Display substrate, preparation method thereof, and display device

A technology for display substrates and driving substrates, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low efficiency of Micro-LED, excessive amount of solder paste, low yield, etc., to avoid N pole The effect of short circuit with P pole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

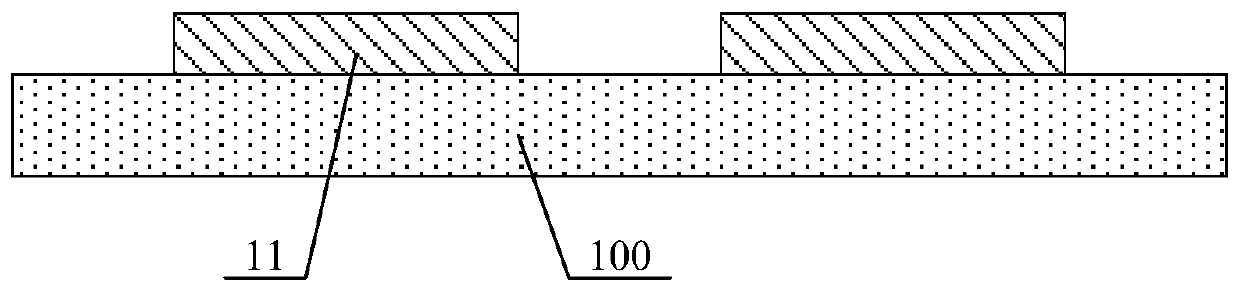

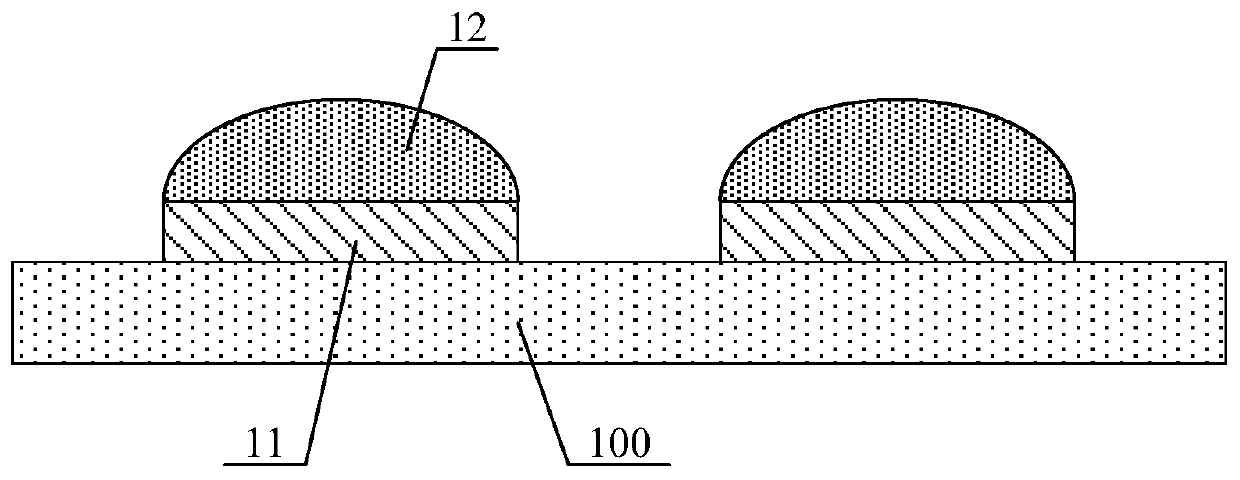

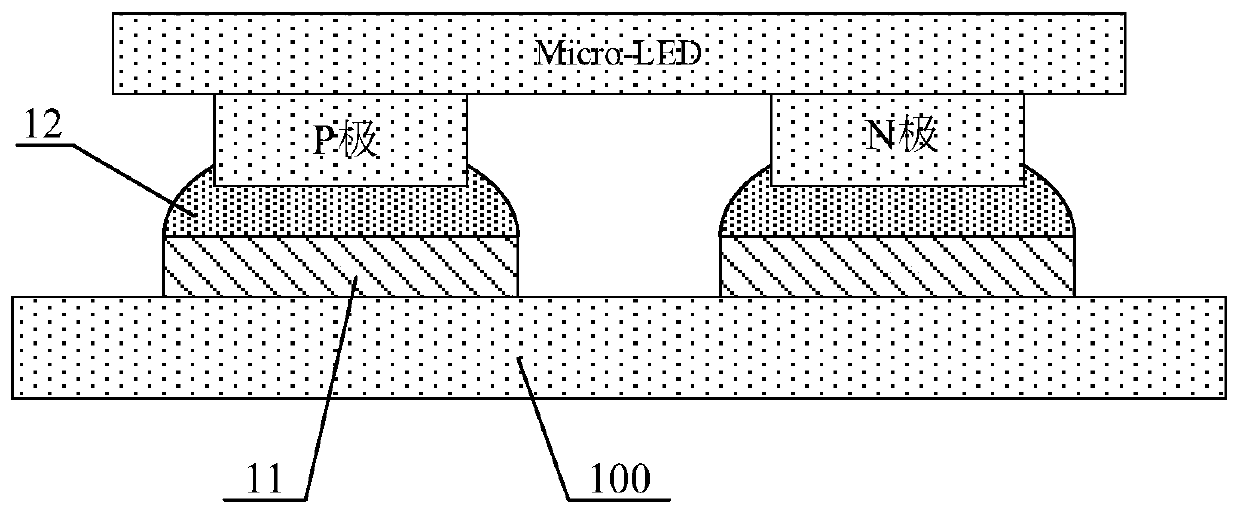

[0069] figure 2 A schematic structural diagram of the substrate is shown for the first embodiment of the present invention. Such as figure 2 As shown, the display substrate includes a driving substrate 100 and a bonding pad 11 disposed on the driving substrate 100 , and the bonding pad 11 is electrically connected to the driving substrate 100 . The display substrate further includes an insulating structure layer 21 disposed on the welding pad 11 , and the insulating structure layer 21 is provided with a groove 22 exposing the welding pad 11 . Binding material 23 is accommodated in the groove 22 , and the pins of the micro LEDs are electrically connected to the welding pads 23 through the binding material 23 .

[0070] In the display substrate of the embodiment of the present invention, when the Micro-LED is bound and connected to the display substrate, the dispenser can be controlled to place the binding material such as solder paste in the groove 22, and the groove 22 can...

no. 2 example

[0092] Figure 4A schematic structural diagram of the substrate is shown for the second embodiment of the present invention. The difference from the first embodiment is that if Figure 4 As shown, in this embodiment, the display substrate further includes a metal connection layer 24 disposed in the groove 22 , the metal connection layer 24 is in contact with both the bottom surface and the side surface of the groove, and the metal connection layer 24 is electrically connected to the welding pad 11 . The inner side of the metal connection layer 24 forms a sub-groove 25 corresponding to the groove 22, and the binding material is accommodated in the sub-groove 25, and the micro light-emitting diode is electrically connected to the metal connection layer 24 through the binding material 23, and then electrically connected to the welding pad. connect.

[0093] In the display substrate of the embodiment of the present invention, when the binding material 23 is dotted into the sub-g...

no. 3 example

[0126] Based on the inventive concepts of the aforementioned embodiments, an embodiment of the present invention further provides a display device, which includes the display substrate using the aforementioned embodiments. The display device can be any product or component with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com