Judgment method of aging degree of composite insulator

A technology of composite insulators and aging degree, applied in the direction of strength characteristics, using stable tension/pressure test material strength, short circuit test, etc., can solve the problems of expensive equipment and high cost, and achieve low cost, high accuracy, good aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

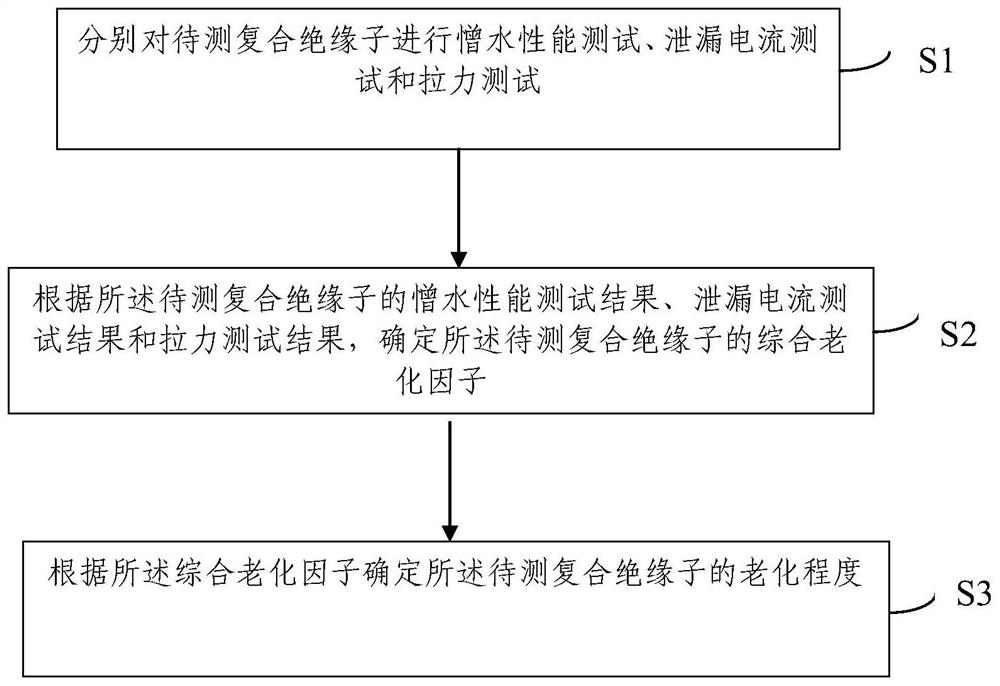

[0039] see figure 1 , a method for judging the aging degree of a composite insulator, the method comprising the following steps:

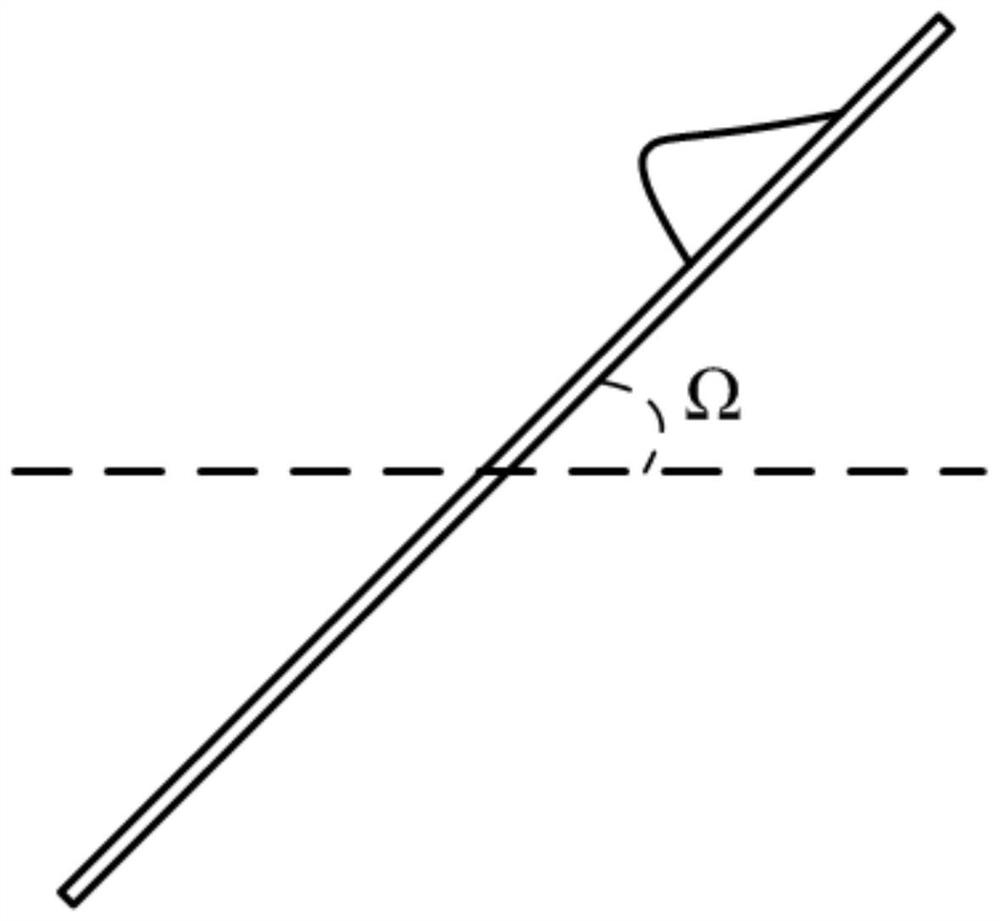

[0040] S1. Reference figure 2 The schematic diagram of the hydrophobic angle measurement of , the experimental steps are: ① Cut the composite insulator material into 5cm*5cm*2cm slices. ② Place the test sample in NaCl solution doped with 30% mass, and boil the solution for 100h. ③Wipe the sample clean and dry it, place the water drop on the surface of the material, slice and tilt the composite insulator, measure the angle Ω between the inclined surface and the horizontal plane when the water drop just does not slip, and compare the material sample with the unaged Composite insulator tilt angle Ω N In contrast, the oblique angle aging factor α=Ω / Ω is obtained N ;

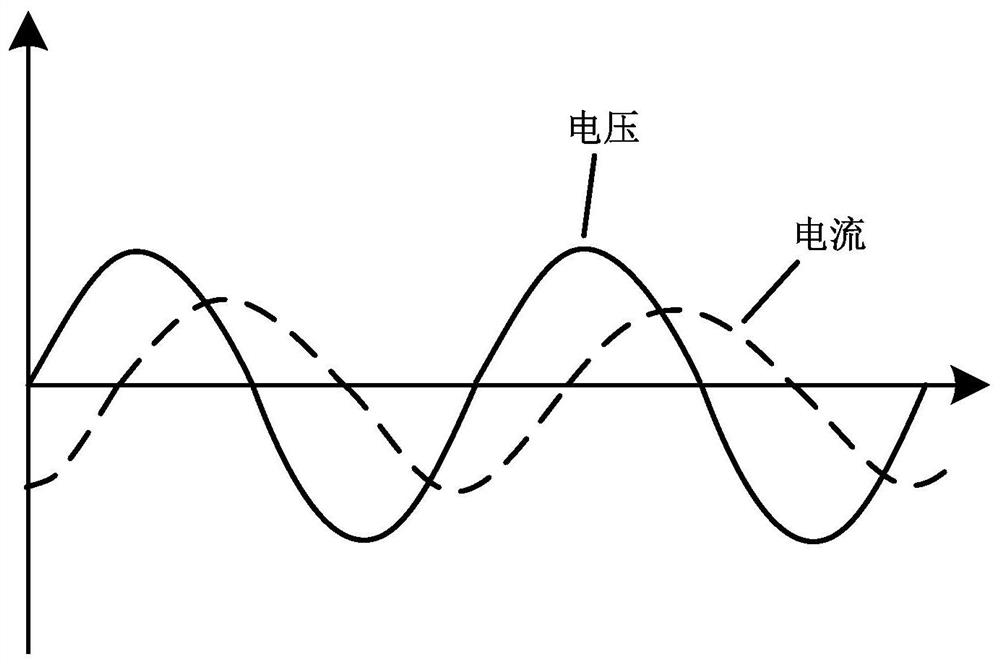

[0041] Such as figure 2 The diagram of the applied voltage and leakage current of the composite insulator is shown, and the experimental steps are as follows: ① The test transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com