Full-automatic pipe welding machine and pipe welding process thereof

A pipe welding machine, fully automatic technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of popularization and use restrictions, deformation of thin-walled stainless steel pipes, low work efficiency, etc., to save human resources, high degree of automation, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

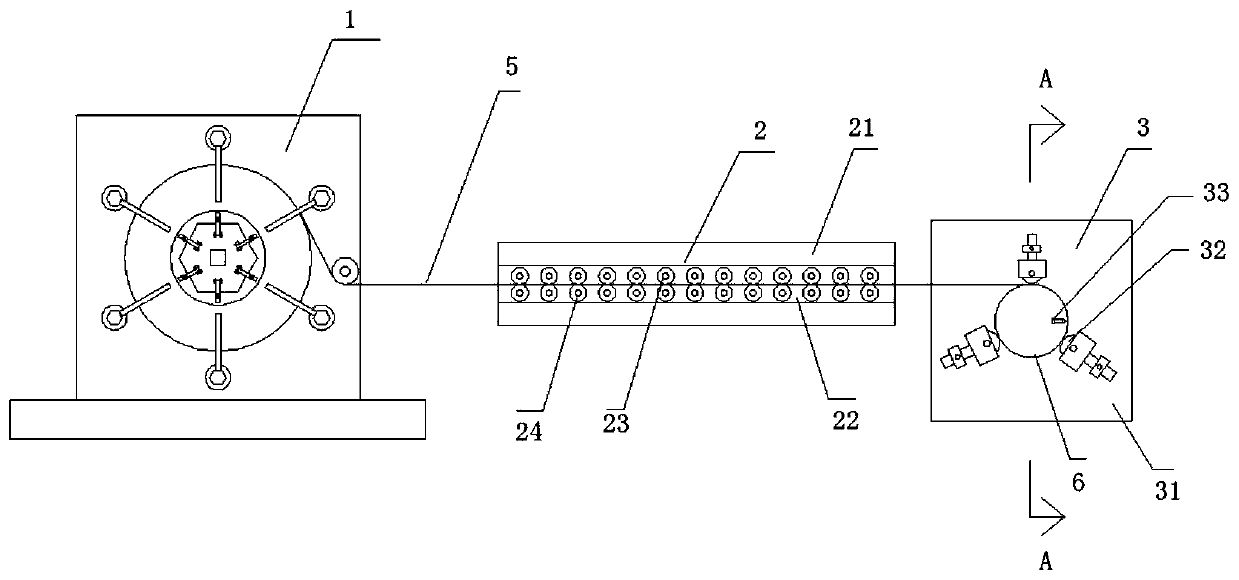

[0042] As shown in the figure, a fully automatic pipe welding machine includes:

[0043] The feeding device 1 is used for winding and feeding the steel plate 5;

[0044] The conveying device 2 is used to convey the loaded steel plate to the forming device;

[0045] The forming device 3 is used to position and form the steel plate and weld it;

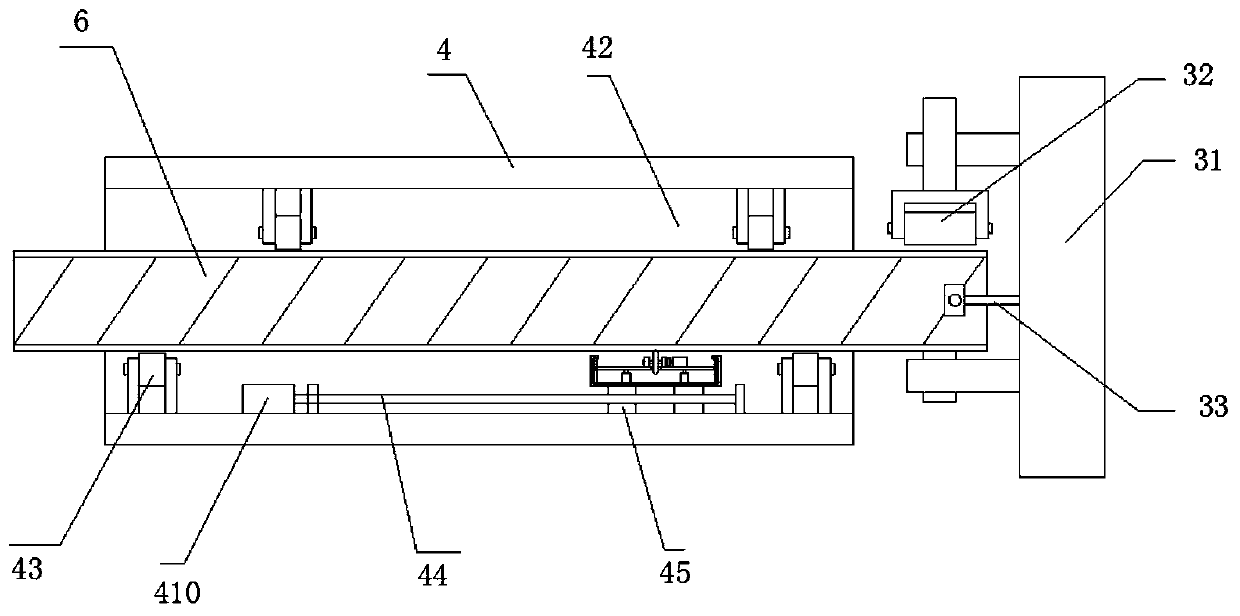

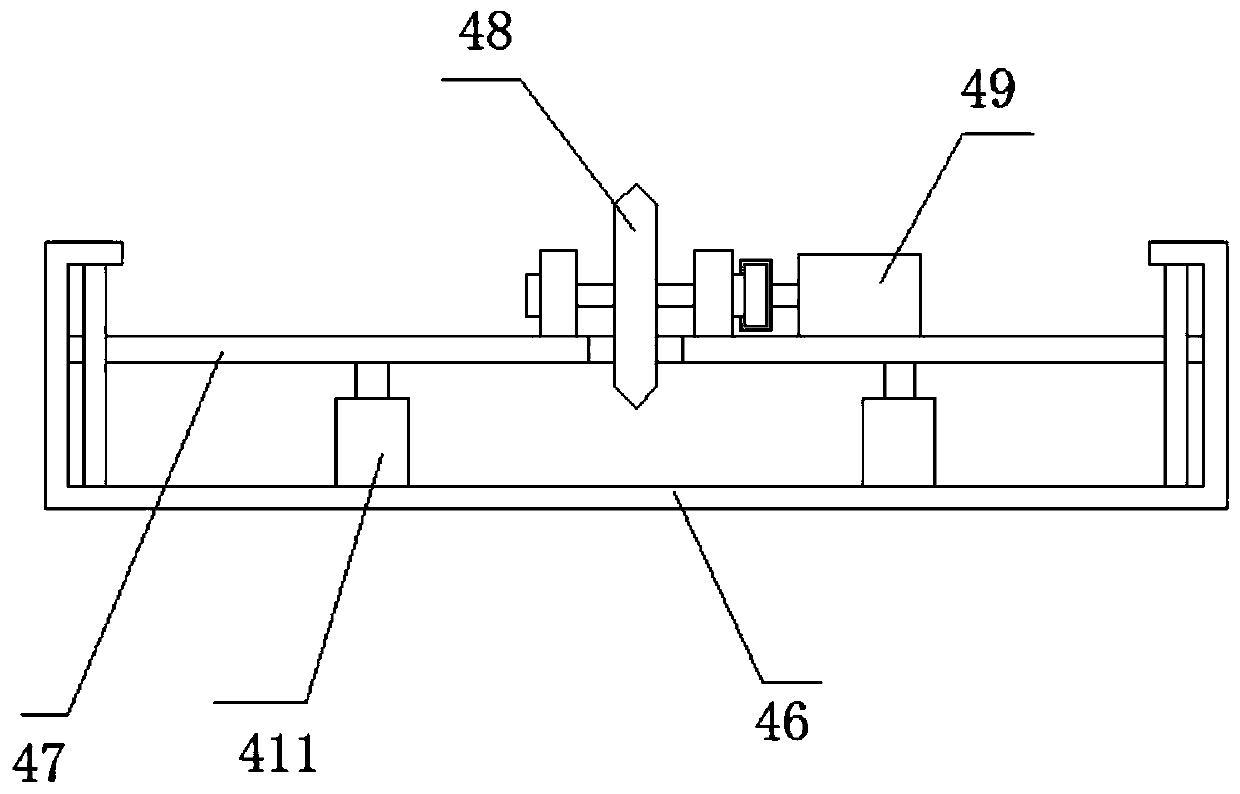

[0046] The cutting device 4 is used for cutting the pipe body 6 for welding and forming to length.

[0047] Further, the feeding device includes a base 11, a hollow rotating platform 12 is arranged on the base, a main support column 13 is fixed v...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap