Electric connector

An electrical connector and electrical connection technology, applied in the direction of connection and connection device components, circuits, etc., can solve the problems of limiting transmission rate, affecting high-frequency characteristics, long terminal current path, etc., to improve high-frequency characteristics, The effect of improving the transmission speed and shortening the current path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

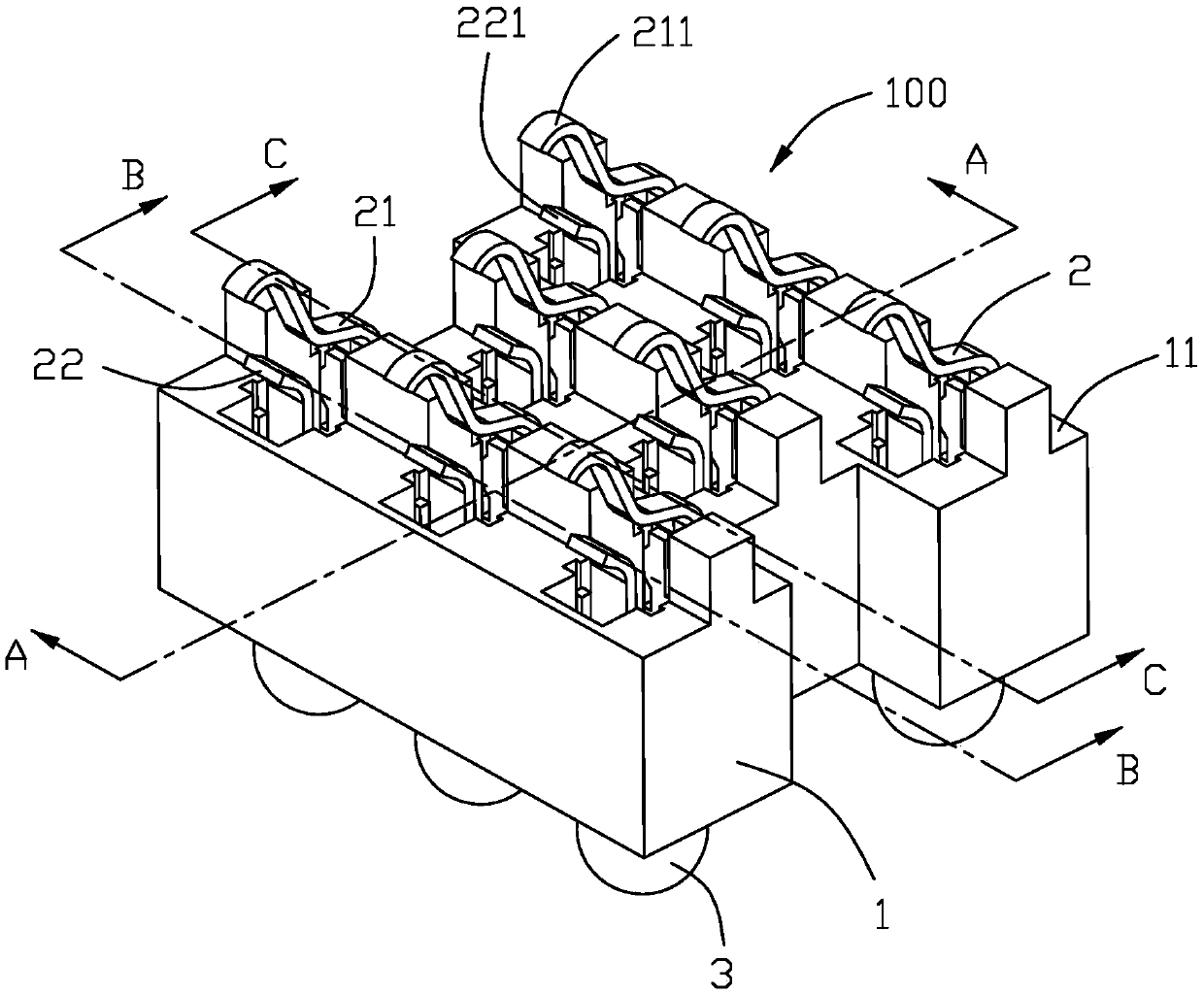

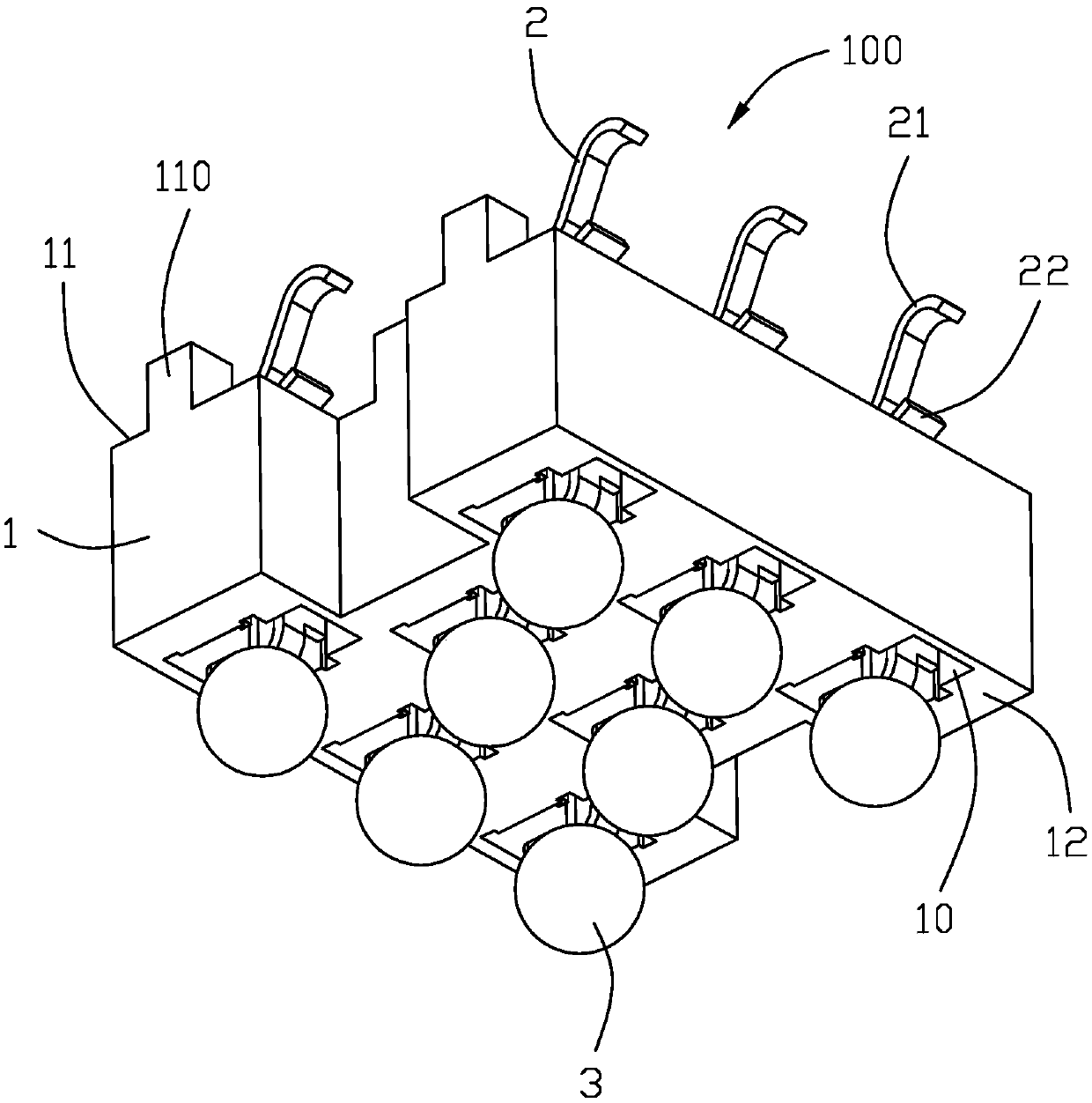

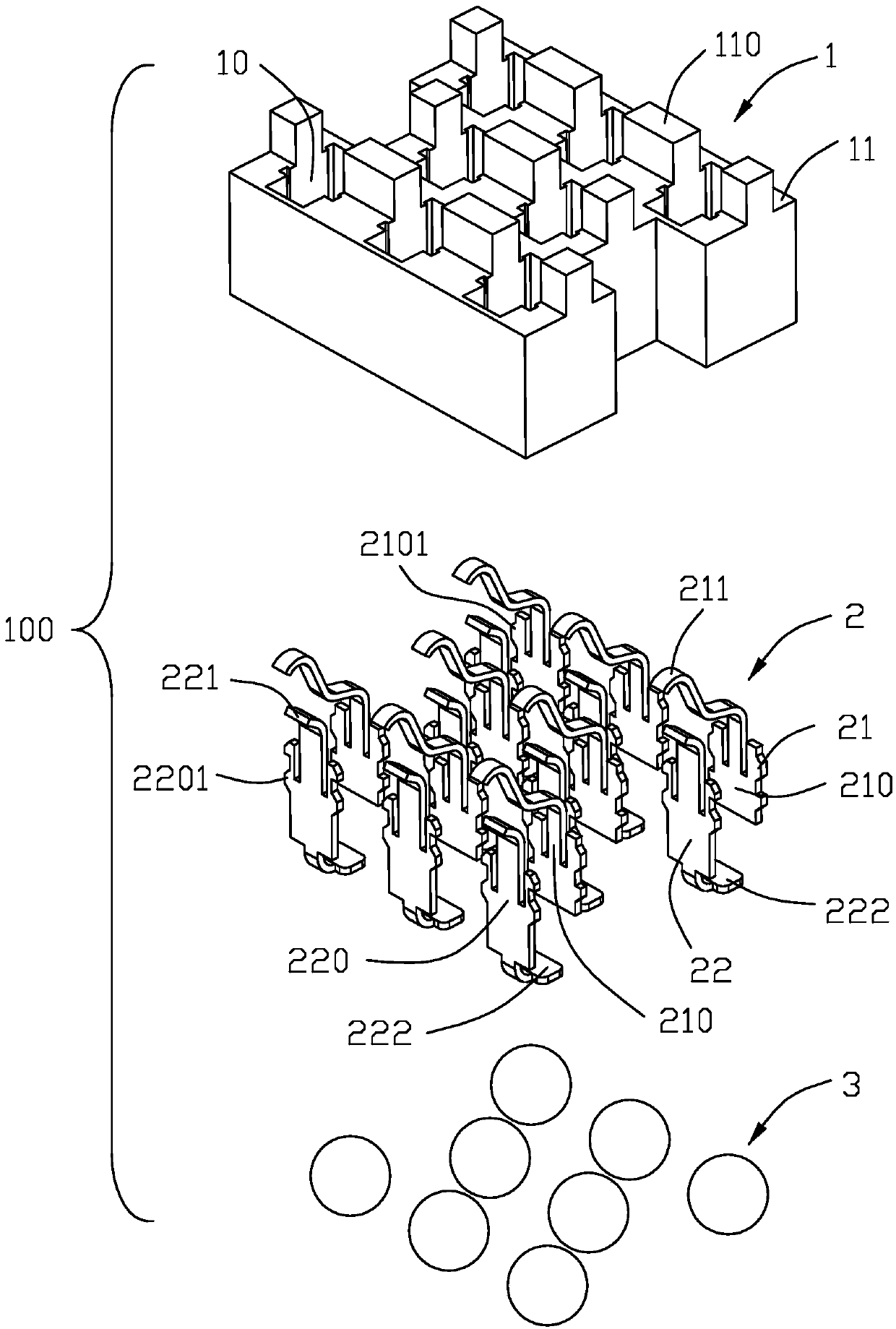

[0040] Below, will combine Figure 1 to Figure 9 The specific implementation manner of the electrical connector of the present invention is introduced.

[0041] The electrical connector 100 of the present invention is used for soldering to a circuit board (not shown) to electrically connect a chip module 200, such as Figure 1 to Figure 7 As shown, the electrical connector 100 includes an insulating body 1 having a plurality of terminal holes 10 and a plurality of conductive terminals 2 accommodated in the terminal holes 10 in a one-to-one correspondence. The insulating body 1 has an upper surface 11 and a lower surface 12 opposite to each other, and the terminal hole 10 penetrates the upper and lower surfaces 11 , 12 . The conductive terminal 2 includes a docking arm 21 for contacting the chip module 200 and a welding arm 22 extending up and down for welding to the circuit board. The first body part 210 in the hole 10 and the elastic arm 211 bent upward from the first body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com