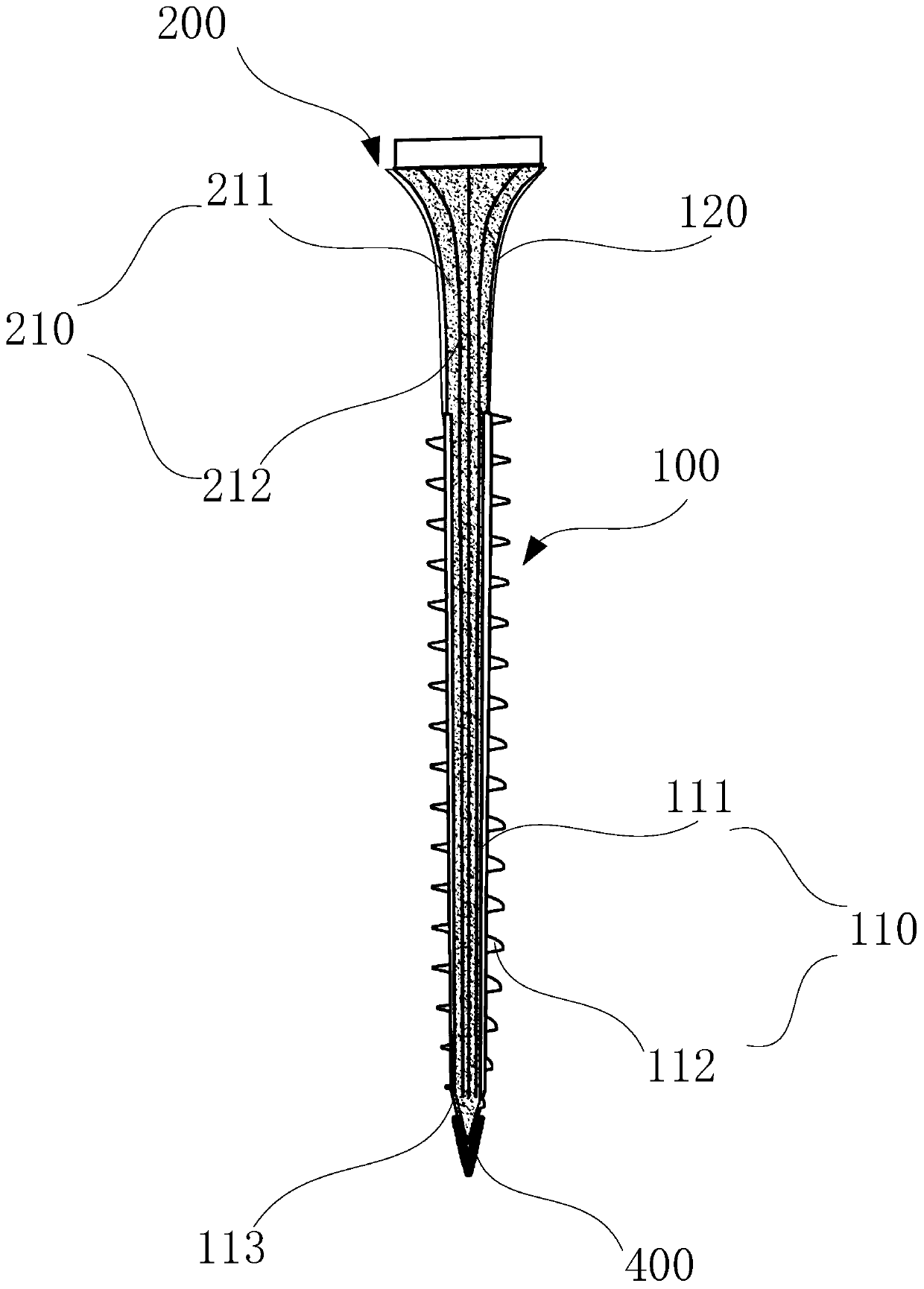

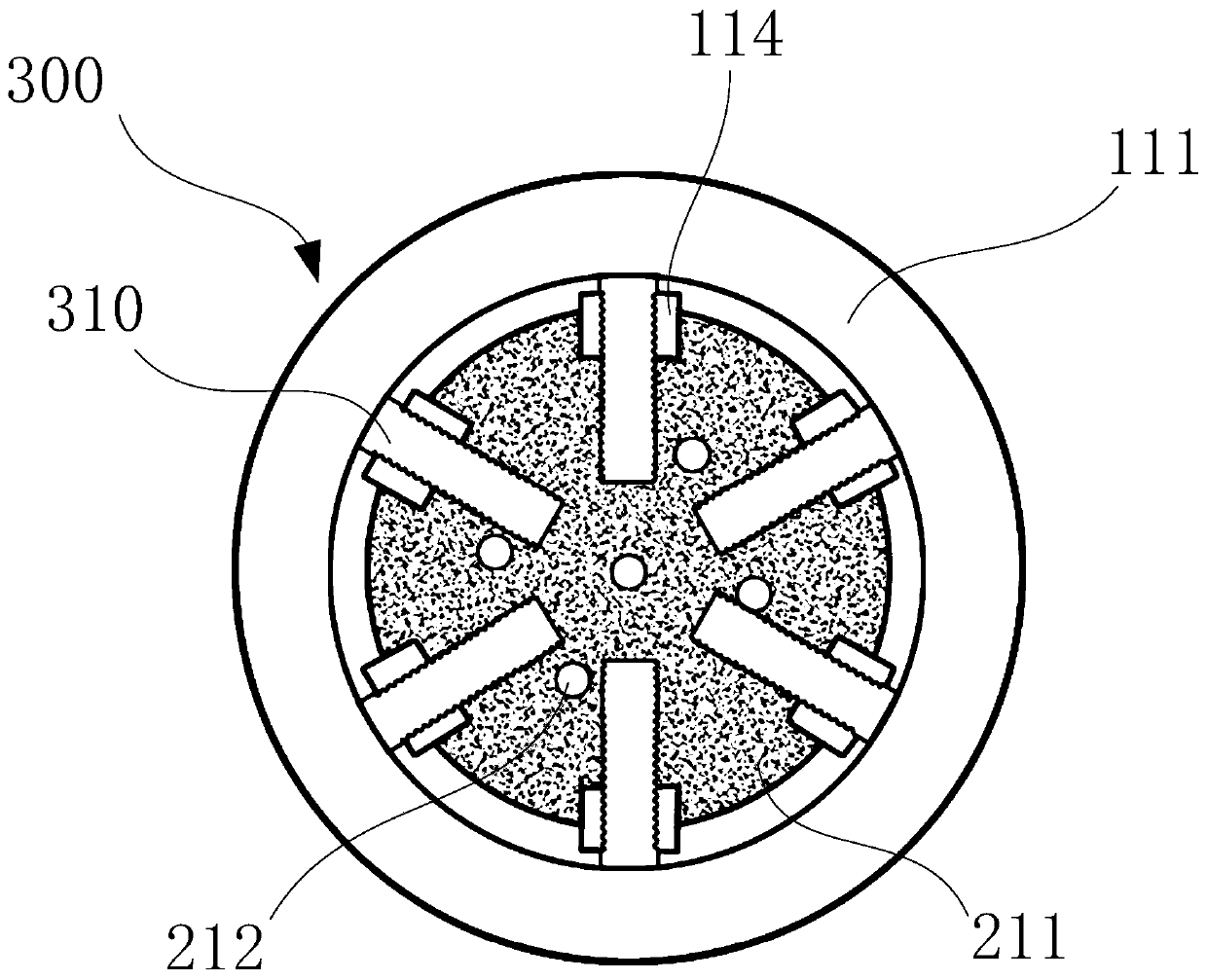

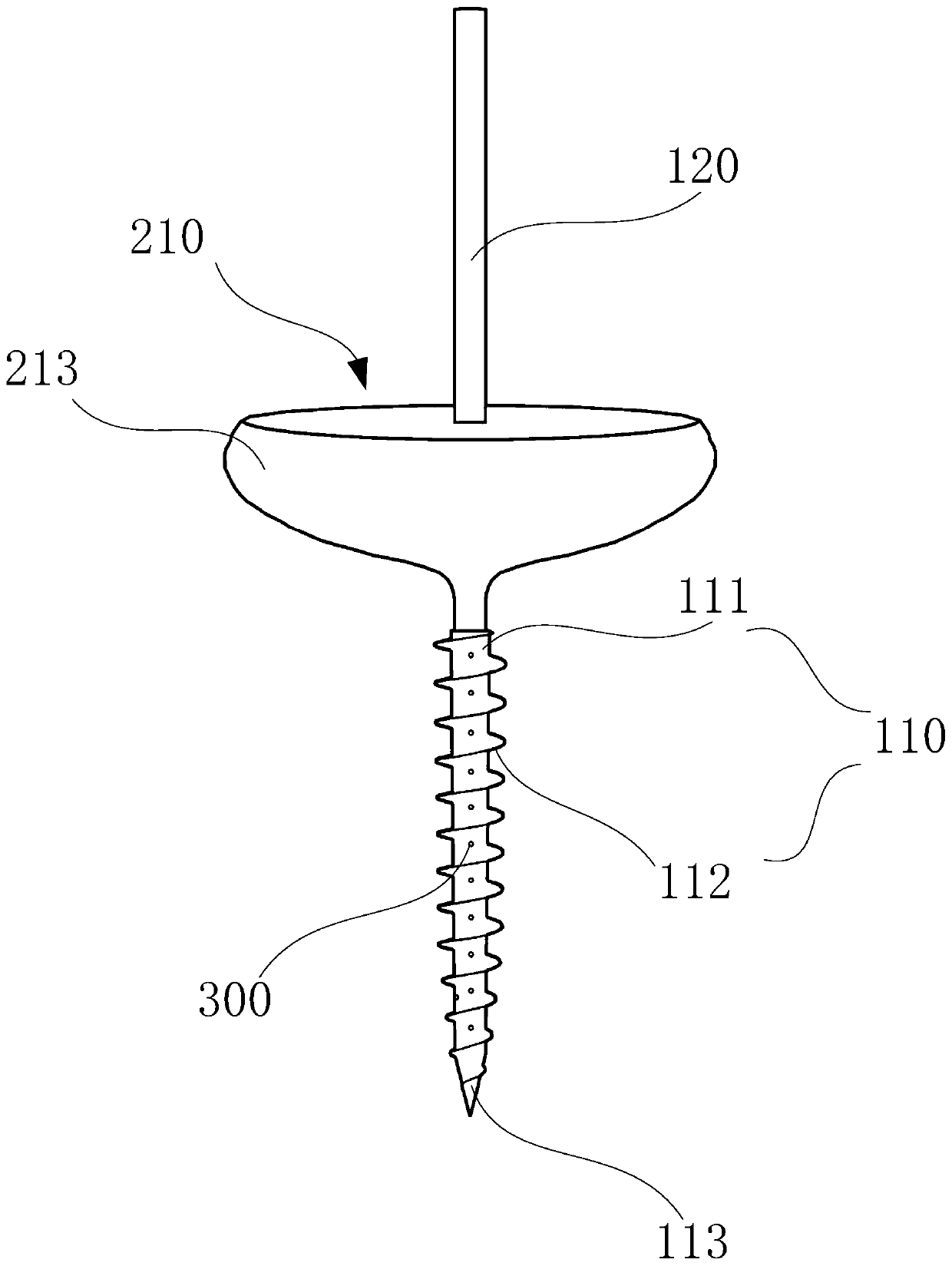

[0027] Such as figure 1 as well as figure 2 As shown, a screw pile is applied to soil foundation treatment, including an outer pile body 100, a pile core 200 and a fastener 300, wherein:

[0028] Outer pile body 100 comprises first pile body 110 at least, and first pile body 110 adopts engineering plastics to prepare, and engineering plastics can have multiple options, as PP (polymer polypropylene), PE (polyethylene), PVC (polyvinyl chloride) ), ABS (acrylonitrile-butadiene-styrene), glass fiber reinforced pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com