Diamond bit

A diamond drill bit and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of single water hole effect, limited debris flushing force, and limited number of drill teeth, etc., and achieve the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

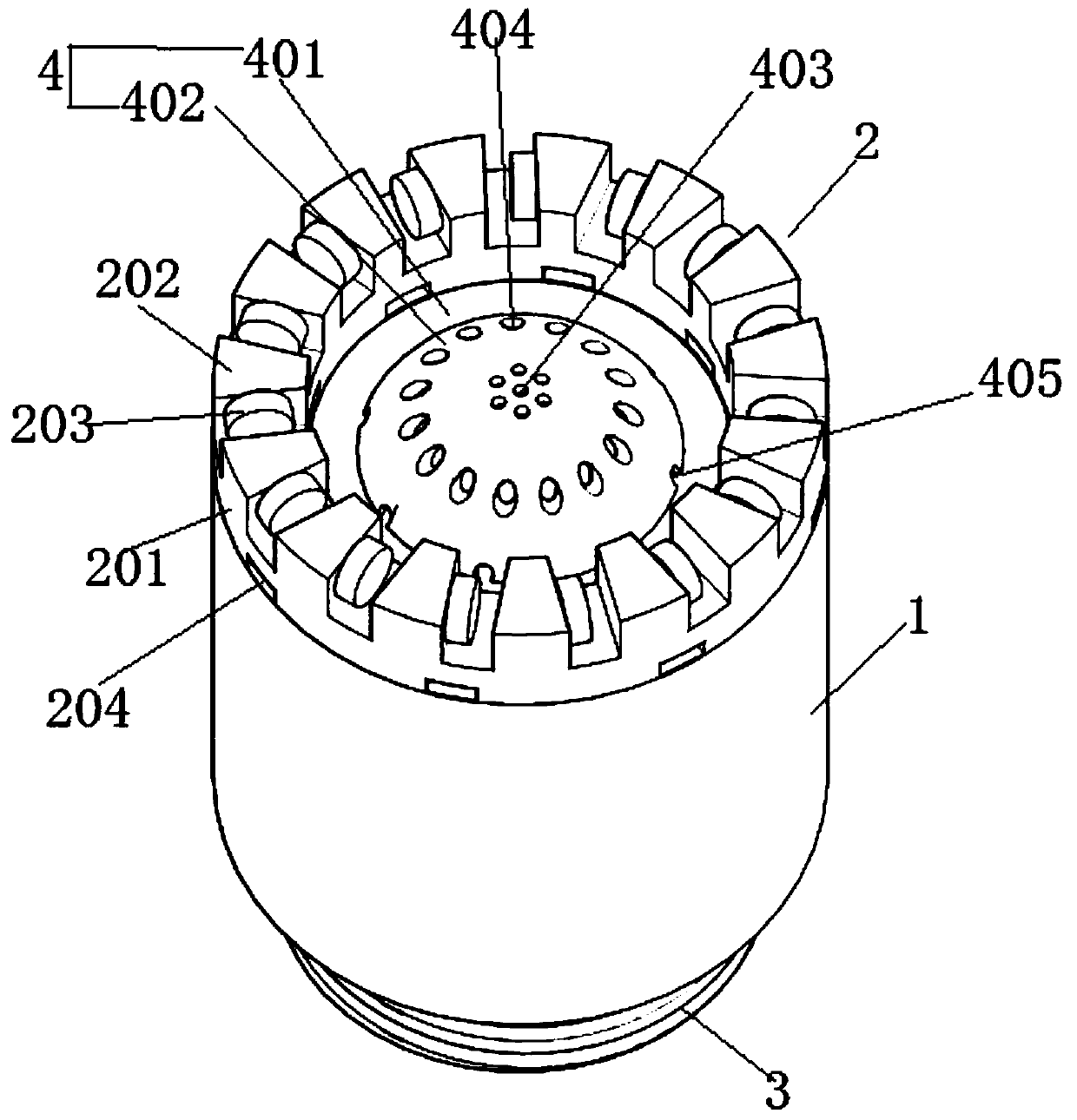

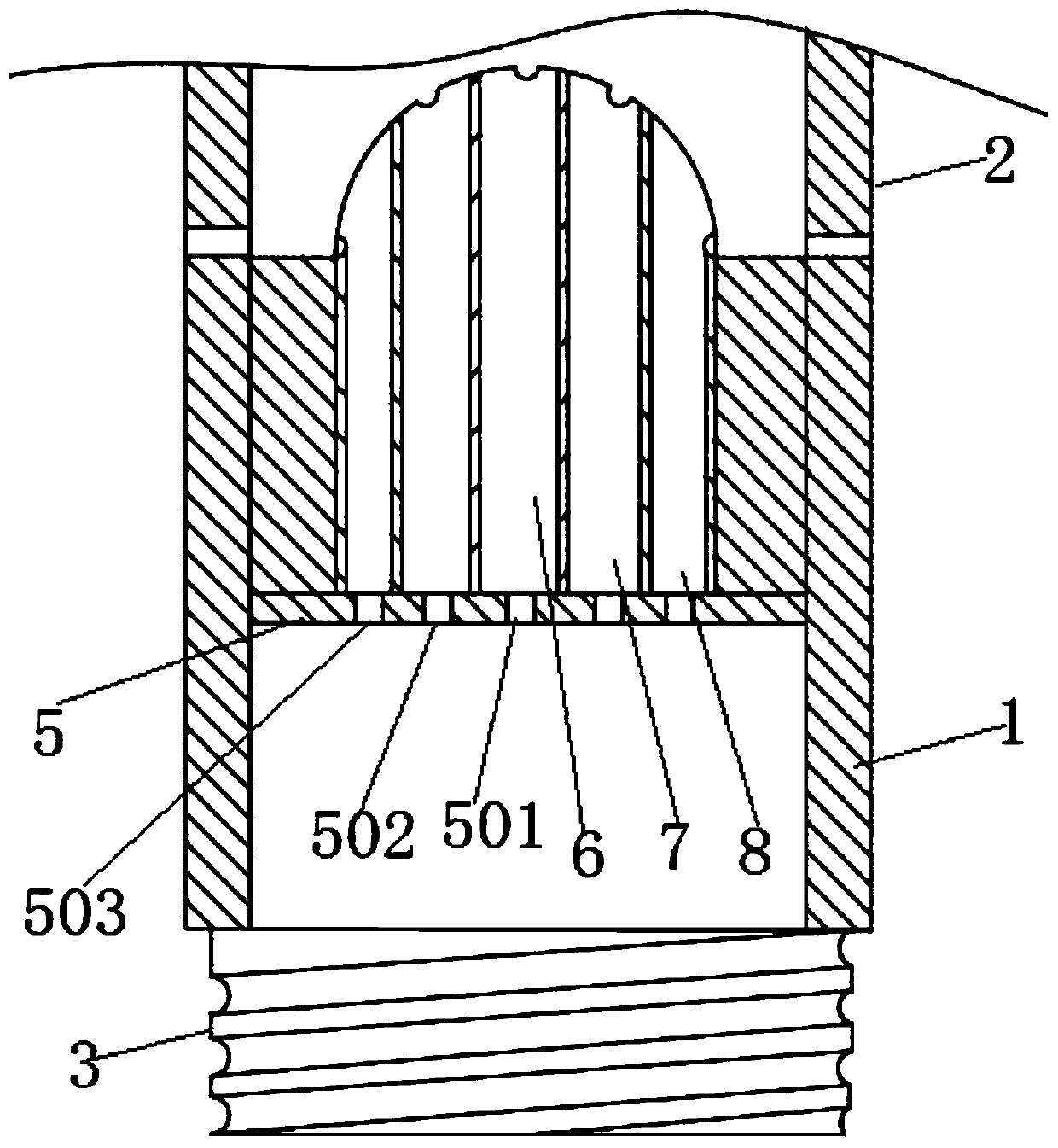

[0020] Such as figure 1 with figure 2 In the shown embodiment, a kind of diamond drill bit comprises a drill bit steel body 1, a drill tooth section 2 arranged at the upper end of the drill bit steel body 1 and a threaded connection pipe section 3 arranged at the lower end of the drill bit steel body 1, and the drill tooth section 2 includes The integrally formed annular end 201 and the fan-shaped end 202 evenly spaced above the annular end 201, the left side of the fan-shaped end 202 is provided with a circular drill block 203, and the bottom of the annular end 201 is evenly provided with a debris discharge port 204, The top of the drill bit steel body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com