Endoscope dedicated for substation maintenance

An endoscope, stepper motor technology, applied in telescopes, instruments, optics, etc., can solve the problems of safe and stable operation of the power grid, discharge, short circuit, etc., to reduce maintenance costs and difficulties, simple operation, and reduce power outages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

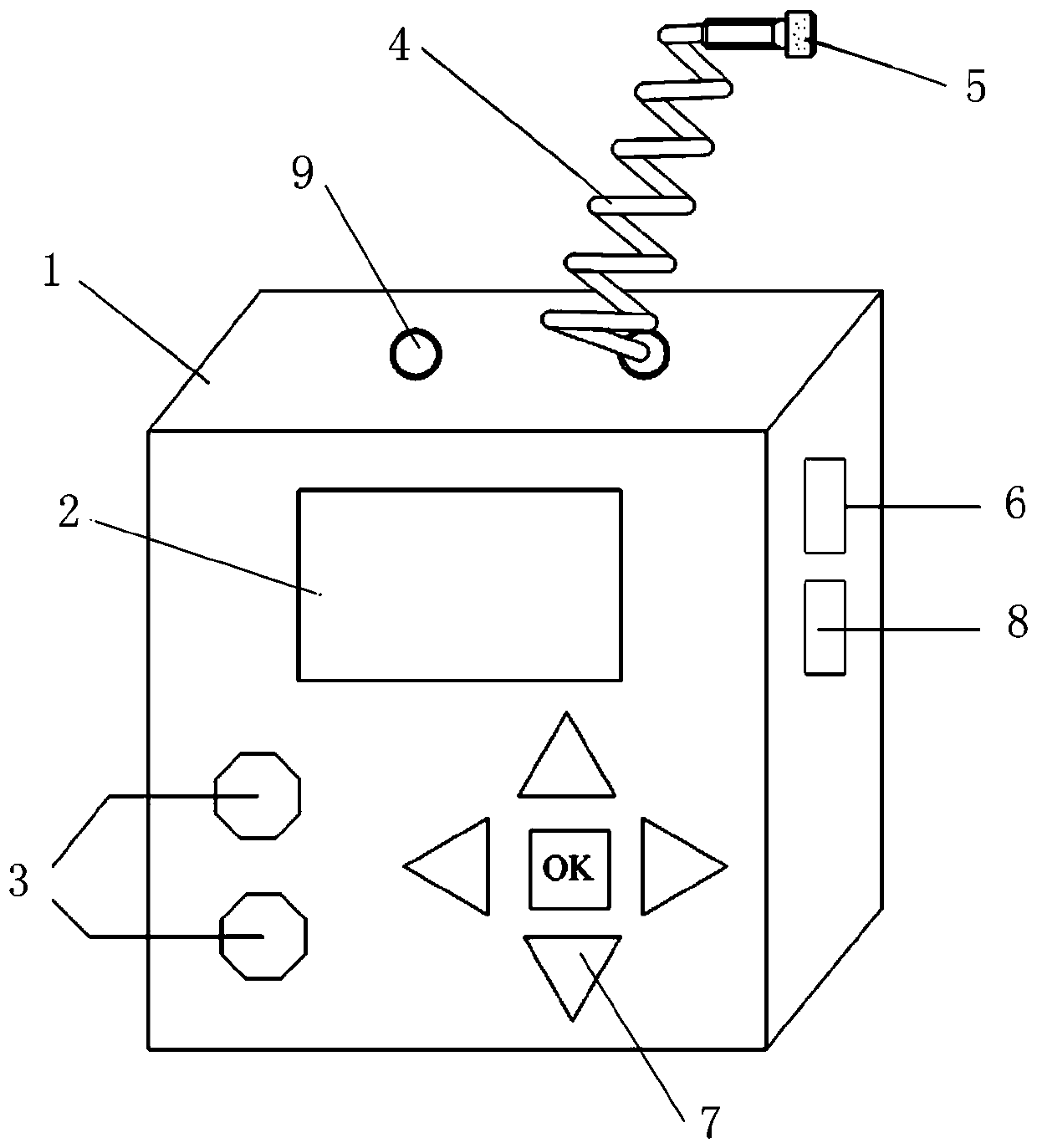

[0044] as attached figure 1 shown;

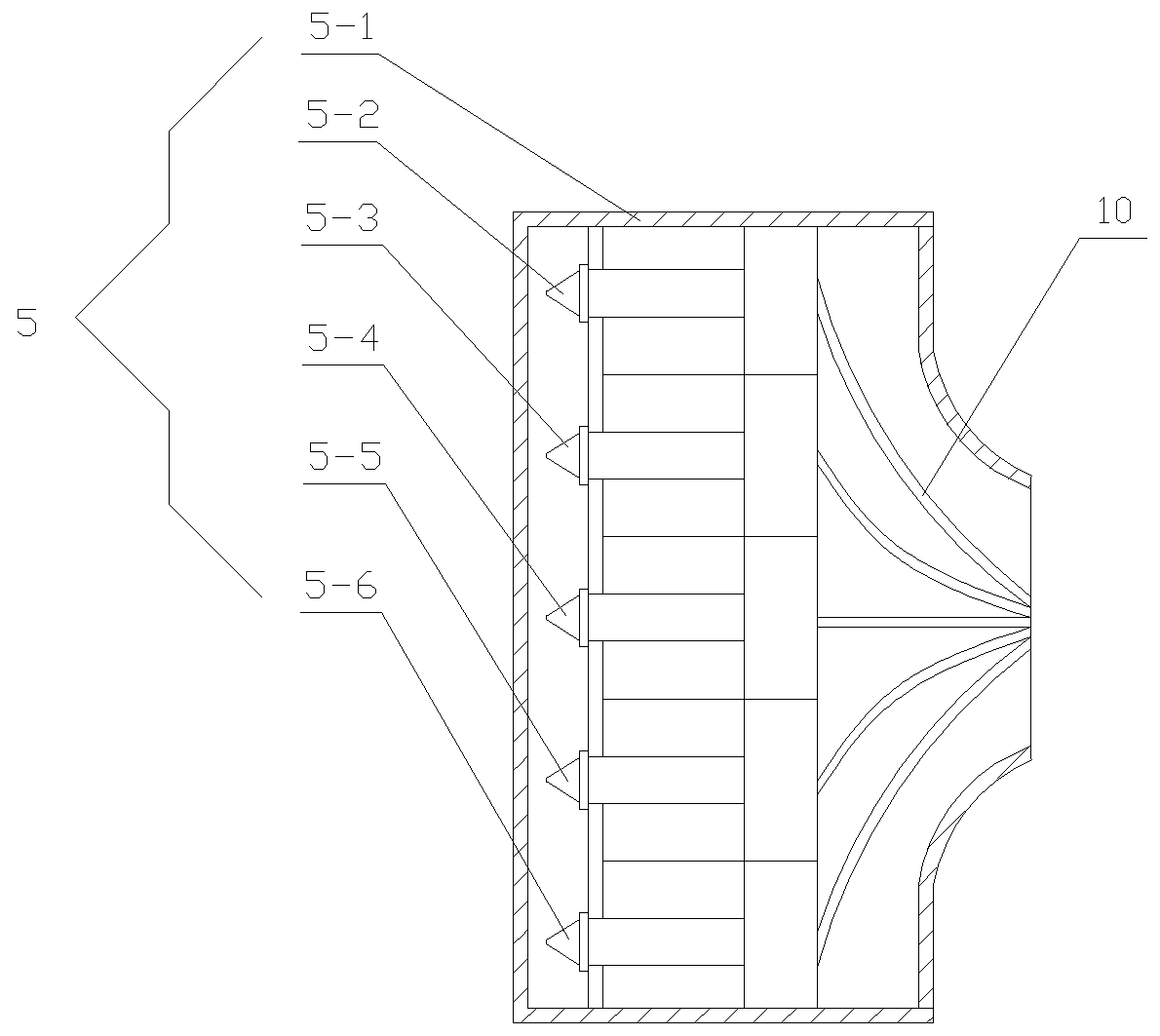

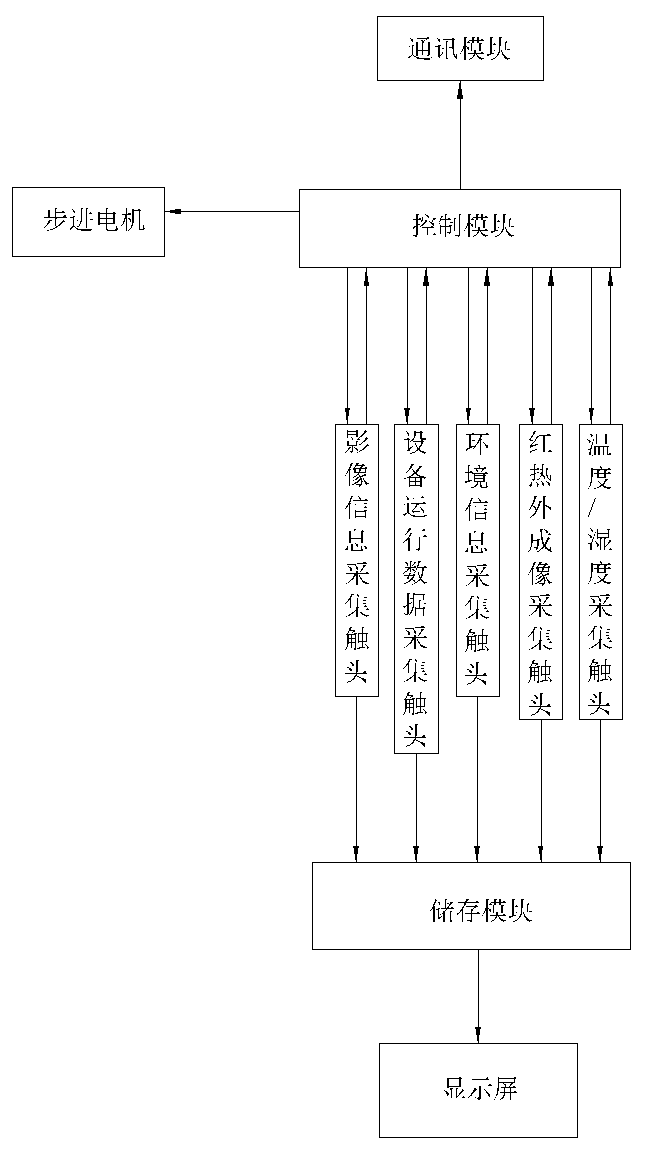

[0045] A special endoscope for substation maintenance, including a host 1, a stepper motor and a control module fixedly installed in the host 1, an endoscope telescopic conduit 4 connected to the top outside of the host 1, and an endoscope telescopic conduit 4 installed The collection probe assembly 5 of the part;

[0046] The control module is connected to the acquisition probe assembly 5 through a data transmission wire 10;

[0047] The power shaft of the stepping motor is connected with a soft steel wire transmission shaft, and the soft steel wire transmission shaft passes through the telescopic catheter 4 of the endoscope.

[0048] Further, a rocker control mechanism 3 for controlling the direction of the soft wire transmission shaft is provided outside the main machine 1 .

[0049] Further, a display screen 2 , a probe adjustment button 7 and a working status indicator light 9 are provided on the outside of the host 1 , which are re...

Embodiment 2

[0059] as attached Figure 1-3 shown;

[0060] A special endoscope for substation maintenance, including a host 1, a stepper motor and a control module fixedly installed in the host 1, an endoscope telescopic conduit 4 connected to the top outside of the host 1, and an endoscope telescopic conduit 4 installed The collection probe assembly 5 of the part;

[0061] The control module is connected to the acquisition probe assembly 5 through a data transmission wire 10;

[0062] The power shaft of the stepping motor is connected with a soft steel wire transmission shaft, and the soft steel wire transmission shaft passes through the telescopic catheter 4 of the endoscope.

[0063] Further, a rocker control mechanism 3 for controlling the direction of the soft wire transmission shaft is provided outside the main machine 1 .

[0064] Further, a display screen 2 , a probe adjustment button 7 and a working status indicator light 9 are provided on the outside of the host 1 , which are...

Embodiment 3

[0077] as attached Figure 1-3 shown;

[0078] A special endoscope for substation maintenance, including a host 1, a stepper motor and a control module fixedly installed in the host 1, an endoscope telescopic conduit 4 connected to the top outside of the host 1, and an endoscope telescopic conduit 4 installed The collection probe assembly 5 of the part;

[0079] The control module is connected to the acquisition probe assembly 5 through a data transmission wire 10;

[0080] The power shaft of the stepping motor is connected with a soft steel wire transmission shaft, and the soft steel wire transmission shaft passes through the telescopic catheter 4 of the endoscope.

[0081] Further, a rocker control mechanism 3 for controlling the direction of the soft wire transmission shaft is provided outside the main machine 1 .

[0082] Further, a display screen 2 , a probe adjustment button 7 and a working status indicator light 9 are provided on the outside of the host 1 , which are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com