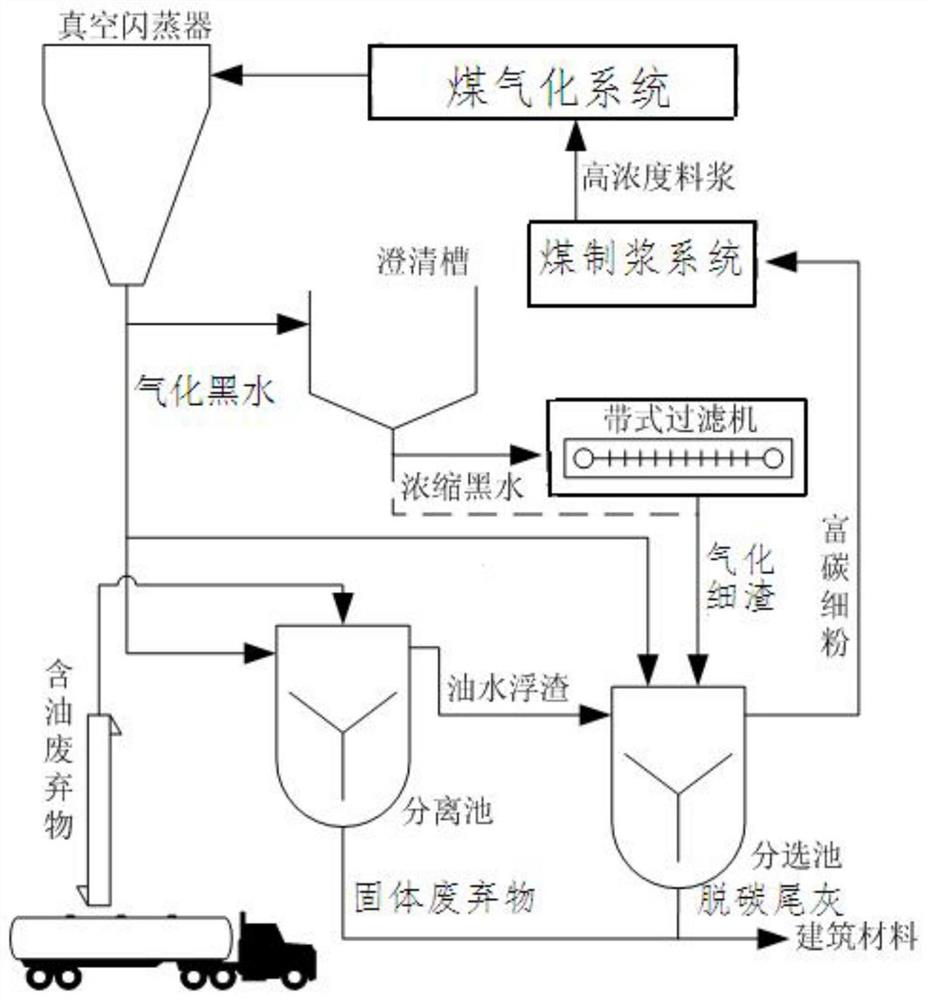

Thermal washing of oily waste based on gasification black water-integrated process of high-value utilization of fine slag

A waste and black water technology, applied in the gasification process, petroleum industry, chemical industry, etc., can solve the problems of low calorific value of refined carbon, poor economic benefits of boiler blending, and unexplained specific flotation process. Achieve the effect of reducing the cost of flotation, improving the promotion value and application prospects, and achieving significant comprehensive economic and environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment includes the following steps:

[0026]Step 1. Obtain gasified black water from the outlet of the vacuum flasher in the coal gasification system of a chemical plant in Guanzhong area, and mix the oily waste with a flow rate of 2058.46kg / h with the gasified black water with a flow rate of 10292.3kg / h Then send it to the combined air flotation separation tank for solid-liquid separation to obtain oil-water scum and solid waste, and send the oil-water scum to the sorting tank; the temperature of the gasified black water is 80 ° C, and the pH value is 7 , the oil-water scum contains hydrocarbon substances; the oily waste is the oily sludge cleaned from the tank bottom of a refinery in northern Shaanxi, and the mass percentage of water in the oily waste is 40.24%. The mass percentage of such inorganic precipitates is 25.01%, and the content of hydrocarbons is 24.87%;

[0027] After testing, the residual oil rate of the solid waste obtained in this example is ...

Embodiment 2

[0032] This embodiment includes the following steps:

[0033] Step 1. Obtain gasified black water from the outlet of the vacuum flasher in the coal gasification system of a chemical plant in Guanzhong area, and mix the oily waste with a flow rate of 5876.58kg / h with the gasified black water with a flow rate of 5876.58kg / h Then send it to the dissolved air flotation separation tank for solid-liquid separation to obtain oil-water scum and solid waste, and send the oil-water scum to the sorting tank; the temperature of the gasified black water is 40 ° C, and the pH value is 9 , the oil-water scum contains hydrocarbon substances; the oily waste is the oily sludge cleaned from the tank bottom of a refinery in northern Shaanxi, the mass percentage of water in the oily waste is 25.67%, and the solid precipitate The mass percentage of hydrocarbons is 20.43%, and the content of hydrocarbons is 40.56%;

[0034] After testing, the residual oil rate of the solid waste obtained in this ex...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] Step 1. Obtain gasified black water from the outlet of the vacuum flasher in the coal gasification system of a chemical plant in the Guanzhong area, and mix the oily waste with a flow rate of 2547.75kg / h with the gasified black water with a flow rate of 25477.5kg / h After that, it is sent to the combined air flotation separation tank for solid-liquid separation to obtain oil-water scum and solid waste, and the oil-water scum is sent to the sorting tank; the temperature of the gasified black water is 68 ° C, and the pH value is 8. The oil-water scum contains hydrocarbon substances; the oily waste is the oily sludge cleaned from the tank bottom of a refinery in northern Shaanxi. The mass percentage of water in the oily waste is 10.45%, and the solid The mass percentage of sediment is 52.78%, and the content of hydrocarbons is 11.24%;

[0041] After testing, the residual oil rate of the solid waste obtained in this exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| residual oil rate | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com