Cooler applicable to wind generating set

A technology for wind turbines and coolers, applied in wind turbines, wind power generation, engines, etc., can solve the problems of waste of production labor, loss of imported wind flow, clogging of filters, etc. blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

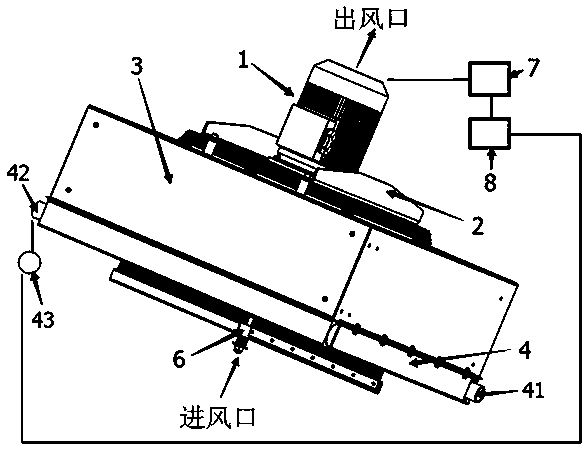

[0032] A cooler suitable for wind power generating sets, which is controlled by a motor 1, a forward and reverse control module 7, a motor bracket 2, a cover body 3, a cooling core 4, fan blades 5, a cleaning device 6, a temperature sensor 43, and a PLC Device 8 is composed.

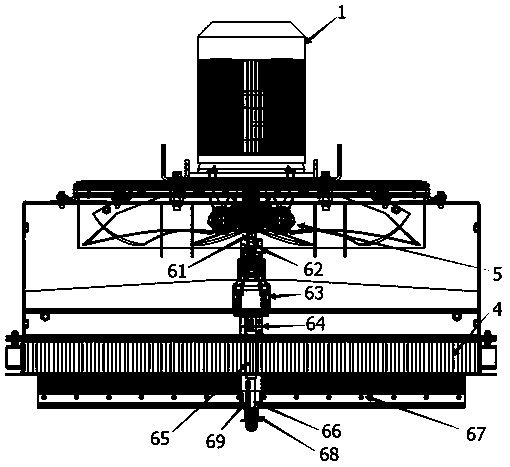

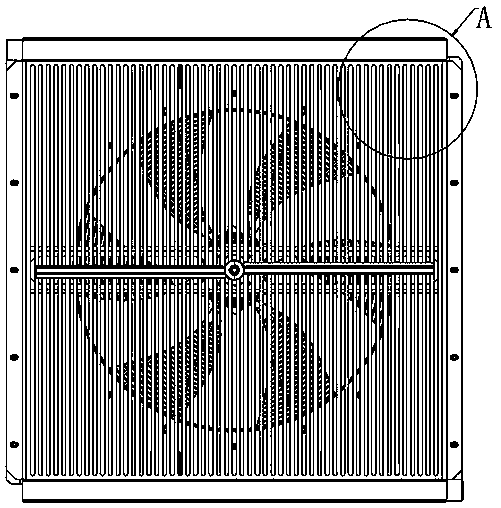

[0033] The cooling core 4 is placed at the front end of the motor 1 (shaft), the output end of the motor shaft is fixedly connected to the first transmission shaft 61 , and the fan blade 5 is fixedly connected to the first transmission shaft 61 . The output end of the first transmission shaft 61 is connected to the speed reducer 63 through the clutch 62 in turn, and then the second transmission shaft 65 is linked through the coupling 64; the second transmission shaft 65 passes through the reserved round hole at the center of the cooling core 4, Rotate cleaning device 6.

[0034] The cleaning device 6 is made up of a hair brush 67 , a hair brush skeleton 66 and a progressive device 68 . The hairbrush 67...

Embodiment 2

[0043] Based on the structure of Embodiment 1, a temperature sensor 43 is provided at the liquid outlet 42 of the coolant, and is connected to the PLC controller 8; the PLC controller 8 controls forward rotation and reverse rotation of the motor 1 according to the feedback of the temperature sensor 43 .

[0044] When the temperature of the liquid outlet 42 increases, the cooling effect decreases, and the surface of the cooling core 4 is blocked, and the temperature sensor 43 transmits a signal to the PLC controller 8 through the data line, and the PLC controller 8 controls the motor 1 to stop normal operation (positive Turn), enter the reverse cleaning state, and the cleaning time can be set according to the particulate matter environment in the air of each area. After the cleaning is finished, the PLC controller 8 controls the motor 1 to work normally (forward rotation), and at the same time the clutch 62 disengages from the engagement with the reducer 63, and the cleaning dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com