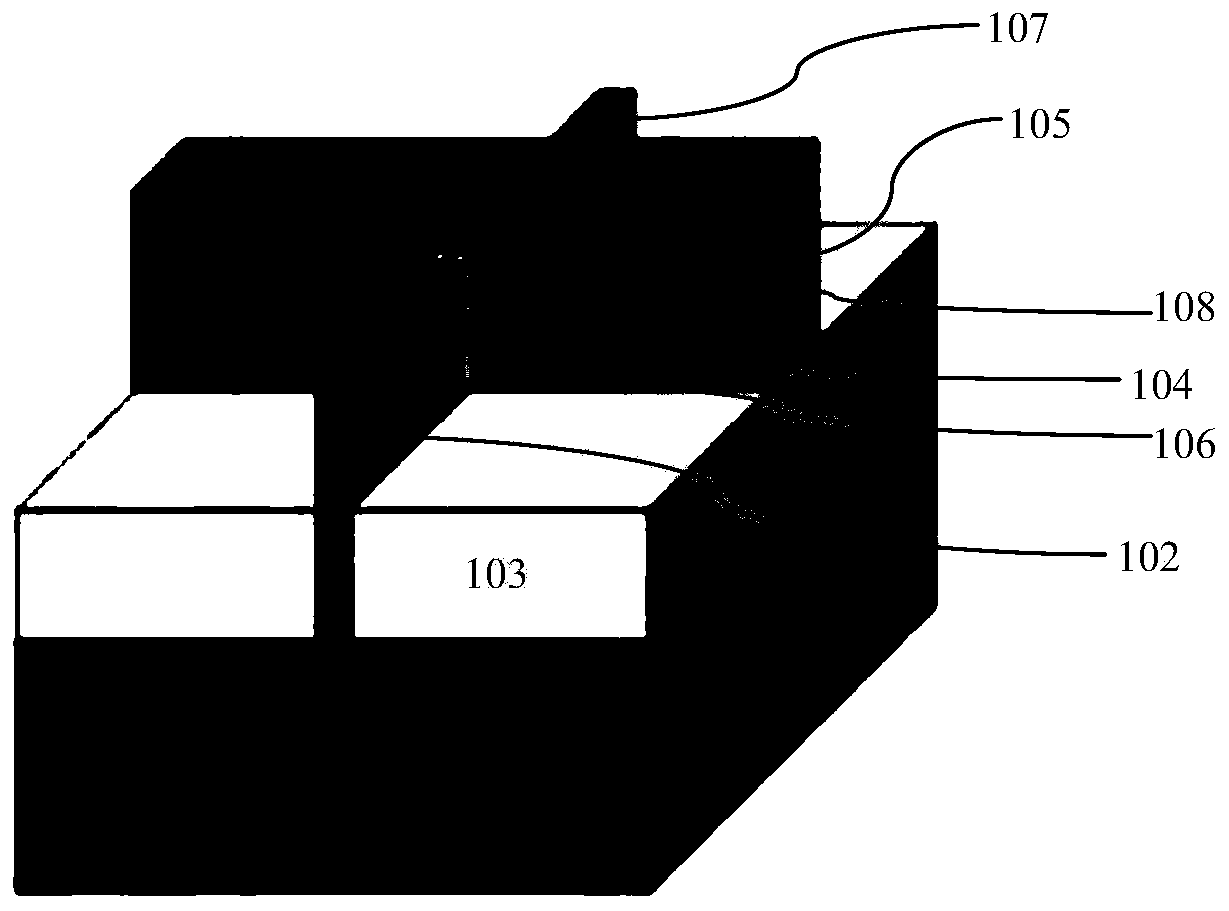

Width measuring method for nano-strip or nano-sheet of semiconductor device

A measurement method and nano-stripe technology, applied in measurement devices, instruments, etc., can solve the problems of general electrical yield connection, slow measurement speed, and small number of samples, and achieve fast test speed, good yield, and simple test. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

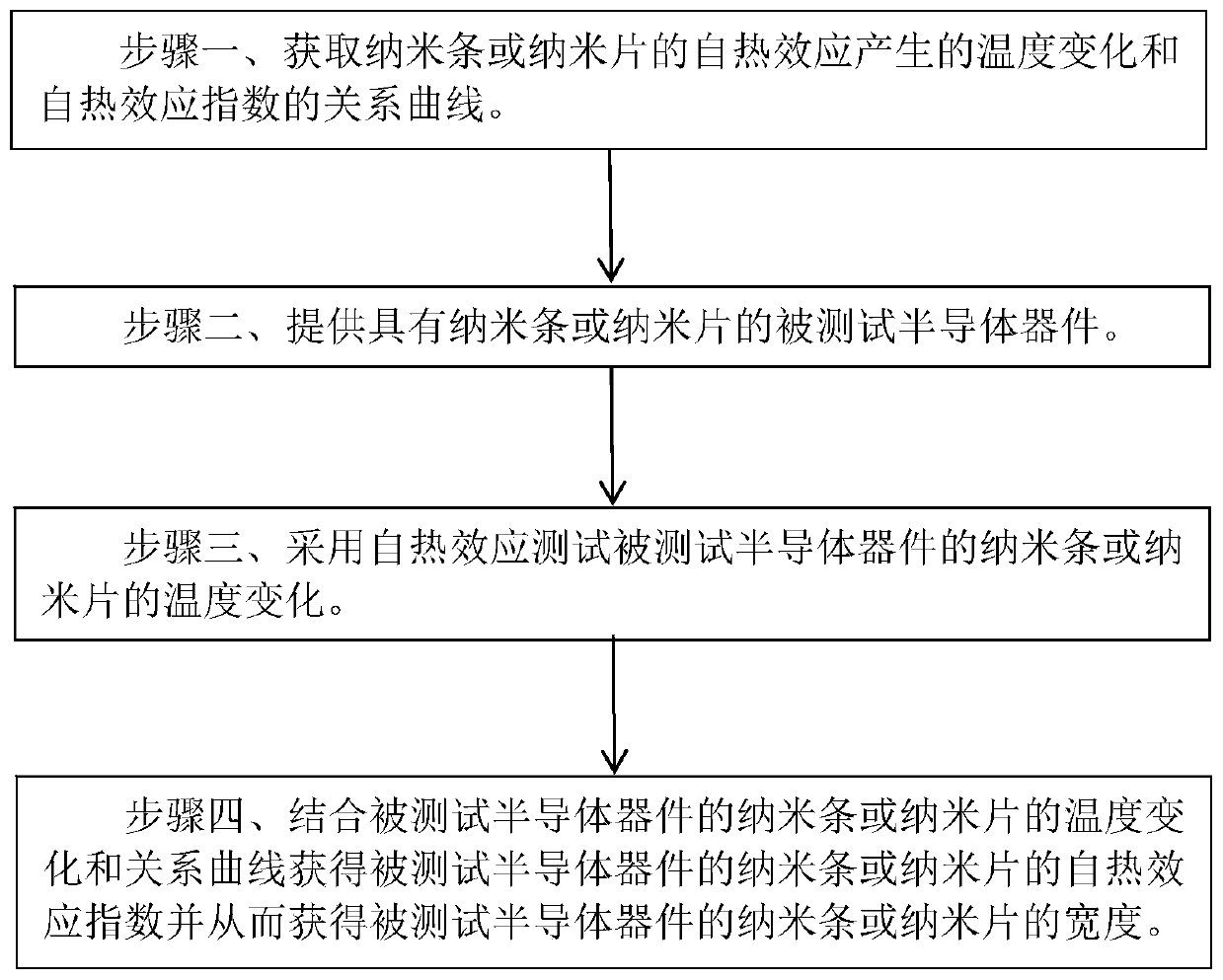

[0033] Such as figure 2 Shown is a flowchart of a method for measuring the width of a nanobar or a nanosheet of a semiconductor device according to an embodiment of the present invention; the method for measuring the width of a nanobar or a nanosheet of a semiconductor device according to an embodiment of the present invention includes the following steps:

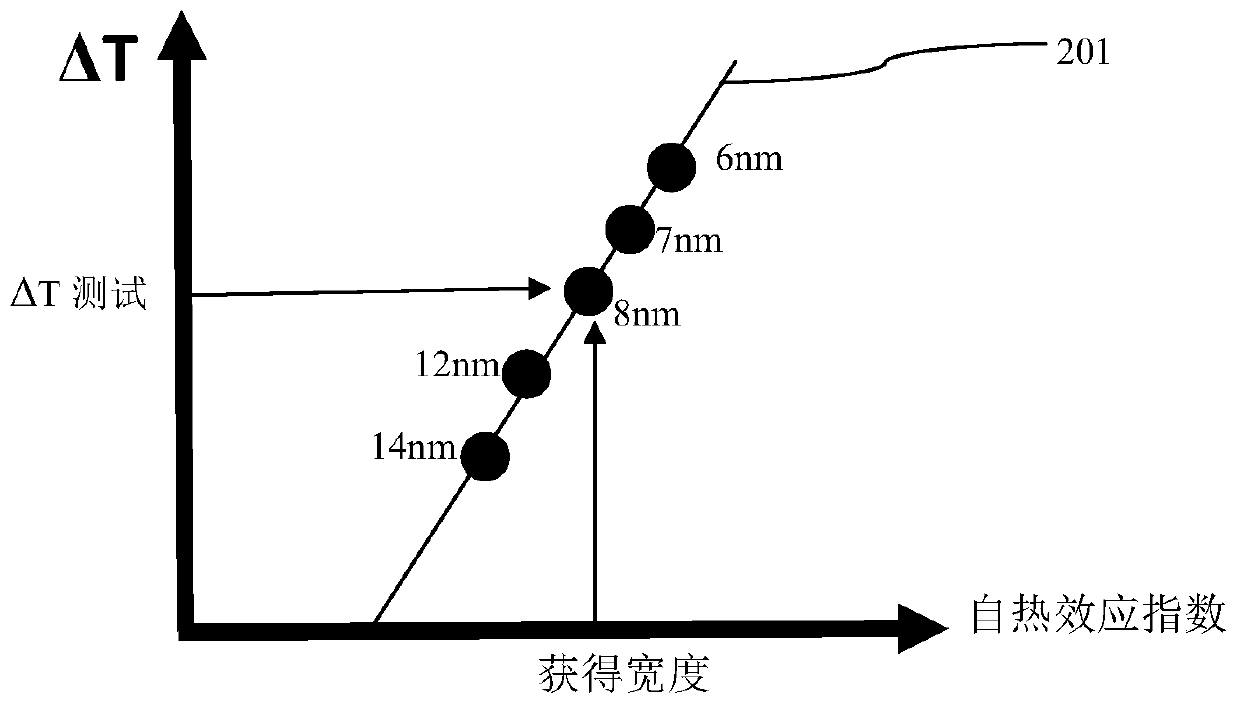

[0034] Step 1. Obtain a relationship curve between the temperature change caused by the self-heating effect of the nano-strips or nano-sheets and the self-heating effect index; the self-heating effect index is related to the height and width of the nano-strips or nano-sheets. The self-heating effect index is proportional to the ratio of the height and width of the corresponding nanorods or nanosheets.

[0035] In the embodiment of the present invention, the linear regression model in which the temperature change and the self-heating effect index have a linear relationship is obtained through the relationship curve; the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com