Crankshaft neck surface waviness grinding tool and using method thereof

A surface waviness and crankshaft journal technology, which is applied in the field of crankshaft journal surface waviness grinding tools, can solve the problems of affecting the service life of the engine, engine performance degradation, and waviness out of tolerance, so as to achieve low cost of use and avoid unnecessary loss, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

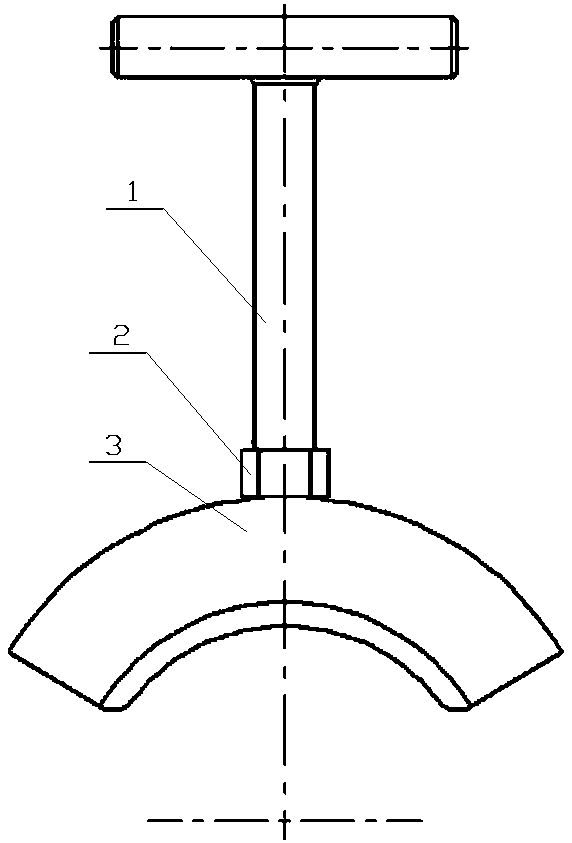

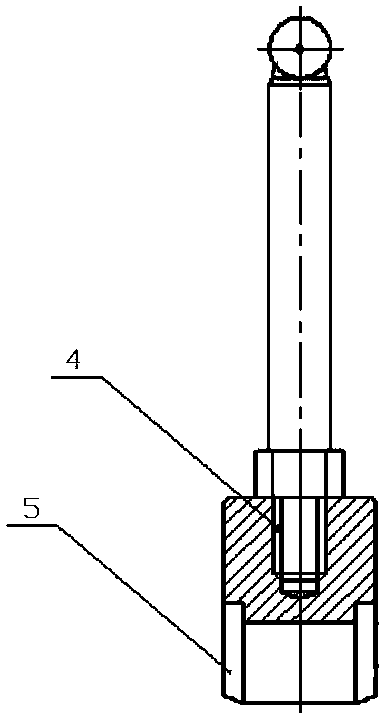

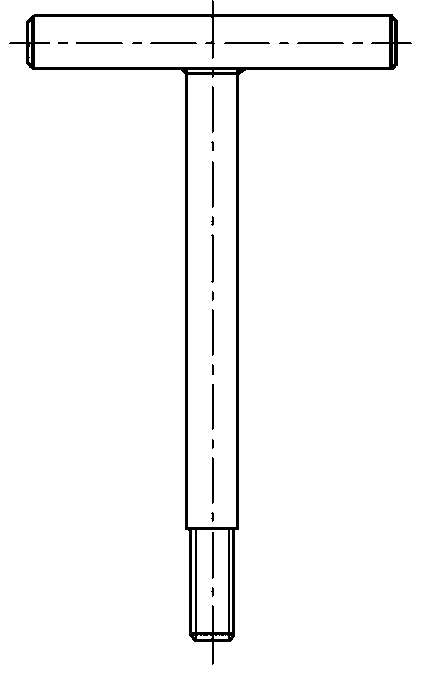

[0025] Such as Figure 1-5 As shown, a crankshaft journal surface waviness grinding tool is mainly composed of a handle 1, a lock nut 2 and a grinding body 3; the grinding body 3 is 1 / 3 arc long and its width is smaller than the length of the ground journal 0.1mm fan-shaped ring; a threaded hole 4 is provided at the top middle of the grinding body 3, and the arc surface at the bottom of the grinding body 3 is the grinding working surface, and the two sides are respectively provided with relief grooves 5; The lower end of the handle 1 is provided with an external thread, and the size of the external thread matches the threaded hole 4 of the grinding body 3; the lock nut 2 matches the external thread of the handle 1; the lower end of the handle 1 passes through the After locking the nut 2, it is fixed together with the threaded hole 4 of the grinding body 3 by threaded connection. The handle 1 is a T-shaped handle. The transverse bar of the T-shaped handle is a round bar with ...

Embodiment 2

[0027] A crankshaft journal surface waviness grinding tool, mainly composed of a handle 1, a lock nut 2 and a grinding body 3; the grinding body 3 is 1 / 2 arc long and 0.1mm smaller in width than the length of the ground journal Fan-shaped ring; a threaded hole 4 is provided at the top middle of the grinding body 3, and the arc surface at the bottom of the grinding body 3 is a grinding working surface, and both sides are respectively provided with relief grooves 5; the handle 1 The lower end is provided with an external thread, and the size of the external thread matches the threaded hole 4 of the grinding body 3; the lock nut 2 matches the external thread of the handle 1; the lower end of the handle 1 passes through the lock nut After 2, it is fixed together with the threaded hole 4 of the grinding body 3 by threaded connection. The difference between the inner diameter of the grinding body 3 and the diameter of the journal to be ground is within about 0.01 mm, and the smoothn...

Embodiment 3

[0029] A crankshaft journal surface waviness grinding tool, mainly composed of a handle 1, a lock nut 2 and a grinding body 3; the grinding body 3 is 1 / 2 arc long and 0.1mm smaller in width than the length of the ground journal Fan-shaped ring; a threaded hole 4 is provided at the top middle of the grinding body 3, and the arc surface at the bottom of the grinding body 3 is a grinding working surface, and both sides are respectively provided with relief grooves 5; the handle 1 The lower end is provided with an external thread, and the size of the external thread matches the threaded hole 4 of the grinding body 3; the lock nut 2 matches the external thread of the handle 1; the lower end of the handle 1 passes through the lock nut After 2, it is fixed together with the threaded hole 4 of the grinding body 3 by threaded connection. The difference between the inner diameter of the grinding body 3 and the diameter of the journal to be ground is within 0.02 mm, and the smoothness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com