Linear compressor

A linear compressor and compressor technology, applied in the field of compressors, can solve problems such as performance degradation, achieve the effects of low cost, easy processing, and improved performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

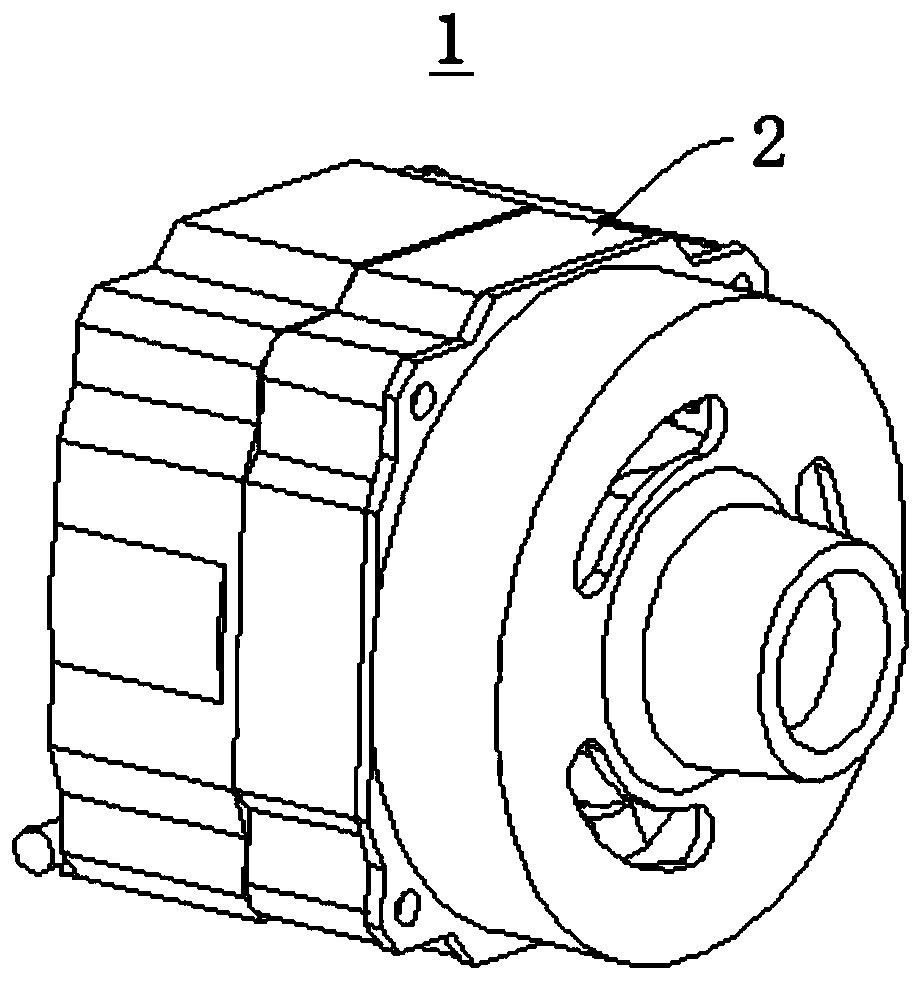

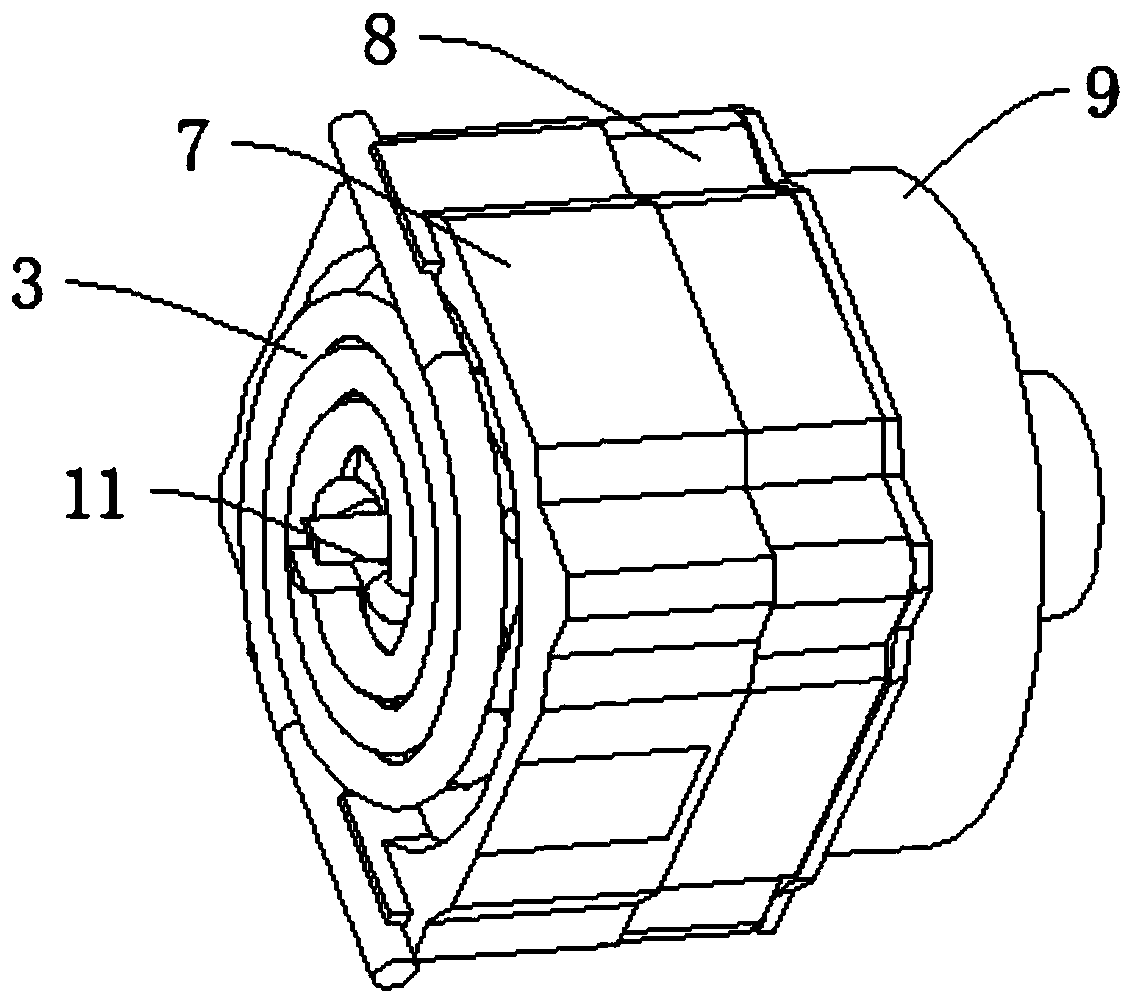

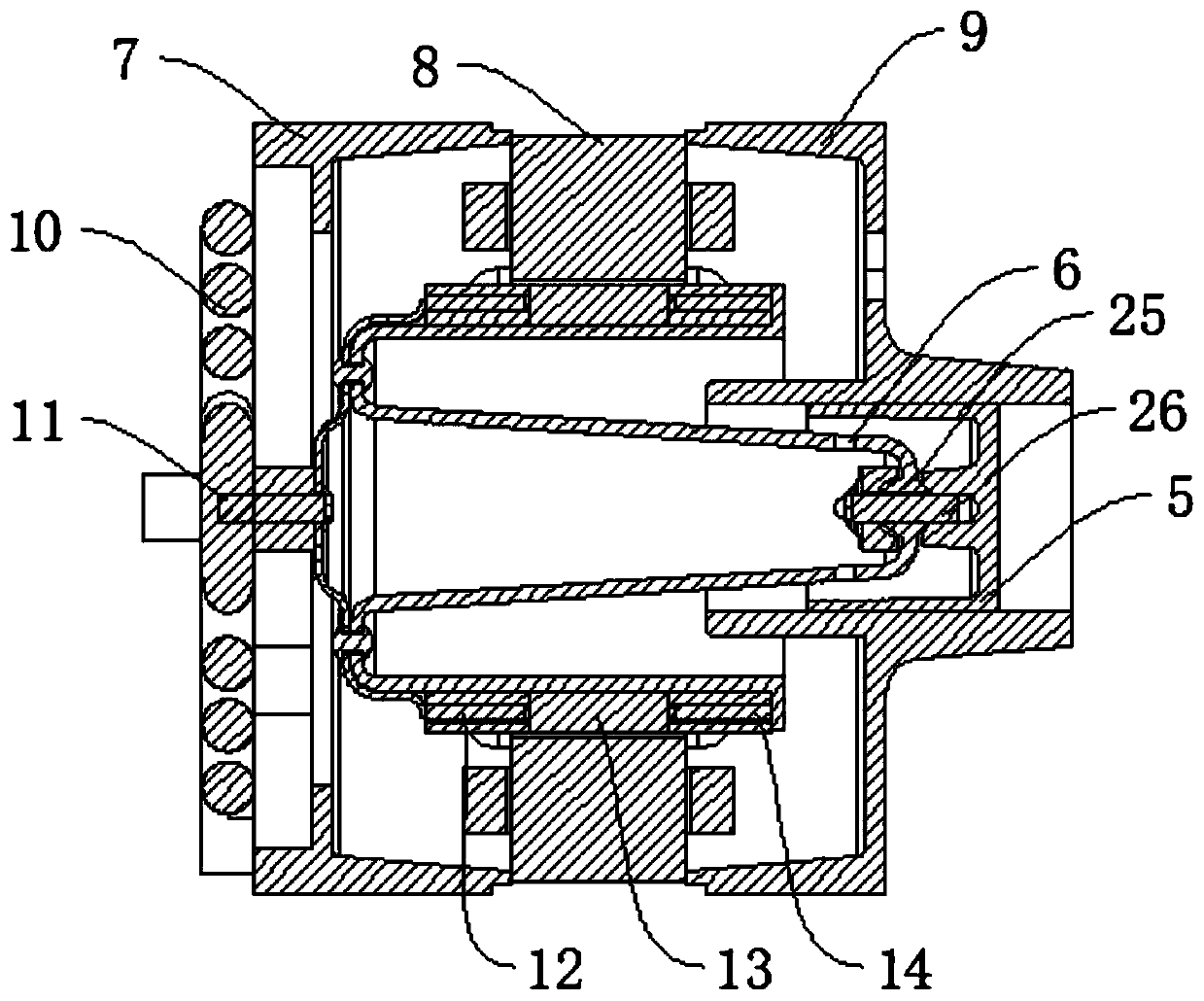

[0039] Please refer to figure 1 , with reference to Figure 2 to Figure 6 , the present application provides a linear compressor 1, which mainly includes a motor assembly 2, a resonance assembly 3, a mover assembly 4, a piston 5, and a connection assembly 6; wherein, the mover assembly 4, the piston 5, and the connection assembly 6 are all arranged in In the motor assembly 2 , the mover assembly 4 is sleeved on the connecting cylinder 15 , the resonance assembly 3 is installed on the outer end of the motor assembly 2 and communicated with the suction cylinder 19 , and the piston 5 is communicated with the suction cylinder 19 .

[0040] Please refer to figure 1 , with reference to figure 2 and image 3 , the motor assembly 2 includes a motor base 7, a motor stator 8, and a cylinder structure 9 connected in sequence, and the three can be connected by bolts, or can be connected by a buckle connection; at the same time, the motor base 7, the motor The stator 8 and the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com