A method for evaluating the release of phosphine from a phosphorus-based flame retardant and its application

A phosphorus-based flame retardant and evaluation method technology, which is applied in the field of material chemical analysis and detection, can solve problems such as difficult detection, and achieve the effects of fast detection, optimized processing technology, and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 detects phosphine release in open system (method 1)

[0057] (1) Take 3g of red phosphorus flame retardant powder and put it into a glass petri dish without a cover, immerse half of a 30mm×5mm×1.5mm pure copper sheet in the powder, and fully contact with the air. Set the constant temperature and humidity chamber parameters as 23°C, 50RH% and 40°C, 70RH% respectively;

[0058] (2) After 14, 21, and 28 days, take out the corroded copper sheet with tweezers, transfer it into a 50mL beaker filled with 10mL 3.65wt% dilute hydrochloric acid, seal the bottle mouth with plastic wrap, and let it stand for 48 hours;

[0059] (3) Take out the copper sheet, transfer the solution containing the corrosion product to a 10mL reagent bottle, and measure the content of phosphorus element with an inductively coupled plasma emission spectrometer. The results are shown in Table 1.

[0060] Table 1 The quality of phosphorus in flame retardants measured by inductively coupled pl...

Embodiment 2

[0062] Embodiment 2 detects phosphine release in closed system (method 2)

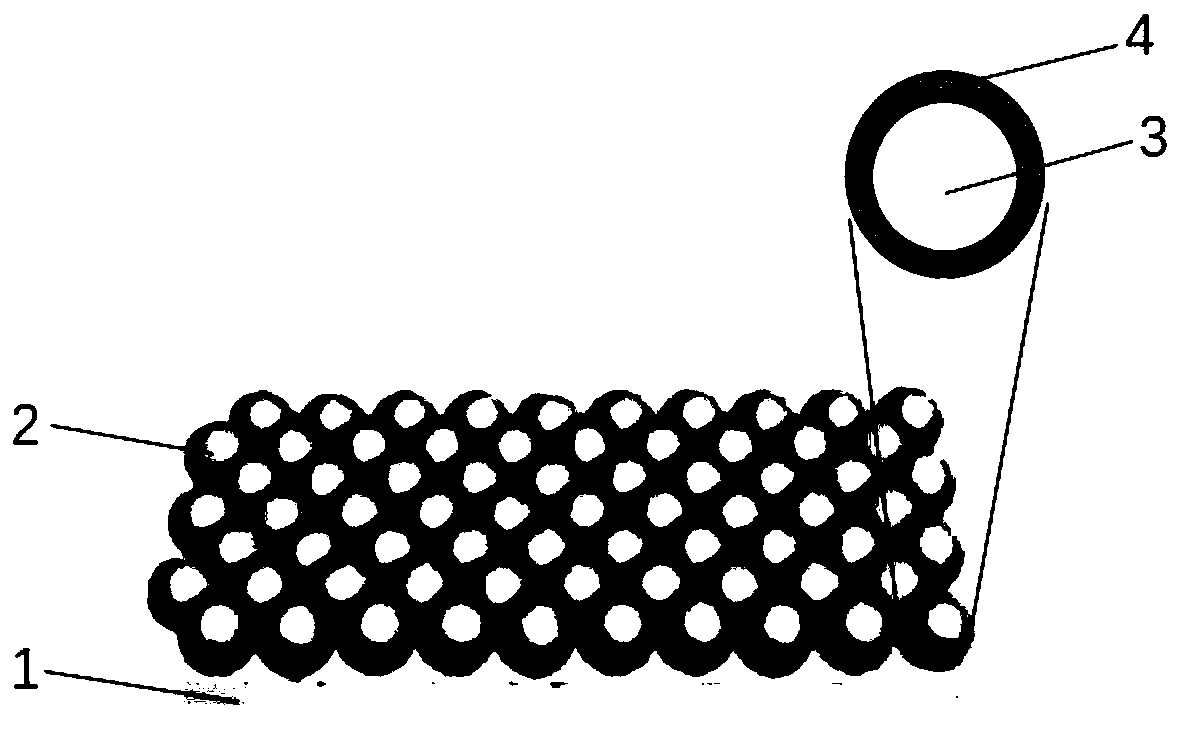

[0063] (1) Take a 500mL jar and two 50mL test tubes, pour about 40mL of deionized water into one of the test tubes, add 3g of red phosphorus flame retardant powder into the other test tube, and place a 30mm×5mm×1.5mm Insert half of the pure copper sheet vertically into the powder, put the two test tubes into the jar and place them in a drying oven at 80°C, the temperature can be controlled at 80°C, and the relative humidity is 75RH%;

[0064] (2) Carry out three groups of parallel tests, take out copper piece with tweezers after 14, 21, 28 days, transfer in the 50mL beaker that 10mL3.65wt% dilute hydrochloric acid is housed, seal the bottle mouth with plastic wrap, leave standstill for 48 hours;

[0065] (3) Take out the copper sheet, transfer the solution containing the corrosion product to a 10mL reagent bottle, and measure the content of phosphorus element with an inductively coupled plasma emission...

Embodiment 3

[0068] Embodiment 3 In the prior art, directly detect phosphine release amount (method 0)

[0069] (1) Put 3g of red phosphorus flame retardant into a 500mL dry gas collection bag, seal it and put it into a constant temperature drying oven at 80°C;

[0070] (2) Take out the collection bag after 14, 21, and 28 days respectively, connect the phosphine detector and the gas collection pump through a rubber hose, introduce the gas in the collection bag into the detector, detect the content of phosphine, and the test result as shown in Table 3.

[0071] Phosphine concentration in red phosphorus flame retardant tested by table 3 gas detector

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com