A garbage smoldering pyrolysis device

A pyrolysis and smoldering technology, which is applied in the direction of combustion type, combustion method, lighting and heating equipment, etc., can solve the problems of complex operation of the overall equipment, low waste disposal efficiency, and insufficient utilization, so as to improve energy utilization efficiency, Long path, full smoldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

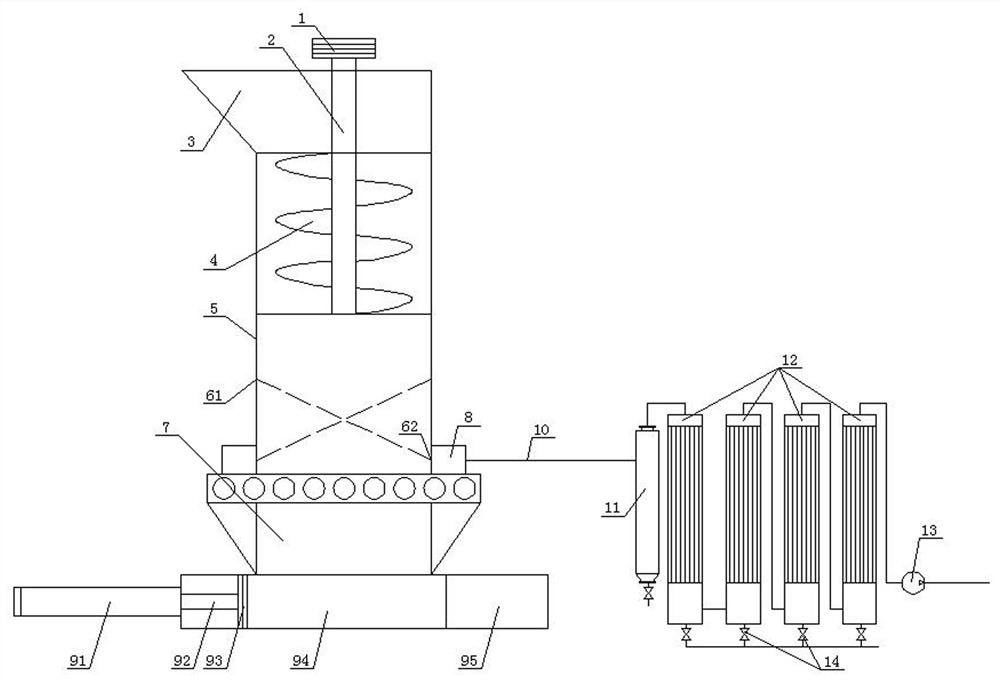

[0019] The present invention will be further described below in conjunction with the drawings.

[0020] Such as figure 1 As shown, the present invention includes a pyrolysis cylinder 5, an open feed port 3 is installed on the top of the pyrolysis cylinder 5, and a vertically arranged shaft is rotatably connected to the open feed port 3 through a support frame. 2. The rotating shaft 2 extends downwards to the lower part of the open feed port 3. A screw extrusion blade 4 is provided on the rotating shaft 2 below the open feed port 3; a slag discharge is provided at the bottom of the pyrolysis cylinder 5 A carbon slag processor is installed at the slag outlet of the slag discharger 7; a plurality of suction air groups are provided around the circumference at the bottom of the side wall of the pyrolysis cylinder 5, and the suction air groups are located on the spiral extrusion blades 4 Below, the suction air group includes an air inlet 61 and an air outlet 62, the air inlet 61 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com