Cr alloying steel without yield platform and preparation method thereof

An alloying, non-yielding technology, applied in the field of Cr alloyed steel and its preparation, can solve the problems of low operability and low operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

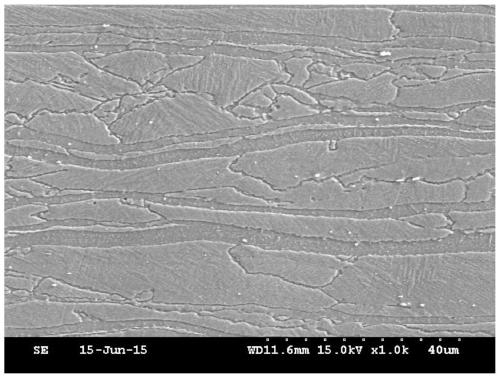

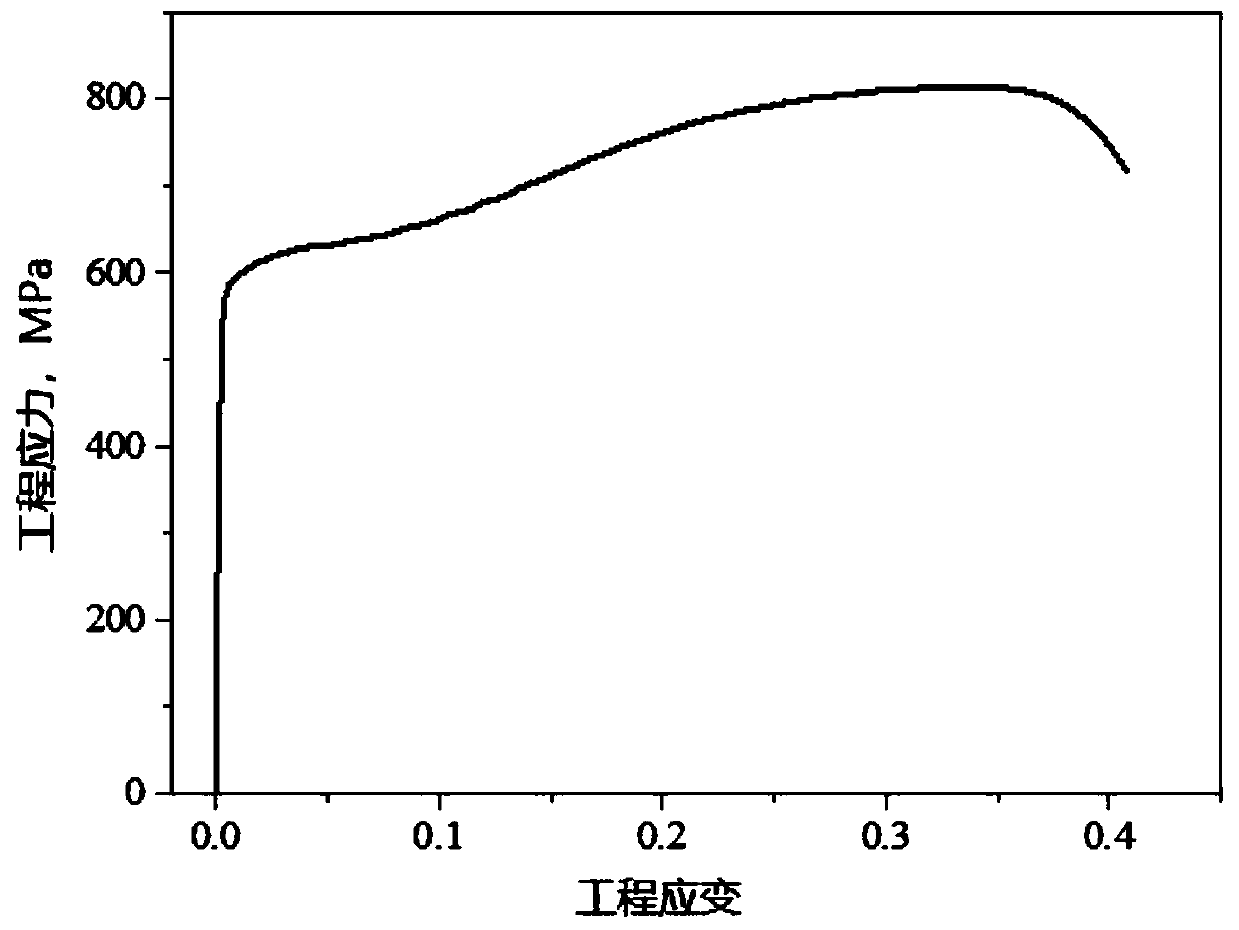

Image

Examples

Embodiment 1

[0062] This embodiment provides a Cr alloyed steel without a yield platform and a preparation method thereof, the steps comprising:

[0063] (1) Steel smelting: In this embodiment, the steel is smelted in a laboratory vacuum induction furnace and cast into a 50 kg square ingot. In this example, 5 furnaces of steel were smelted, numbered 1 to 5 respectively. The chemical composition corresponding to each steel number is shown in Table 1. The content corresponding to the elements in Table 1 is the mass percentage content. In each steel number, except for those corresponding to 1 in the table elements, the rest are Fe and unavoidable impurities.

[0064] Table 1 Chemical composition of No. 1 to No. 5 steel (unit: wt%)

[0065] steel number C mn Cr Al Si P S other 1 0.06 0.4 3.1 1.5 0.03 0.009 0.005 2 0.11 0.3 3.3 1.4 1.2 0.011 0.004 3 0.12 0.3 4.9 1.5 1.5 0.008 0.006 4 0.12 0.4 5.1 1.4 1.3 0.012 0.005 Nb:0....

Embodiment 2

[0076] This embodiment provides Cr alloyed steel with no yield platform and its preparation method. In this embodiment, No. 1-5 steel obtained in Embodiment 1 is prepared under different process conditions to obtain a group of cold-rolled plates. The preparation steps include:

[0077] (1) Steel smelting: No. 1-5 steel in Example 1 was used in this embodiment, smelted in a laboratory vacuum induction furnace, and cast into a 50 kg square ingot.

[0078] (2) Hot rolling: the hot rolling process is consistent with that of Example 1.

[0079] (3) Cold rolling: softening and annealing the hot-rolled plates corresponding to No. 1-5 steel. The softening and annealing process varies according to the chemical composition. The general principle is to heat to the two-phase region (800-1100 ° C) and keep it for about 1 hour. , pickling after cooling to room temperature, and finally cold rolling at room temperature. The cold rolling reductions of 1-5# steel in this embodiment are all 50%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com