Heat exchanger

A heat exchanger and heat exchanger technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as environmental damage, greenhouse effect and acid rain, and achieve extended service life, accelerated heat transfer, The effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

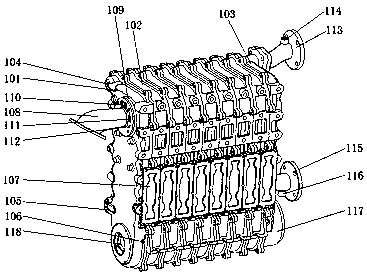

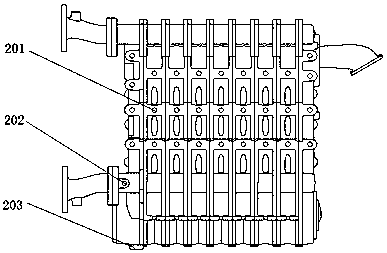

[0016] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific diagrams.

[0017] A preferred embodiment of the present invention is to provide a heat exchanger, the purpose of which is to adopt a special structure of water channel ribs to speed up the heat transfer from the water channel surface to the fluid body, strengthen the turbulent state, and fundamentally solve the problem of heat transfer. The accumulation of dirt on the heat transfer surface of the heat exchanger often produces additional thermal resistance to heat transfer, which reduces the total thermal conductivity, electrochemical corrosion and chemical corrosion, which greatly improves the heat transfer efficiency of the heat exchanger, enhances the corrosion resistance, and effectively prolongs the life of the heat exchanger. Long service life, simple structure, easy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com