Adhesion improver for carbon-fiber-reinforced resin composition

A technology of resin composition and imparting agent, applied in the direction of adhesive type, epoxy glue, adhesive, etc., can solve the problems of lack of strength and rigidity, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

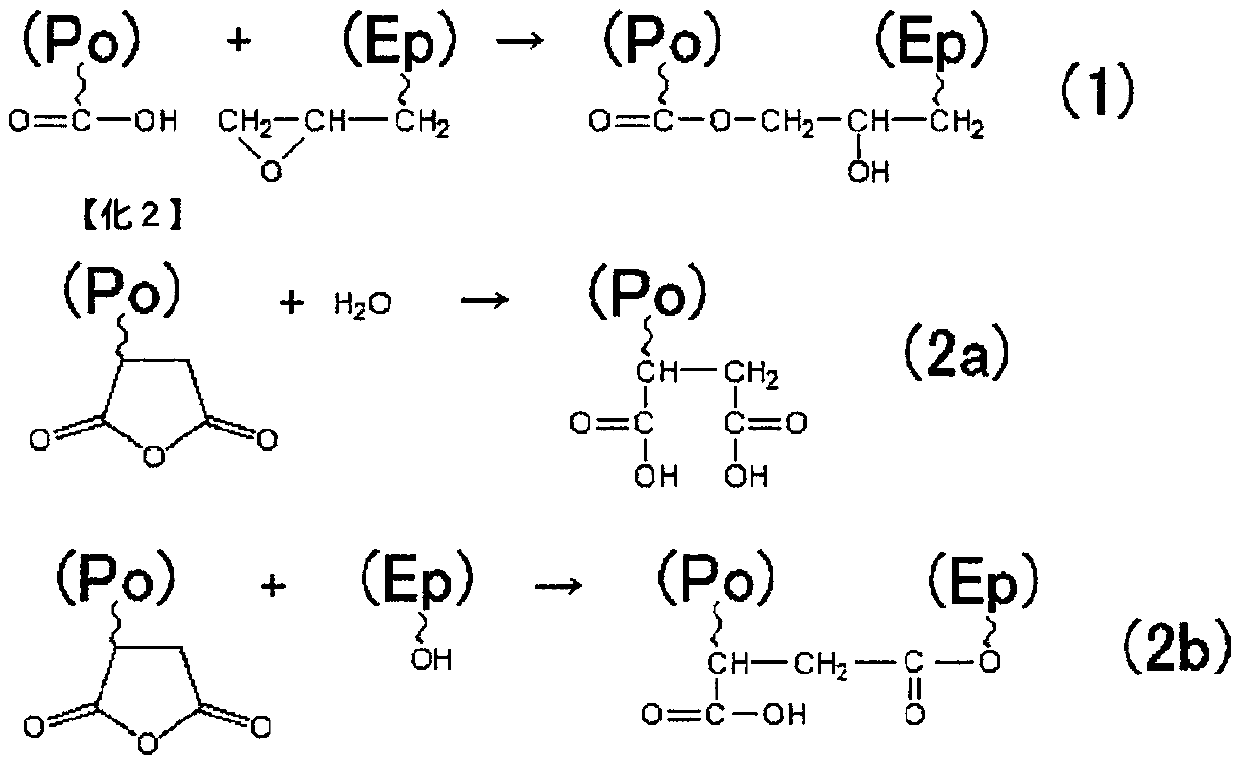

Method used

Image

Examples

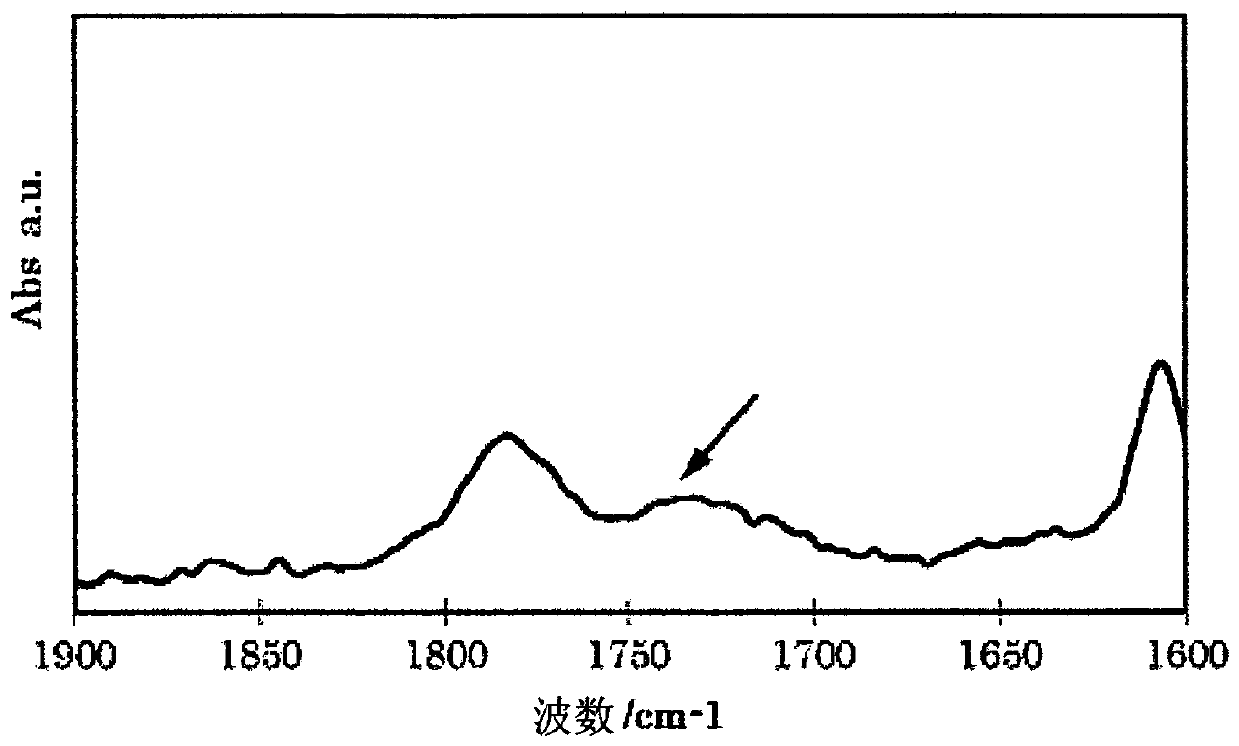

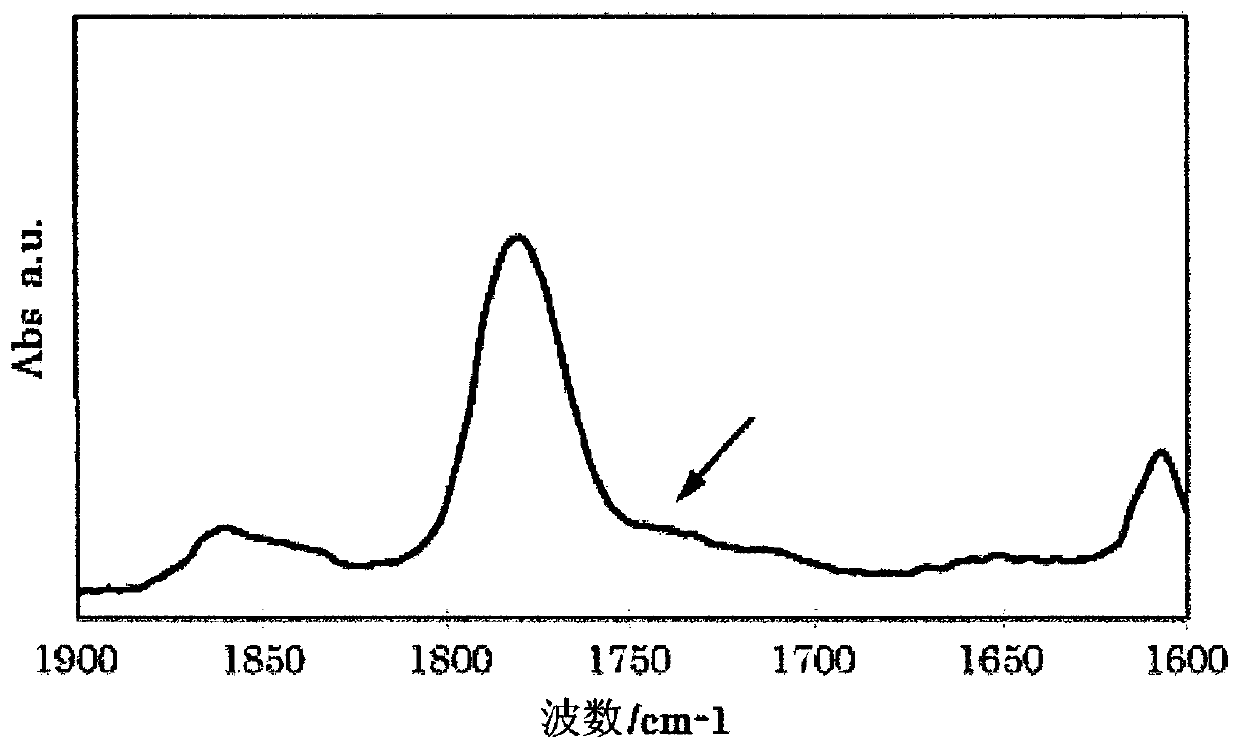

Embodiment 1

[0150] 90 parts of d-1 as an acid-modified polyolefin resin, 10 parts of d-1 as After e-1 of the epoxy resin, preheat and melt for 1 minute. Then, 1 part of f-1 was added as a catalyst, and it heated and melt-mixed at 170 degreeC for 6 minutes. After completion of melt-mixing, it was taken out of the system and left to cool to obtain an adhesiveness-imparting agent (C-1). Table 2 shows the results of measuring the presence or absence of IR absorption due to the ester bond and the melt viscosity of the obtained adhesiveness imparting agent.

Embodiment 2~5、13~19

[0151] Embodiment 2~5, 13~19, reference example 1, 2

[0152] Acid-modified polyolefin resins d-1 to 3, epoxy resins e-1 to 5, and catalyst f-1 were mixed in proportions (parts) described in Table 2A and Table 2B, using the same device as in Example 1 , Adhesiveness imparting agents (C-2 to 12, SC-1, 2) were obtained by the same operation. Table 2 shows the results of measuring the presence or absence of IR absorption due to the ester bond and the melt viscosity of the obtained adhesiveness imparting agent. In addition, the molar ratio in a table|surface represents the molar ratio (AE / EE) of the carboxyl group (AE) of an acid-modified polyolefin resin, and the epoxy group (EE) of an epoxy resin.

[0153] [Table 2A]

[0154] Example 1 2 3 4 5 Reference 1 Reference 2 d-1 90 90 d-2 50 50 d-3 50 50 70 e-1 10 50 50 50 30 10 50 f-1 1 1 1 0.1 1 The molar ratio of 3.9 30.0 38.0 38.0 8...

Embodiment 6

[0158] 10 parts of the adhesion-imparting agent (C-1) obtained in Example 1 and 90 parts of B as a polyolefin resin were put into a kneading extrusion molding machine in which the inside of the mixer was preheated to 200°C. After -1, preheating and melting were performed for 1 minute, and heating and melting and mixing were further performed at 200° C. for 3 minutes. After completion of the melt mixing, it was taken out of the system and left to cool to obtain a resin composition 6 composed of an adhesiveness imparting agent and a polyolefin-based resin. The interfacial shear strength of the obtained resin composition 6 was measured, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com