A processing technology of surfacing welding Stellite hard alloy thin-wall sleeve

A hard alloy and processing technology, which is applied in the field of processing thin-walled shaft sleeves, can solve the problems of shaft sleeve deformation, welding cracks and large deformation, and achieve the goal of eliminating stress, improving processing accuracy, and ensuring the mechanical properties of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

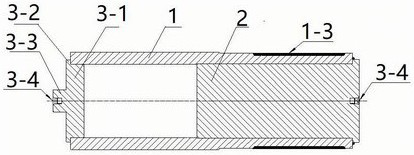

[0035] The present invention describes the technical solution of the present invention in detail as follows through specific embodiments. Include the following steps:

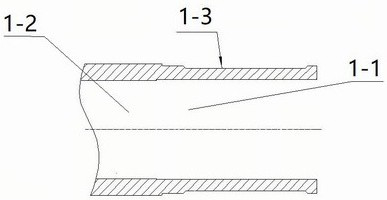

[0036] The outer dimension of the shaft sleeve is Φ220mm / Φ200mx700mm, and the material is stainless steel;

[0037] (1) Cutting: Cutting according to the outline size of the drawing, the wall thickness of the shaft sleeve is 10mm, the material of the shaft sleeve is the profile material, that is, the cylinder material, the inner hole and the outer circle are guaranteed to have a machining allowance of 5-10mm on one side, and the axial length The margin is guaranteed to be 15mm-20mm;

[0038] (2) heat treatment: rough blank is carried out heat treatment;

[0039] (3) Component analysis: process component analysis test block, carry out chemical component analysis according to GB / T11170 ASTMA240 standard;

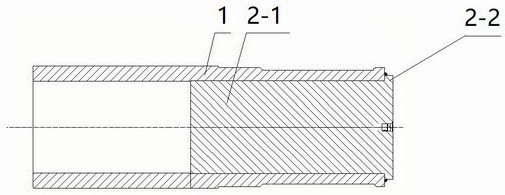

[0040] (4) Rough turning I: Carry out the size processing of the axle sleeve 1 before welding, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com