Linkage supply-type rail spike conveying equipment

A technology of conveying equipment and spikes, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., which can solve the problems of material jams and chaotic feeding of spikes, so as to reduce the phenomenon of material jams and ensure the production rhythm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

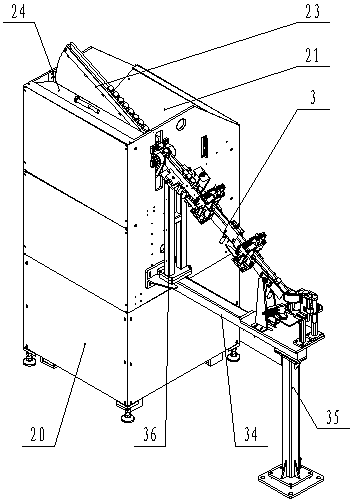

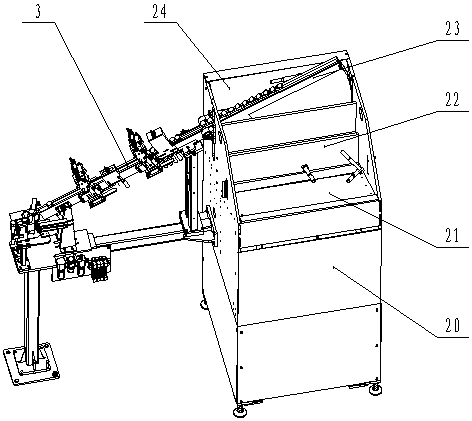

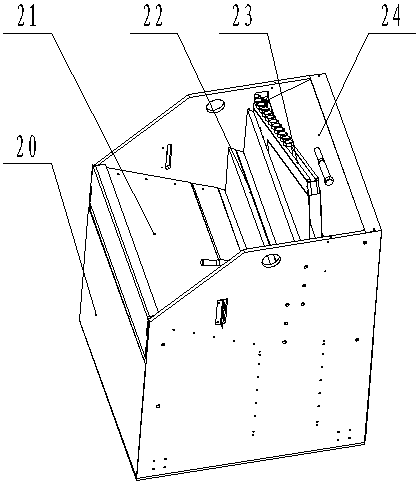

[0059] Such as Figure 1 to Figure 12 As shown, a linkage supply type spike conveying equipment in this embodiment includes a spike feeder line 1, a stepped feeder 2 and a discharge mechanism 3, and the spike feeder line 1 is used to convey the spike to Step feeder 2, the step feeder 2 sends the spikes to the discharge mechanism 3 in a step feed manner.

[0060] In this embodiment, the road stud feeding line 1 is a chain plate feeding line, and the road stud blanks are manually poured into the chain plate feeding line; the chain plate feeding line performs linkage replenishment according to the amount of material in the ladder feeder. Linkage replenishment can be realized by setting a weighing sensor at the feeding trough 21, the weighing sensor transmits the detection signal to the signal input terminal of the central control processor, and the signal output terminal of the central control processor is connected to the spike feeding line 1. It can also be realized by other r...

Embodiment 2

[0083] Such as Figure 13 to Figure 14 As shown, this embodiment also discloses an automatic production line for road studs, which includes linkage replenishment type spike conveying equipment, a spike heating machine 5 and a road spike thread rolling machine 6, wherein the linkage replenishment type spike conveying equipment refers to Embodiment 1 .

[0084] Among them, the spike heating machine 5 is set at the end of the linkage supply type spike conveying equipment, which includes a turntable feeding mechanism and a heating mechanism 52. The turntable feeding mechanism includes a chain ring 511 arranged horizontally, and the chain ring 511 is connected with a drive to drive it to rotate. The chain ring transmission mechanism 512, the outer side of the chain ring 511 is arranged in a circumferential arrangement with outwardly protruding road spike supporting parts 513, and the road nail supporting parts 513 are provided with supporting card slots 514 for supporting road spik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com