17-4PH stainless steel and structure and performance regulation and control method thereof

A technology of stainless steel and structure, which is applied in the field of stainless steel, can solve the problems that cannot be achieved at the same time, and achieve the effect of improving intergranular corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

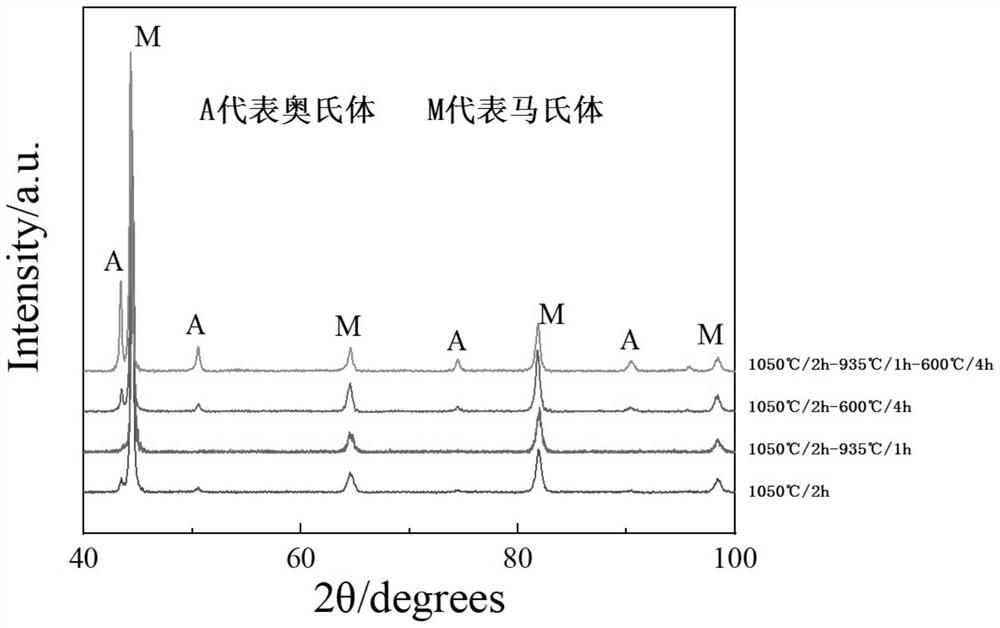

[0029] A 17-4PH stainless steel, the chemical composition (wt%) is: C: 0.04, Si: 0.3, Mn: 0.8, S: 0.002, P: 0.01, Cr: 15.6, Ni: 4.5, Mo: 0.2, Cu: 3.5 , Nb: 0.5, N: 100PPM, wherein, the molar ratio of Nb and C is: n Nb / n C = 1.63.

[0030] A microstructure and performance control method for 17-4PH stainless steel. The stainless steel workpiece is heated to 1050°C for 2 hours, water cooled to room temperature, and the cooling rate is 150°C / S; the stainless steel workpiece is reheated to 935°C for 0.5h, and oil-cooled. To room temperature, the cooling rate is 220°C / S; finally carry out aging treatment at 520°C for 4h.

[0031] After testing, the final obtained 17-4PH stainless steel workpiece has a hardness of 38.2HRC and a low temperature impact energy of -46°C of 28J. The intergranular corrosion resistance adopts the double-loop potentiodynamic reactivation method (DL-EPR), Ir / Ia=0.39, which meets the technical requirements of the workpiece.

Embodiment 2

[0033] A 17-4PH stainless steel, the chemical composition (wt%) is: C: 0.04, Si: 0.3, Mn: 0.8, S: 0.002, P: 0.01, Cr: 15.6, Ni: 4.5, Mo: 0.2, Cu: 3.5 , Nb: 0.5, N: 100PPM, wherein, the molar ratio of Nb and C is: n Nb / n C = 1.63.

[0034] A microstructure and performance control method for 17-4PH stainless steel. The stainless steel workpiece is heated to 1050°C for 2 hours, cooled to room temperature with water at a cooling rate of 150°C / S; then the sample is reheated to 935°C for 1 hour, and oil cooled to At room temperature, the cooling rate is 220°C / S; finally, the aging treatment is carried out at 520°C for 4 hours.

[0035] After testing, the hardness of the finally obtained 17-4PH stainless steel workpiece is 37.6HRC; the low temperature impact energy at -46°C is 31J. The intergranular corrosion resistance adopts the double-loop potentiodynamic reactivation method (DL-EPR), Ir / Ia=0.35, which meets the technical requirements of the workpiece.

Embodiment 3

[0037] A 17-4PH stainless steel, the chemical composition (wt%) is: C: 0.04, Si: 0.3, Mn: 0.8, S: 0.002, P: 0.01, Cr: 15.6, Ni: 4.5, Mo: 0.2, Cu: 3.5 , Nb: 0.45, N: 80PPM. Wherein, the molar ratio of Nb and C is: n Nb / n C = 1.47.

[0038] A microstructure and performance control method for 17-4PH stainless steel. The stainless steel workpiece is heated to 1050°C for 2 hours, cooled to room temperature with water at a cooling rate of 300°C / S; then the sample is reheated to 950°C for 0.5h, oil cooled To room temperature, the cooling rate is 100°C / S; finally, aging treatment is carried out at 520°C for 4 hours.

[0039] After testing, the final 17-4PH stainless steel workpiece has a hardness of 38.4HRC and a low-temperature impact energy of -46°C of 30J. The intergranular corrosion resistance adopts the double-loop potentiodynamic reactivation method (DL-EPR), Ir / Ia=0.37, which meets the technical requirements of the workpiece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Low temperature impact energy | aaaaa | aaaaa |

| Low temperature impact energy | aaaaa | aaaaa |

| Low temperature impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com