Environmentally-friendly developer and manufacturing method thereof

A developer and environmentally friendly technology, applied in the field of environmentally friendly developer, can solve the problems of increased adhesive force of developer, worsening of developer frictional charging uniformity, and lower yield, so as to suppress cold fixing offset and hot fixing offset. The effects of shifting, improving the uniformity of triboelectric charging, and increasing the rate and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

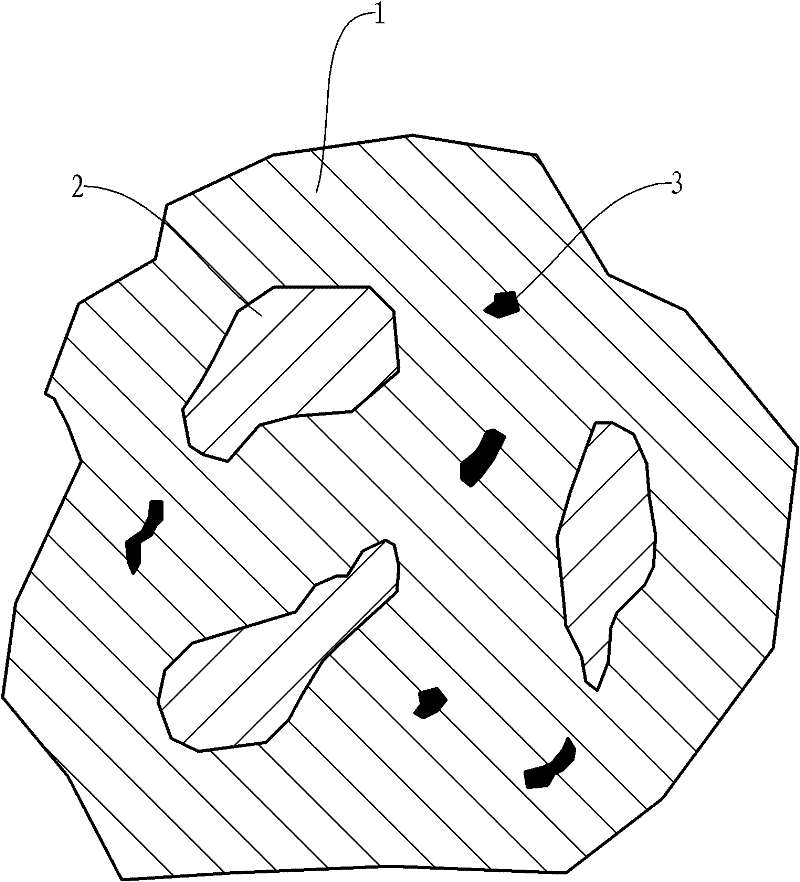

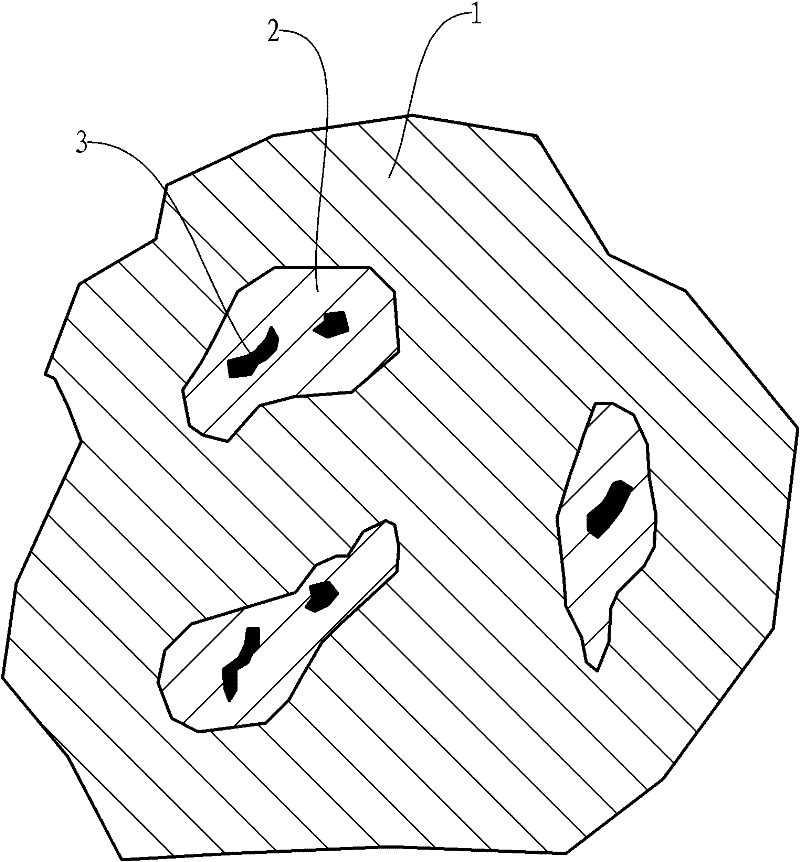

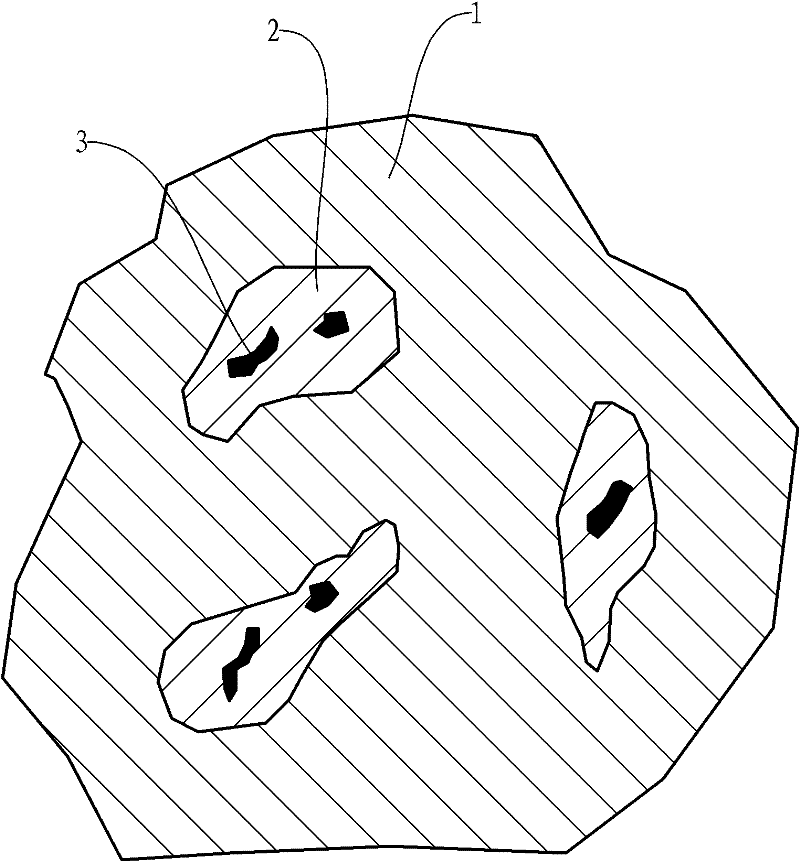

Image

Examples

preparation example Construction

[0042] Preparation of powder W-1

[0043] Prepare 100 parts by weight of polylactic acid bioresin (Tg: 62°C, T1 / 2: 160°C), 5 parts by weight of polypropylene wax (Tm: 145°C), mix them with a Henschel high-speed mixer, and then mix the mixed materials Melt kneading and extrusion is carried out on a twin-screw extruder. The melt temperature of the melt kneading is controlled at about 175°C. The material extruded by kneading is rapidly cooled by a blower, and then coarsely crushed into particle size on a hammer crusher. powder of 0.1-2mm to obtain powder W-1.

[0044] Preparation of powder W-2

[0045] Prepare 100 parts by weight of polylactic acid bioresin (Tg: 58°C, T1 / 2: 150°C), 40 parts by weight of polypropylene wax (Tm: 110°C), mix them with a Henschel high-speed mixer, and then mix the mixed materials Melt mixing and extrusion is carried out on a twin-screw extruder. The melt temperature of the melt mixing is controlled at about 165°C. The material extruded by mixing is ...

Embodiment 1

[0051] Prepare 100 parts by weight of styrene-butyl acrylate resin (Tg: 57°C, T1 / 2: 141°C), 60 parts by weight of W-1, 10 parts by weight of carbon black, and 3 parts by weight of azo-iron complex, using Henry The Scheer high-speed mixer is used for mixing, and then the mixed materials are melted, kneaded and extruded on the twin-screw extruder. The temperature of the melted kneaded melt is controlled at about 165 ° C. Cool, then coarsely crush into powders with a particle size of 0.1-2mm on a hammer-type coarse crusher, and then finely crush and classify the coarsely crushed powder on a jet mill classifier to obtain an MVD of 9 microns and a P>5 of 88 % micropowder, then get 100 parts by weight of micropowder, 1 part by weight of silicon dioxide (such as R202 produced by Degussa company), and 0.1 part by weight of zinc stearate micropowder (MVD is 100nm) on the Henschel high-speed mixer Fully post-mix, and finally sieve through an ultrasonic vibration sieving machine to obtai...

Embodiment 2

[0053] Prepare 100 parts by weight of polyester resin (Tg: 57°C, T1 / 2: 135°C), 15 parts by weight of W-2, 120 parts by weight of ferroferric oxide magnetic powder, and 3 parts by weight of azo-iron complex. The Scheer high-speed mixer is used for mixing, and then the mixed materials are melted and kneaded on the twin-screw extruder. Cool, then coarsely crush into powders with a particle size of 0.1-2mm on a hammer-type coarse crusher, and then finely crush and classify the coarsely crushed powder on a jet mill classifier to obtain an MVD of 8 microns and a P>5 of 83 % micropowder, then get 100 parts by weight of micropowder, 1 part by weight of silicon dioxide (such as R202 produced by Degussa company), and 0.1 part by weight of zinc stearate micropowder (MVD is 100nm) on the Henschel high-speed mixer Fully post-mix, and finally sieve through an ultrasonic vibration sieving machine to obtain the environment-friendly developer of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com