A long-distance, precise and fast pick-and-place chip device

A long-distance, chip technology, applied in the direction of transportation and packaging, electrical components, conveyor objects, etc., can solve the problem that the wafer pick-and-place structure cannot meet the long-distance transmission industrial production requirements at the same time, and cannot make the center of the loading nozzle visually positioned Center, unable to meet the needs of huge transfer of film loading capacity, etc., to achieve the effect of reducing motor load and moment of inertia, satisfying long-distance transmission, improving film loading efficiency and film loading yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention will be clearly and completely described below.

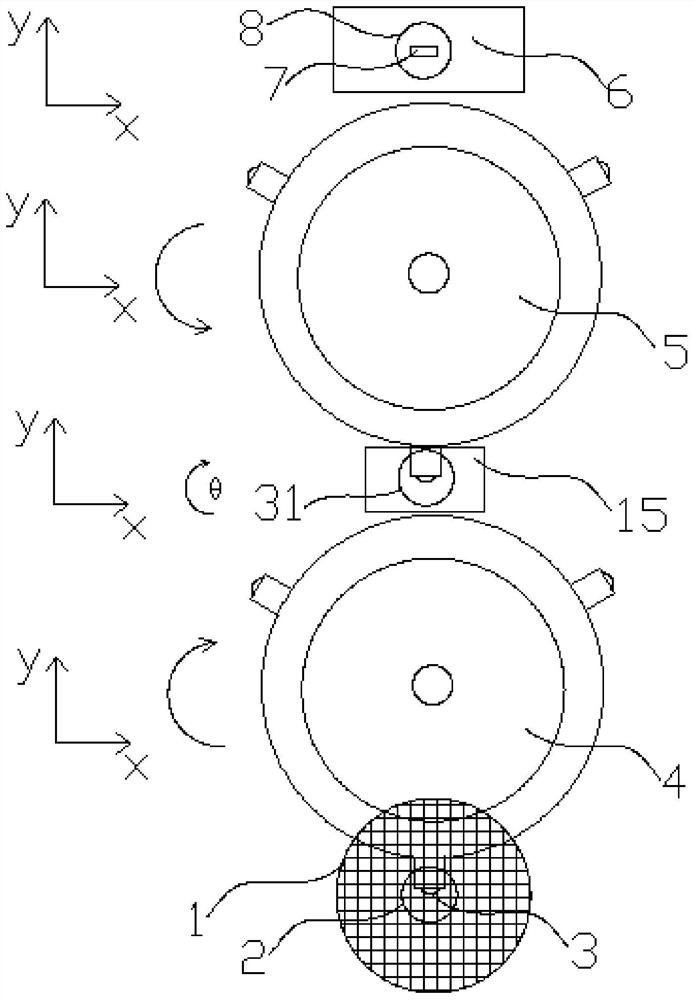

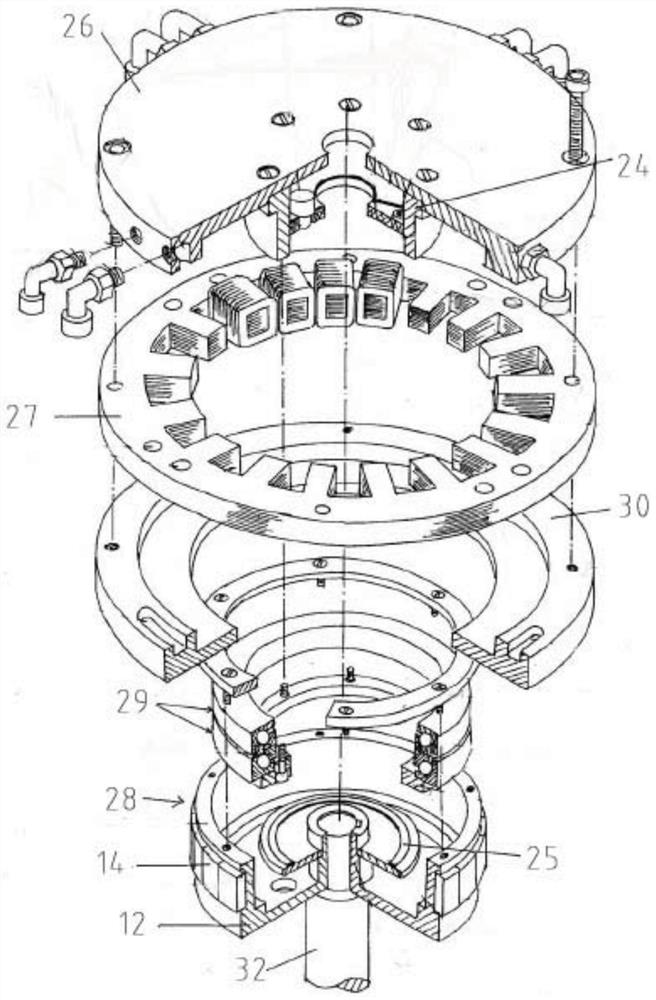

[0051] It should be noted that "horizontal", "vertical", "front", "rear", "left", "right", "upper" and "lower" refer to the attached Image 6 The direction in is also the direction of the use position of the long-distance, precise and quick pick-and-place chip device of the present invention. "X direction" and "Y direction" are relative to figure 1 with Figure 4 In terms of the coordinate system in , and figure 1 with Image 6 The coordinate system in is the result of the two representations in the same coordinate system.

[0052] Such as figure 1 As shown, a long-distance, precise and fast chip pick-up device includes a wafer stage and a wafer stage 6, the wafer stage is used to place a wafer 1, and the wafer stage 6 is used to place a substrate 7;

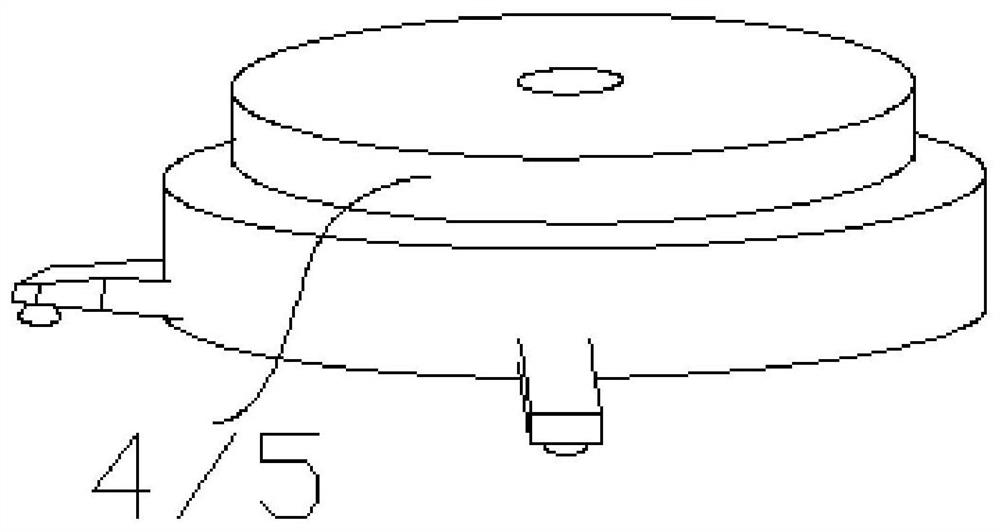

[0053] A first turret 4 and a second turret 5 are arranged between the wafer stage and the wafer stage 6, and at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com