Assembling method for steel-concrete composite pipe thin-wall steel plate hole flanging, taping and screw connection

An assembly method and technology of composite pipes, which are applied in the direction of construction and building construction, can solve the problems of increased weight and cost and large thickness of steel-concrete composite pipes, and achieve the effects of compact structure, reduced weight and cost, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

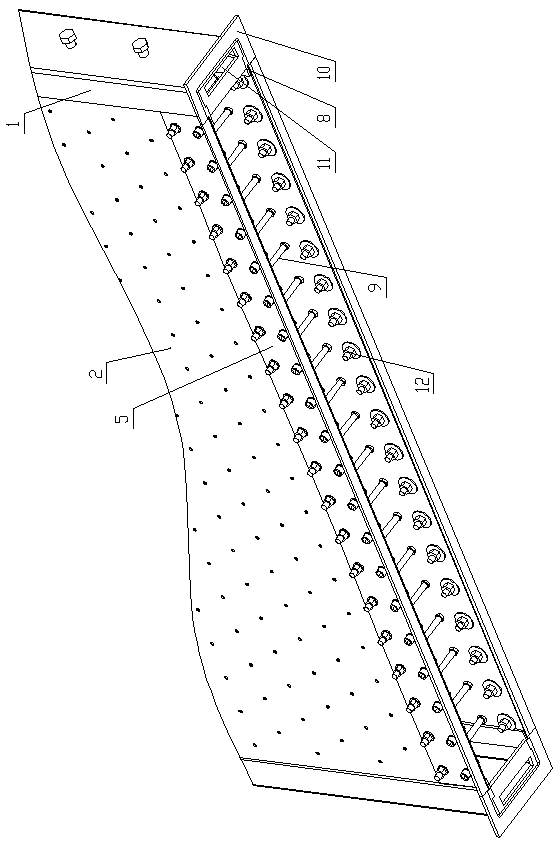

[0022] Such as figure 1 and figure 2 As shown, the assembly method of the steel-concrete composite pipe thin-walled steel plate turning and tapping screw connection of the present invention, the steel-concrete composite pipe includes two channel steels 1 arranged along the vertical direction, and the openings of the two channel steels 1 The left and right are oppositely arranged, and a rectangular steel plate 2 is respectively arranged between the front side and the rear side of the two channel steels 1, and the described assembly method includes the following steps,

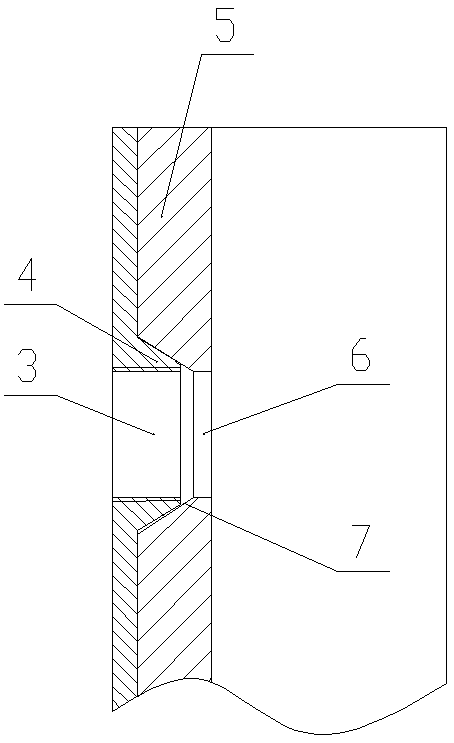

[0023] (1) The thickness of the two steel plates 2 is 1-3 mm, and several perforations 3 are formed on the two steel plates 2 by the process of turning holes to form a conical flanging structure 4. Several perforations 3 are arranged in a rectangular array, and The hole wall tapping of the perforation 3; at the same time, four angle steel flanges 5 equal to the length of the steel plate 2 in the horizontal dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com