Online sampling and verifying gas density relay with protection function

A technology of density relay and gas density, applied in the field of electric power, can solve problems such as flashover, hazards, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

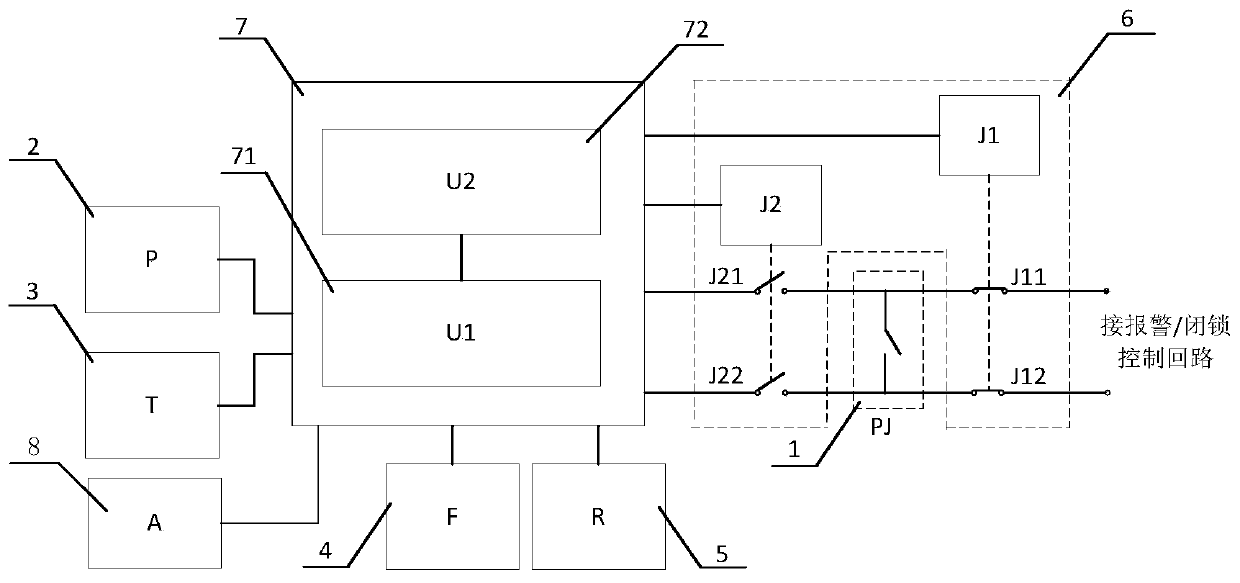

[0178] figure 1 It is a schematic diagram of a control circuit of an on-line sampling and verification gas density relay with protection function of the high-voltage electrical equipment in Embodiment 1 of the present invention. Such as figure 1 As shown, an on-line sampling and verification gas density relay with protection function includes: gas density relay body 1, pressure sensor 2, temperature sensor 3, valve 4, temperature adjustment mechanism 5, on-line verification contact signal sampling unit 6, Intelligent control unit 7 and pressure regulating mechanism 8. One end of the valve 4 is provided with an interface connected with electrical equipment, and the other end of the valve 4 is connected with the gas density relay body 1; the temperature adjustment mechanism 5 is arranged opposite to the gas density relay 1, and the temperature sensor 3 is arranged in the housing of the density relay 1 . Specifically, the temperature adjusting mechanism 5 is arranged outside t...

Embodiment 2

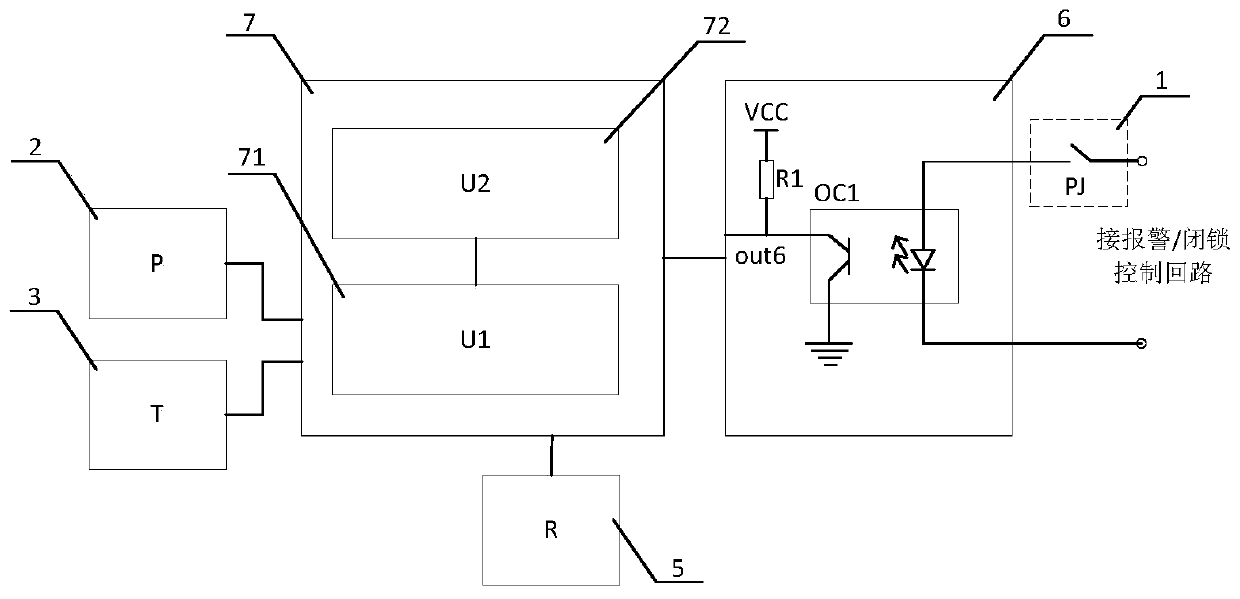

[0188] Such as figure 2 As shown, the online verification contact signal sampling unit 6 is provided with a contact sampling circuit. In this embodiment, the contact sampling circuit includes a photocoupler OC1 and a resistor R1, the photocoupler OC1 includes a light emitting diode and a phototransistor; the anode of the light emitting diode and the gas density relay body 1 Contact P J Form a closed loop in series; the emitter of the phototransistor is grounded; the collector of the phototransistor is connected to the intelligent control unit 7 as the output terminal out6 of the online verification contact signal sampling unit 6, and the collection of the phototransistor The electrodes are also connected to the power supply through the resistor R1.

[0189] Through the above contact sampling circuit, it is convenient to know the contact P of the gas density relay body 1 J is open or closed. Specifically, when the joint P J When closed, the closed circuit is energized, th...

Embodiment 3

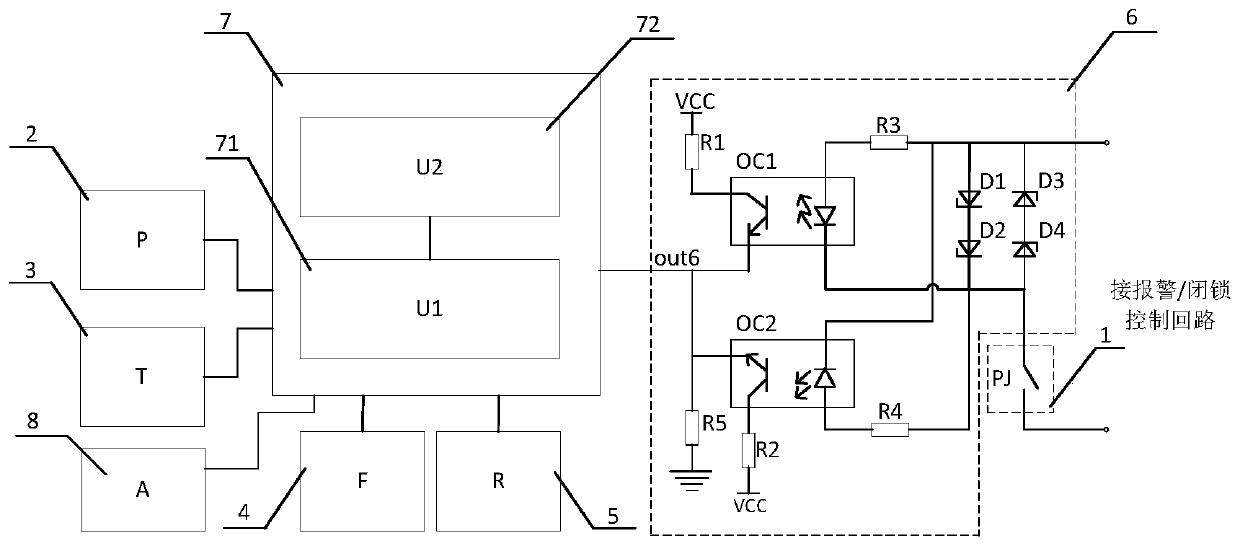

[0193] Such as image 3 As shown, the online verification contact signal sampling unit 6 is provided with a contact sampling circuit. In this embodiment, the contact sampling circuit includes a first optocoupler OC1 and a second optocoupler OC2.

[0194] The light-emitting diodes of the first photocoupler OC1 and the light-emitting diodes of the second photocoupler OC2 are respectively connected in parallel through current-limiting resistors, and after being connected in parallel, they are connected in series with the contacts of the gas density relay body to form a closed loop, and the first The connection direction of the light-emitting diode of a photocoupler OC1 and the second photocoupler OC2 is opposite; the collector of the phototransistor of the first photocoupler OC1 and the collector of the phototransistor of the second photocoupler OC2 The electrodes are all connected to the power supply through a voltage dividing resistor, and the emitter of the phototransistor of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com