Preparation method of solid color enhancement sheet

A solid, color enhancer technology, applied in dyeing, textile and paper making, etc., can solve the problems of poor use effect, troublesome, fading and darkening, etc., and achieve the effect of light weight, convenient use and easy grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

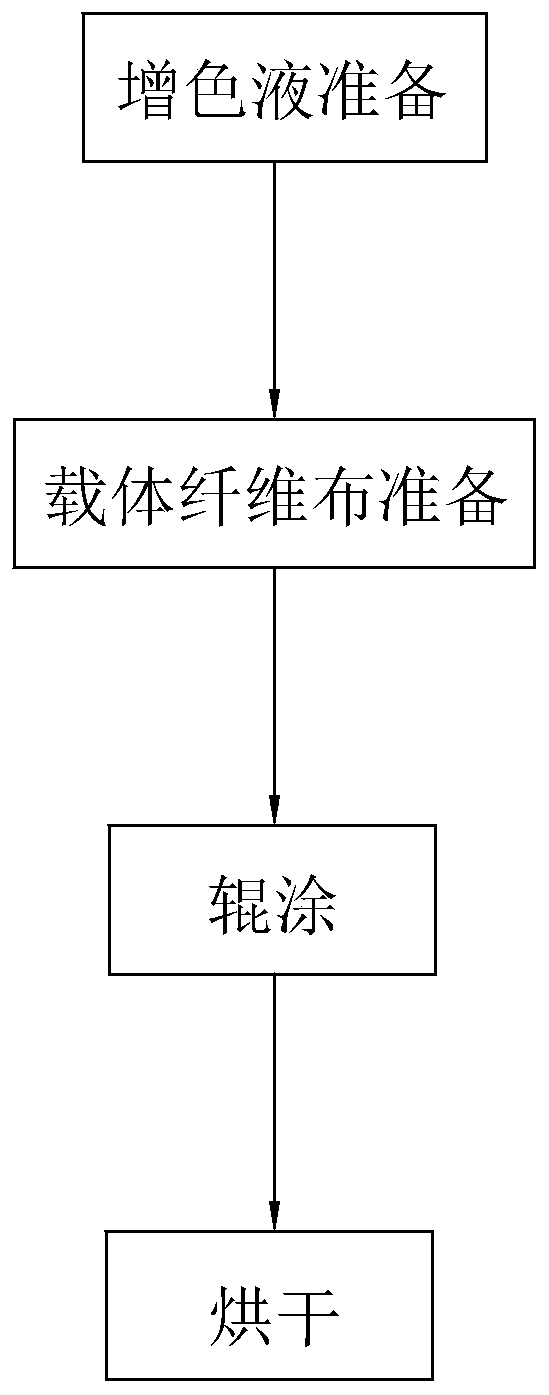

[0037] Embodiment 1: A solid color-enhancing tablet, prepared through the following steps:

[0038] Step 1, preparation of coloring solution: Dissolve 12 parts of cationic silicone polymer and 5 parts of acrylic resin in deionized water, adjust pH=7, add 1 part of Gemini surfactant and 8 parts of rare earth compound, stir and mix evenly, get the color enhancer;

[0039] Step 2, preparation of carrier fiber cloth: 45 parts of polyamide fiber raw materials are opened, carded into a net and spunlace to obtain a carrier fiber cloth with a thickness of 0.6 mm;

[0040] Step 3, roller coating: roll-coat the color enhancing liquid onto one side of the carrier fiber cloth by roller coating;

[0041] Step 4, drying: drying the carrier fiber cloth at a temperature of 100°C to obtain a solid color-increasing sheet;

[0042] In this example, the cationic organosilicon polymer uses VIvo brand deepening agent produced by P&G Company of the United States; the Gemini surfactant adopts the s...

Embodiment 2-6

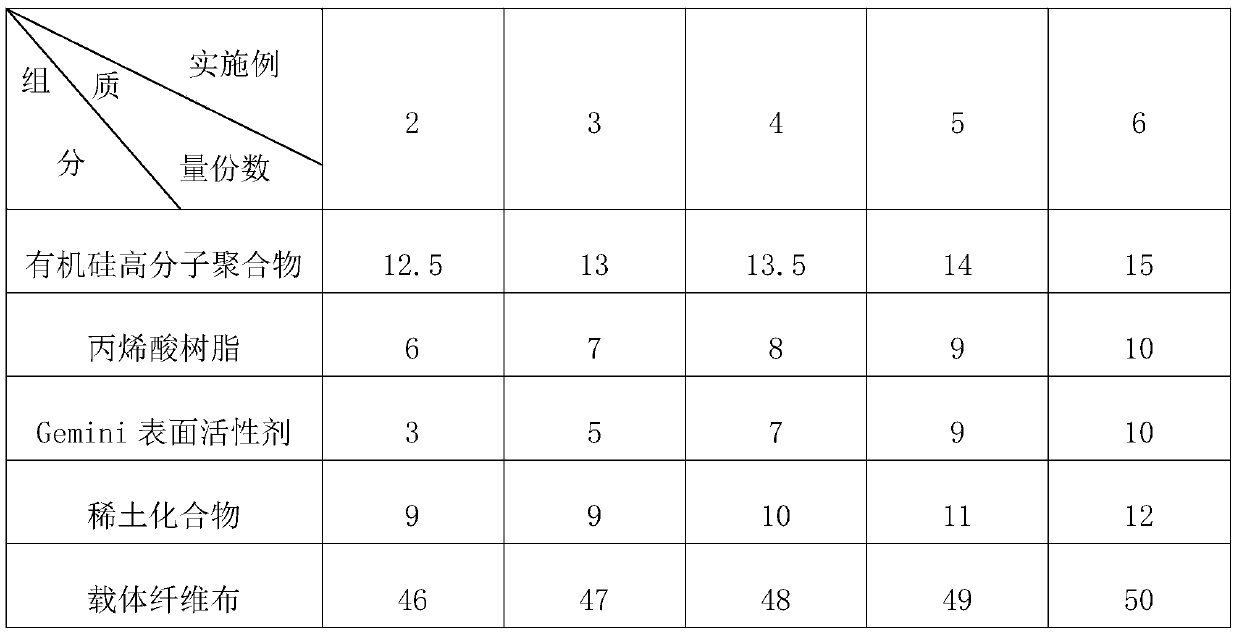

[0043] Embodiment 2-6: A solid color enhancement sheet, the difference from Embodiment 1 is that each component and its corresponding parts by mass are shown in Table 1.

[0044] Each component and its mass parts in table 1 embodiment 2-6

[0045]

Embodiment 7

[0046] Embodiment 7: A solid color-enhancing sheet, prepared through the following steps:

[0047] Step 1, preparation of color enhancement solution: dissolve 12 parts of black dye and 5 parts of acrylic resin in deionized water, adjust pH=7, add 1 part of Gemini surfactant and 8 parts of rare earth compound, stir and mix evenly to obtain color enhancement solution;

[0048] Step 2, preparation of carrier fiber cloth: 45 parts of polyamide fiber raw materials are opened, carded into a net and spunlace to obtain a carrier fiber cloth with a thickness of 0.6 mm;

[0049] Step 3, roller coating: roll-coat the color enhancing liquid onto one side of the carrier fiber cloth by roller coating;

[0050] Step 4, drying: drying the carrier fiber cloth at a temperature of 100°C to obtain a solid color-increasing sheet;

[0051] In this embodiment, the black dye is an azo dye produced by Leon Dye Firm in Longgang District, Shenzhen; the Gemini surfactant is a surfactant produced by Jini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com