Evaluation method for quality of high-purity silicon carbide powder

A technology of high-purity silicon carbide powder and high-purity silicon carbide, which is applied to the analysis of materials, material analysis through optical means, and measurement devices, etc., can solve the problem of inability to comprehensively reflect the true quality of silicon carbide raw materials, high measurement costs, and long measurement cycles. and other problems, to achieve the effect of fast and effective test results, timely adjustment, and improvement of synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

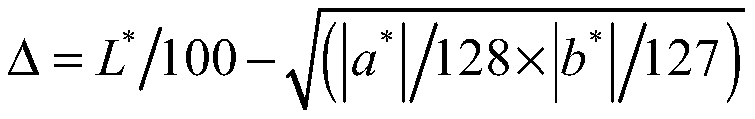

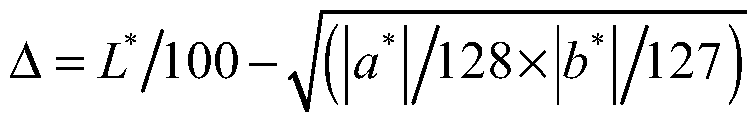

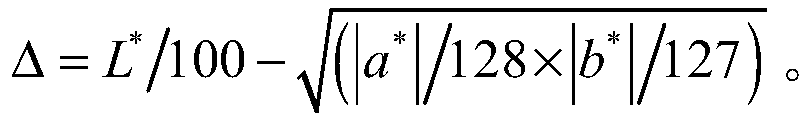

[0024] In the actual application of synthetic silicon carbide powder, the powder in different parts of the same furnace and the powder in the same part of different furnaces are taken for measurement, and the quality coefficient is calculated according to the lightness value and chromaticity value, and the quality control is carried out according to the quality factor , according to the change of quality coefficient, the process of synthetic powder should be adjusted appropriately.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com