A hydrogenation mixture preparation process

A mixture and process technology, applied in the field of hydrogenation mixture preparation process, can solve the problems of effect gap and conversion rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Distill or extract the heavy oil, dry and remove water, crush, grind, and deash the pulverized coal to make it meet the indicators in Table 1 and Table 2 below, and then mix it with the circulating oil in Table 3 and add it to the following table The hydrogenation reaction was carried out under the indicated parameters.

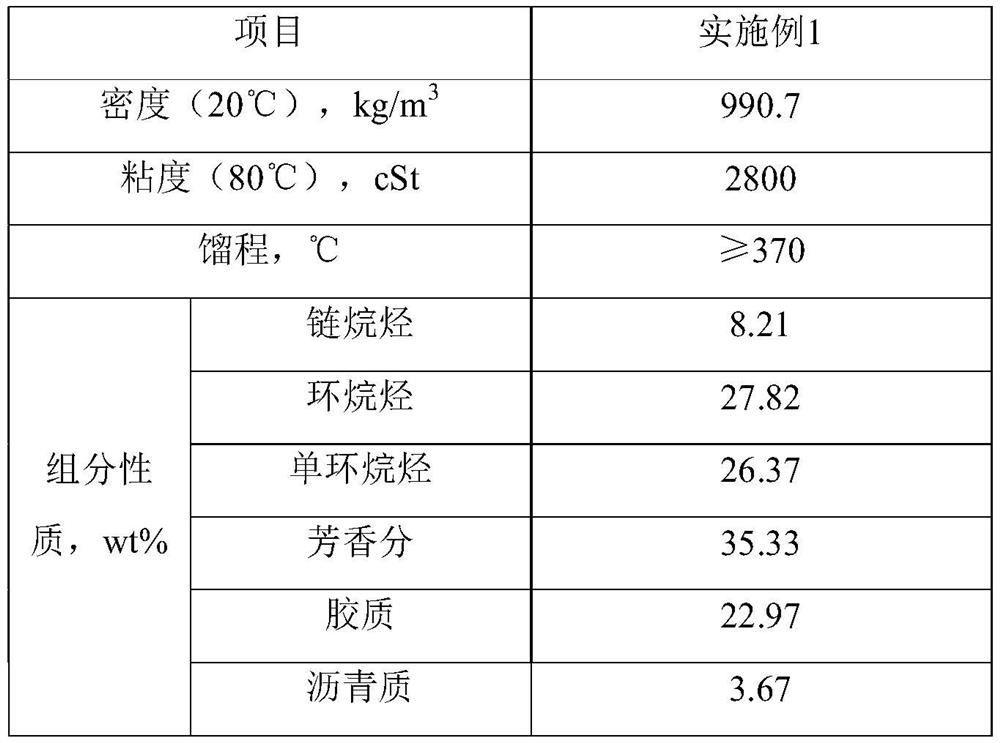

[0031] Table 1 Basic properties of heavy oil

[0032]

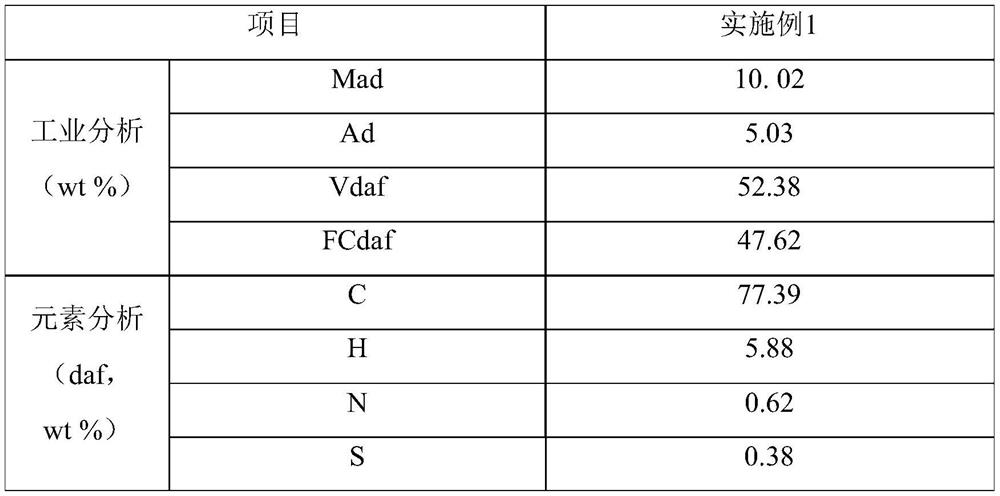

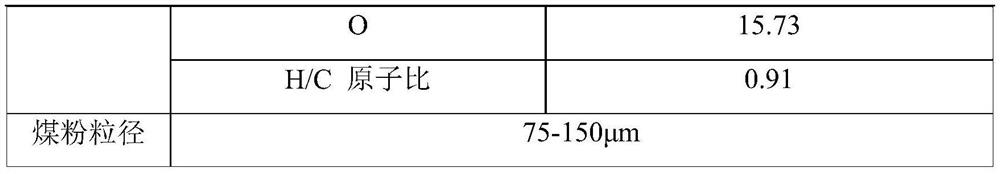

[0033] Table 2 Basic Properties of Pulverized Coal

[0034]

[0035]

[0036] Table 3 Basic properties of circulating oil

[0037]

[0038] Table 4 Basic Properties of Mixtures

[0039] project Example 1 Ratio of oil and coal wt / wt 45:55 density 20℃,kg / m 3

1140.1 Ash % 2.31 viscosity 20°C, cSt 980.77

[0040] Table 5 hydrogenation reaction operating parameter list

[0041] project value Raw material composition Heavy oil: circulating oil: pulverized coal=0.86:0.37:1 Catalyst amount (active metal amount), ppm...

Embodiment 2-4

[0045] The properties of the material are as follows:

[0046] Table 7 Example 2-4 heavy oil basic properties table

[0047]

[0048] Table 8 Example 2-4 Pulverized coal basic properties table

[0049]

[0050] Table 9 embodiment 2-4 hydrogenation reaction operation parameter list

[0051] Raw material composition Example 2 Example 3 Example 4 Heavy Oil: Cycle Oil: Coal Powder 0.81:0.39:1 0.84:0.36:1 0.88:0.32:1

[0052] Other reaction condition parameters and batching properties are the same or close to those of Example 1, and the circulating oil viscosity is all lower than 100cSt (80°C).

[0053] Table 10 embodiment 2-4 reaction result data table

[0054] project Example 2 Example 3 Example 4 Pulverized coal conversion rate, wt% 99.12 99.23 99.42 Gas yield, wt% 8.73 9.65 8.92 ≤370℃ distillate oil yield 75.15 77.23 75.37

[0055] in conclusion:

[0056] As can be seen from the above examples, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com