A restraining device for heaving motion of semi-submersible platform

A technology of semi-submersible platform and suppression device, which is applied in the direction of equipment for reducing ship movement, transportation and packaging, floating buildings, etc. It can solve the problems of large riser fatigue damage, small additional mass, and limited suppression effect, and achieve good results. The effect of vibration suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

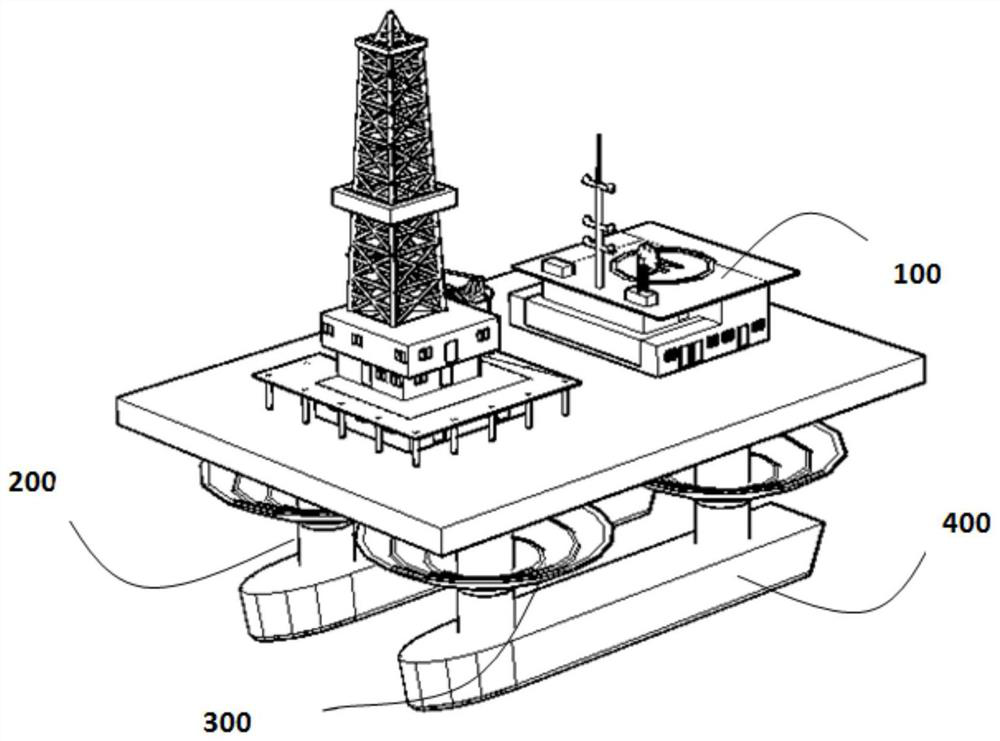

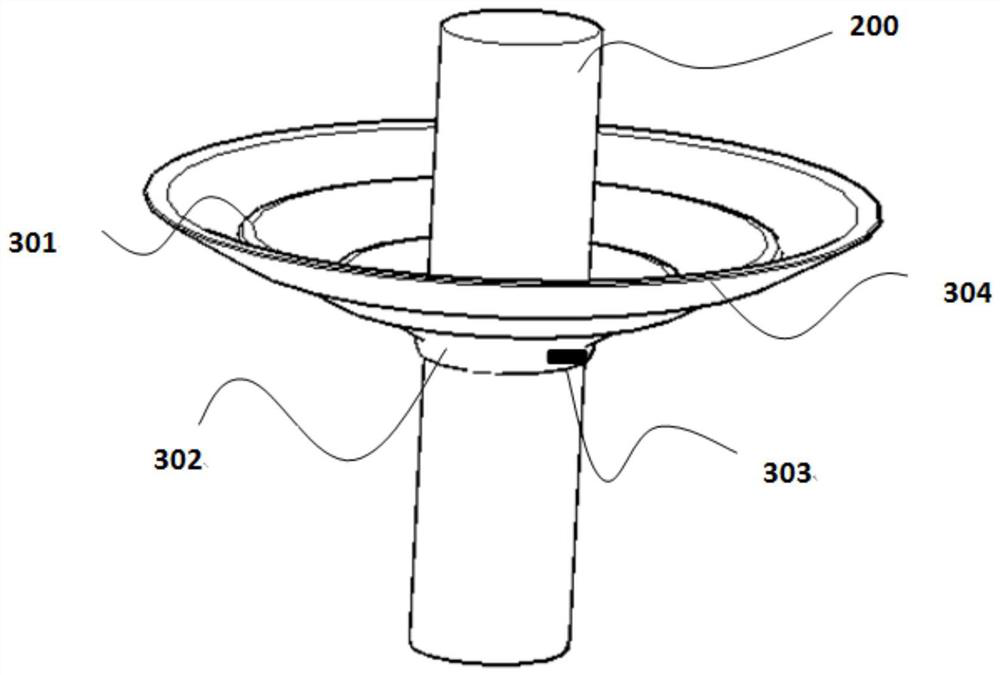

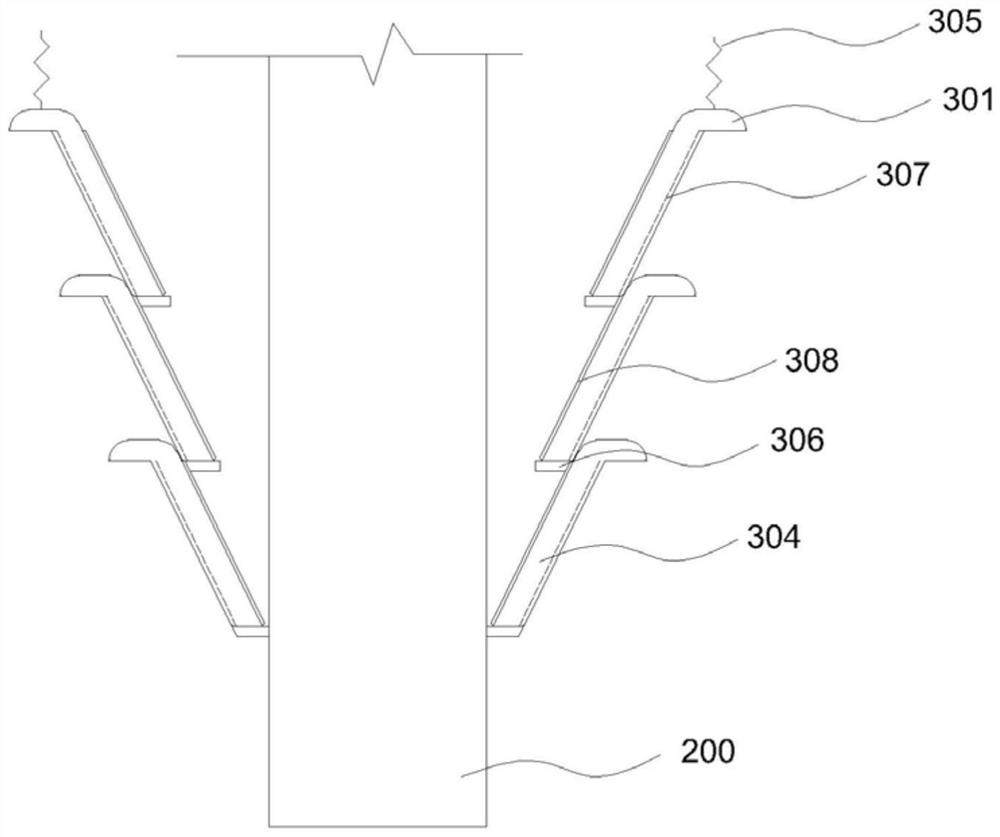

[0024] Such as Figure 1-3 As shown, a device for suppressing the heaving motion of a semi-submersible platform includes an upper platform structure (100), and a lower floating body (400) is connected below the upper platform structure (100) through a column (200), and the column ( 200) is provided with a heave suppression mechanism that reduces the heave motion of the platform by changing the natural period of the heave of the platform and the flow field around the column (200).

[0025] The heave suppression mechanism is an extendable annular heave plate (300) which is arranged on the column (200) and forms a certain angle with the column, and an electric rope winch. The electric rope winch is provided with a steel wire rope (305) and a Stretching the annular heave plate (300) is connected. The electric winch is installed above the upper platform structure (100). The main function of the above-mentioned stretchable heave plate structure with variable inclination is to dest...

Embodiment 2

[0033] Such as Figure 4-5 As shown, a device for suppressing the heaving motion of a semi-submersible platform includes an upper platform structure (100), and a lower floating body (400) is connected below the upper platform structure (100) through a column (200), and the column ( 200) is provided with a heave suppression mechanism that reduces the heave motion of the platform by changing the natural period of the heave of the platform and the flow field around the column (200).

[0034] The heave suppression mechanism is an active tuning mass damper, and the active tuning mass damper includes a power system, a tuning control system (500), a damping system, a spring system (600), and a variable mass floating body (700), wherein : The damping system is formed by utilizing the water body around the variable mass floating body, the variable mass floating body (700) is sleeved on the column (200), and the inner diameter of the variable mass floating body (700) is greater than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com