A kind of cefuroxime sodium raw material and injection and preparation method thereof

A technology of cefuroxime sodium and cefuroxime acid, which is applied in the field of medicine and can solve problems such as rapid growth and poor control of related substances 2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

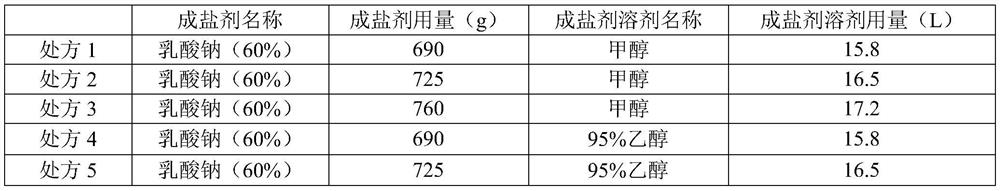

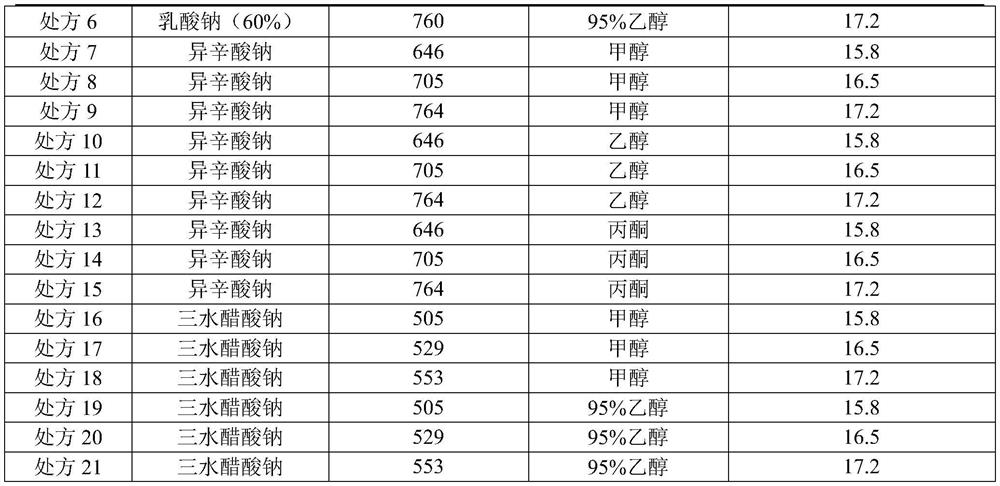

[0039] Embodiment 1 prepares cefuroxime sodium raw material of the present invention

[0040] (1) Preparation of cefuroxime acid solution: add methanol (50L), dehydrated ethanol (98L) and water (2L) respectively in a clean stainless steel batching tank A, stir and control the liquid temperature in the stainless steel tank A to 10 -15°C, then add cefuroxime acid (15kg) weighed in advance, control the temperature at 10-15°C and completely dissolve to obtain a cefuroxime acid solution, and set aside;

[0041] (2) Preparation of salt-forming agent solution: Measure and add 95% ethanol (150L) into the clean stainless steel batching tank B, stir and control the liquid temperature in the stainless steel tank B to 10-15°C, and then add the mixture that has been weighed in advance Sodium acetate trihydrate (5.29kg), temperature control 10-15 ℃ and after dissolving completely, obtain salt-forming agent solution, standby;

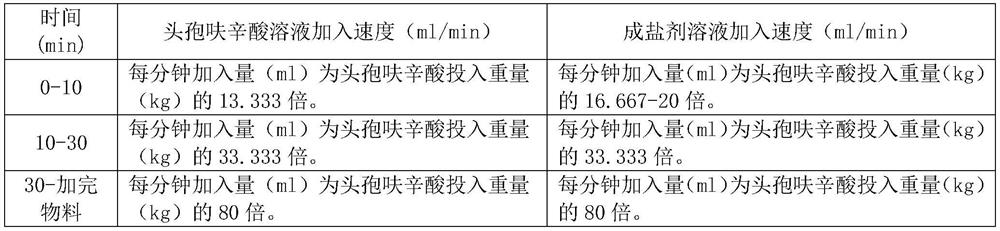

[0042] (3) Salt-forming reaction: Methanol (10L), absolute etha...

Embodiment 2

[0044] Embodiment 2 prepares cefuroxime sodium raw material of the present invention

[0045] (1) Preparation of cefuroxime acid solution: add methanol (55L), absolute ethanol (108L) and water (2L) into a clean stainless steel batching tank respectively, stir and control the liquid temperature in the stainless steel tank to 10-15 ℃, then add cefuroxime acid (15kg) weighed in advance, after temperature control 10-15 ℃ and completely dissolved, cefuroxime acid solution is obtained for subsequent use;

[0046] (2) Preparation of salt-forming agent solution: Measure and add 95% ethanol (165L) respectively in a clean stainless steel batching tank, stir and control the liquid temperature in the stainless steel tank to 10-15°C, then add the pre-weighed three Water sodium acetate (5.29kg), temperature control 10-15 ℃ and after completely dissolving, obtain salt-forming agent solution, standby;

[0047] (3) Salt-forming reaction: Methanol (11L), absolute ethanol (21.6L), water (0.4L),...

Embodiment 3

[0049] Embodiment 3 prepares cefuroxime sodium raw material of the present invention

[0050] (1) Preparation of cefuroxime acid solution: Methanol (60L), dehydrated ethanol (118L) and water (2L) were metered into clean stainless steel batching tank A respectively, stirred and the liquid temperature in stainless steel tank A was controlled to 10 -15°C, then add cefuroxime acid (15kg) weighed in advance, control the temperature at 10-15°C and completely dissolve to obtain a cefuroxime acid solution, and set aside;

[0051] (2) Preparation of salt-forming agent solution: Measure and add 95% ethanol (180L) into the clean stainless steel batching tank B respectively, stir and control the liquid temperature in the stainless steel tank B to 10-15°C, then add the Sodium acetate trihydrate (5.29kg), temperature control 10-15 ℃ and after dissolving completely, obtain salt-forming agent solution, standby;

[0052] (3), salt-forming reaction: Methanol (12L), absolute ethanol (23.6L), wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com