A zinc-coated hot-formed member with a tensile strength above 1800mpa and excellent cold-bending performance and a preparation method thereof

A technology for tensile strength and cold bending performance, applied in the field of zinc-coated thermoforming components and their preparation, can solve the problems of premature brittle fracture, increased strength, and adverse occupant safety of cold bending performance parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Table 2 Preparation process parameters before thermoforming

[0054]

[0055] Table 3 Properties of steel sheet or strip before hot forming

[0056]

[0057] Table 4 Thermoforming process parameters

[0058]

[0059] Table 5 Mechanical properties after thermoforming

[0060]

[0061] The thermoforming heating temperature and heating holding time in Example 1 were respectively changed to the values in Table 6, and the Γ phase ratio (%) of the resulting zinc-coated thermoformed member is shown in Table 6.

[0062] The relationship between table 6Γ phase ratio and heating temperature and time

[0063] Example Heating temperature °C Holding time min Γ phase ratio% 1 860 5 24.63 2 880 5 8.04 3 890 3 40.44 4 890 4 23.07 5 890 5 7.27 6 890 6 1.17 7 890 7 0.00

[0064] It can be seen from Table 6 that under the same holding time condition, the Γ phase decreases with the increase of the heating...

Embodiment 3

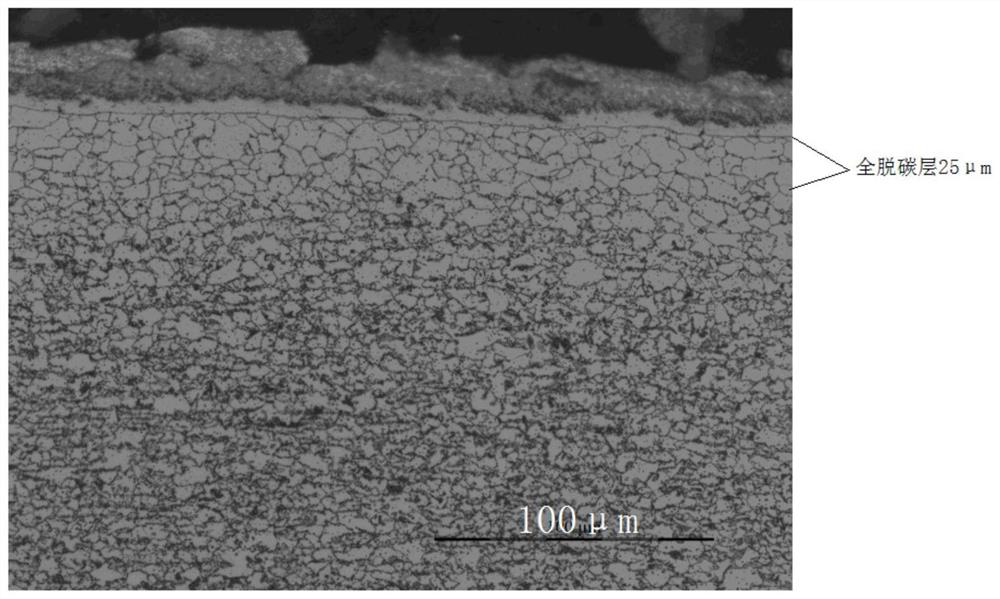

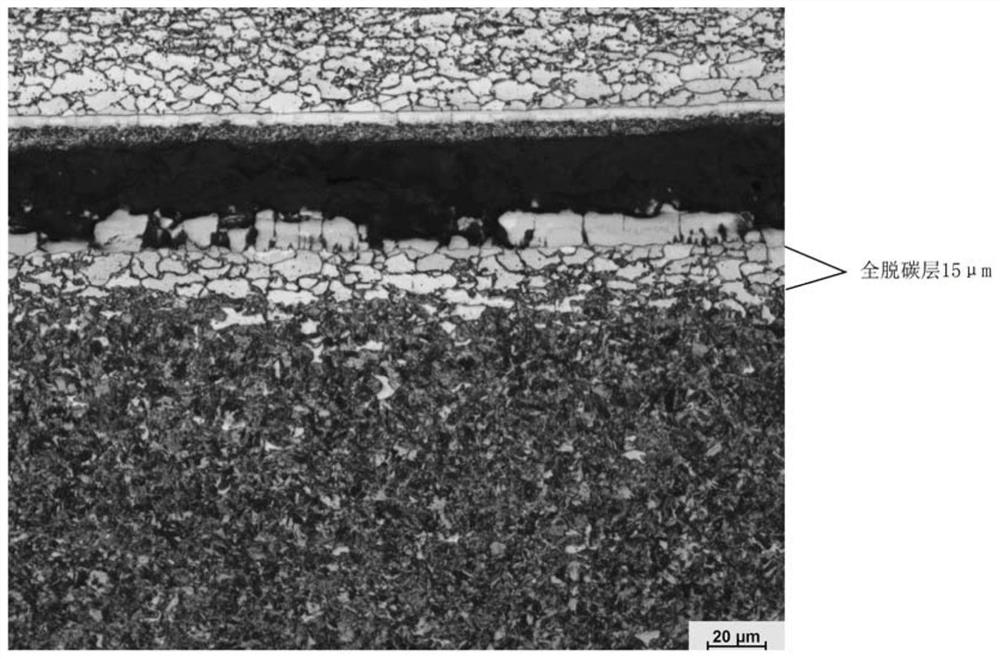

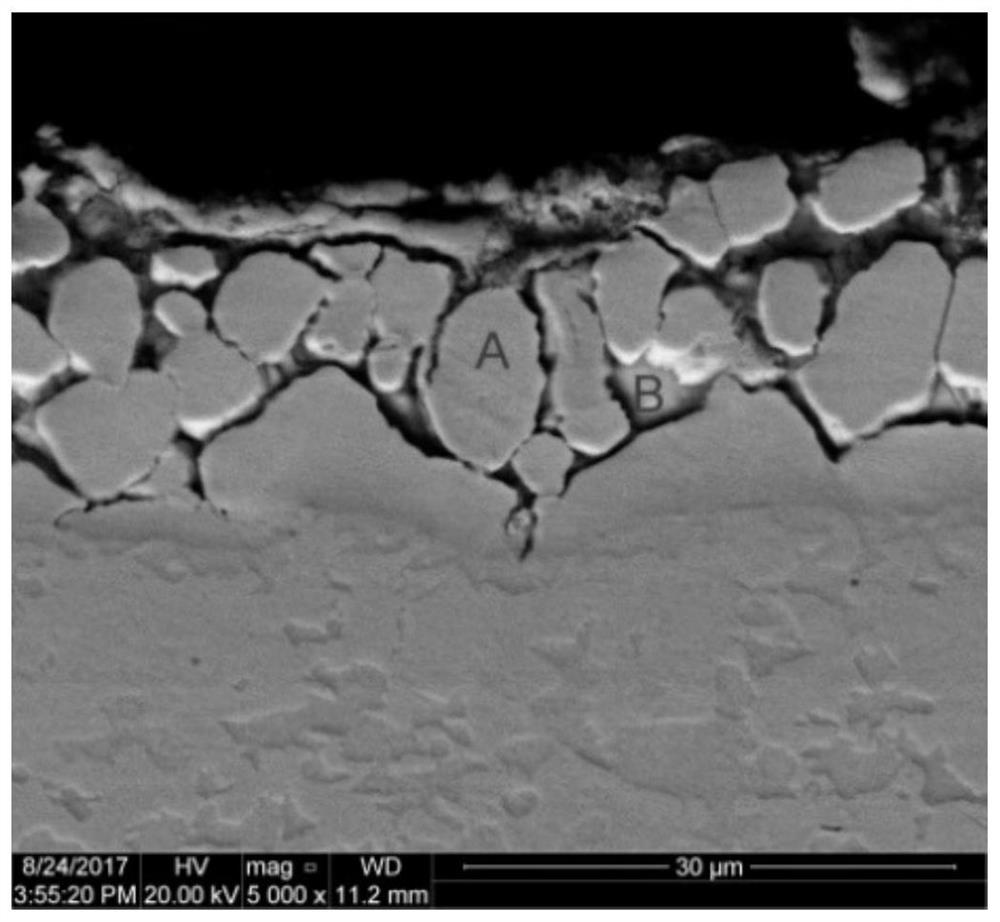

[0067] The microstructures of the thermoformed member containing the zinc coating layer obtained in Example 3 before and after thermoforming are respectively as follows: figure 1 , 2 As shown in Figures 1 and 2, it can be seen that the thickness of the decarburized layer of the steel strip after annealing is 25 μm, and the thickness of the decarburized layer after hot forming is 15 μm. ≈25%.

[0068] The polarization curve of the thermoformed member containing the zinc coating layer obtained in Example 3, the thermoformed member containing the Al-Si coating in Comparative Example 1, and the thermoformed member without the coating plate are as follows Figure 4 As shown, it can be seen from the figure that the electrode potential of the Zn-containing coating is lower than that of the substrate and the Al-Si coating. Therefore, it has a sacrificial anode protection effect in a corrosive environment, thereby improving corrosion resistance.

[0069] The corrosion performance and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com