Toner and preparation method thereof

A technology of toner and crosslinking agent, which is applied in the field of toner and its preparation, and can solve problems such as undiscovered toner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a toner, and its preparation method specifically includes the following steps:

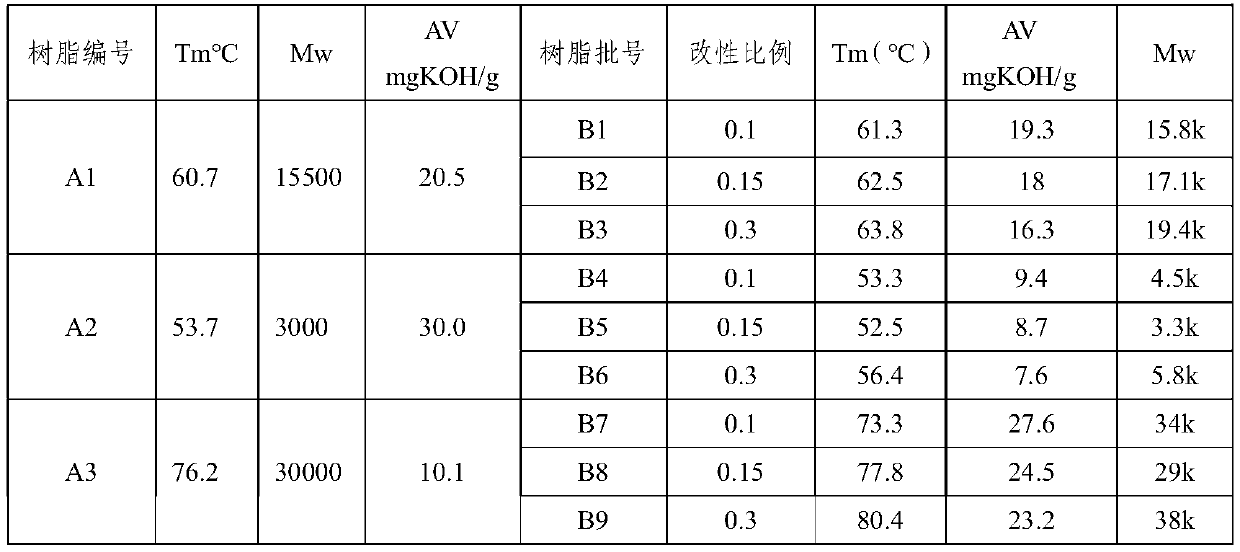

[0061] (1) Synthesis of unsaturated crystalline polyester resin A1

[0062] In a four-neck flask connected with a nitrogen introduction tube, a condenser, a dehydration tube and a stirrer, add 195 parts of dimethyl terephthalic acid in parts by mass and stir at 150°C for 1 hour, then add 85 parts of maleic glycol . Afterwards, raise the temperature to 200°C and continue the reaction for 5 hours, judge the loss of maleic glycol by analyzing the theoretical reaction water content of the distillate, add diethylene glycol for compensation, and continue the reaction for 3 hours to obtain an unsaturated crystalline polyester resin A1. The melting point Tm of the unsaturated crystalline polyester resin A1 was 60.7°C, the weight average molecular weight Mw was 15500, and the acid value of the unsaturated crystalline polyester resin was 20.5 mg KOH / g.

[0063] (1-2) Synth...

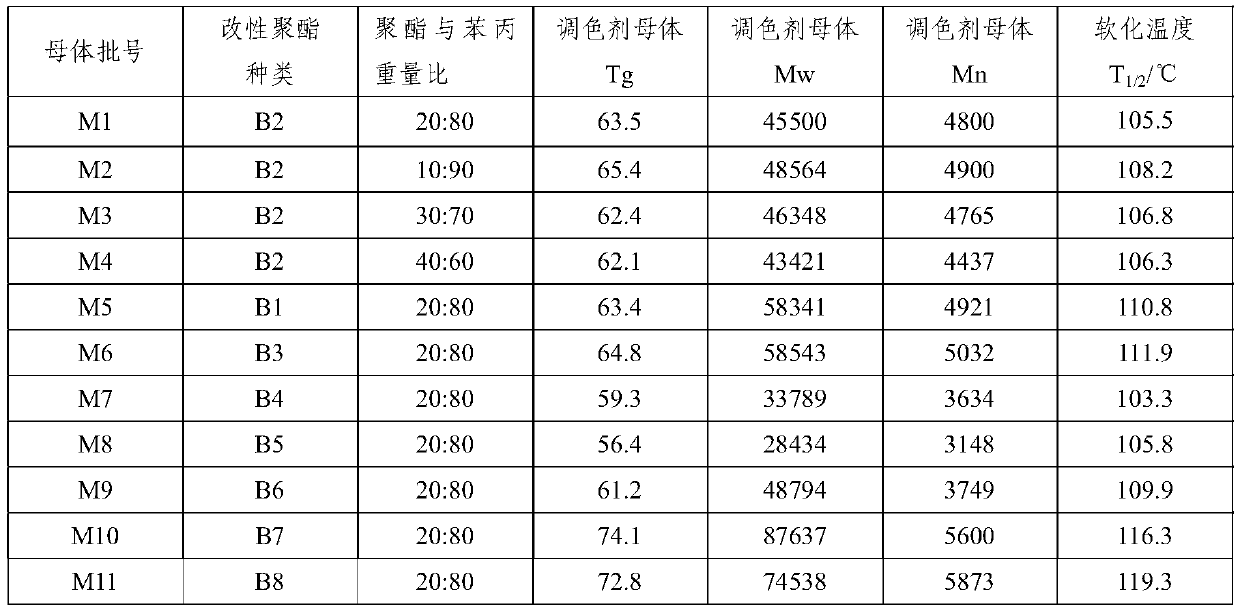

Embodiment 2

[0083] This example provides a toner, the preparation method of which is different from Example 1 only in that 20 parts of unsaturated crystalline polyester resin B2 modified by a triazine crosslinking agent is replaced by 8.9 parts of triazine in step (4) Unsaturated crystalline polyester resin B2 modified by similar cross-linking agent to obtain toner matrix M2 and finally toner T2.

Embodiment 3

[0085] This example provides a toner, the preparation method of which is different from Example 1 only in that in step (4), 20 parts of unsaturated crystalline polyester resin B2 modified by a triazine crosslinking agent is replaced by 34.3 parts of triazine Unsaturated crystalline polyester resin B2 modified by a similar cross-linking agent to obtain toner matrix M3 and finally toner T3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com