a food processor

A technology of food processing machines and circuit boards, applied in the direction of electrical program control, instruments, kitchen utensils, etc., can solve the problems of cost electromagnetic, processing, manufacturing cost, installation complexity increase, signal detection inaccuracy, etc., to reduce cost and volume Effects of size, coupler port saving, and port resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

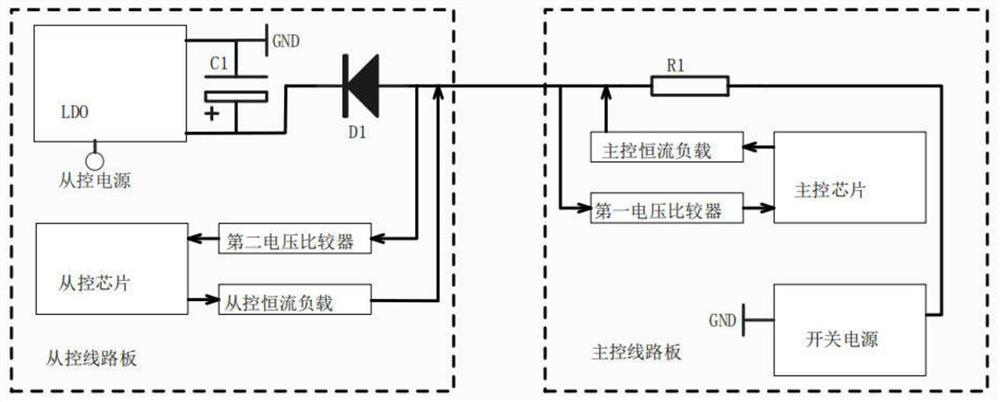

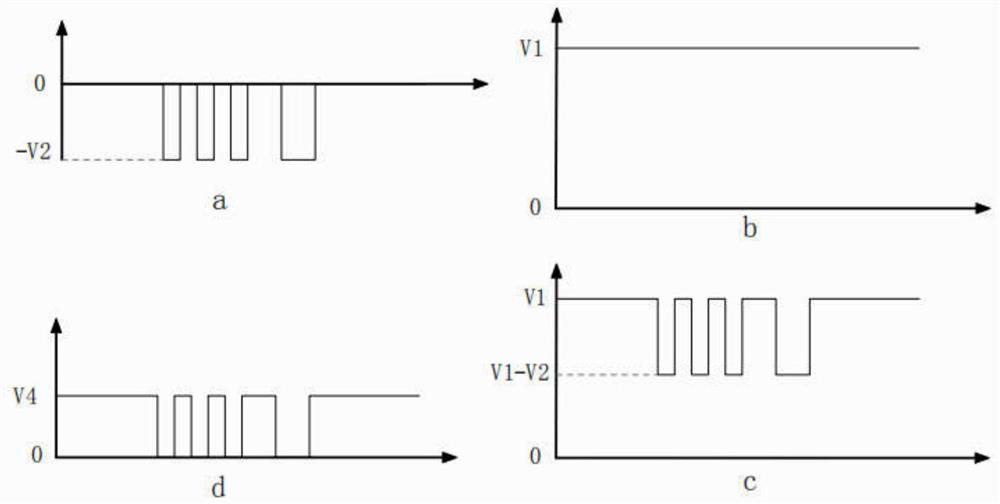

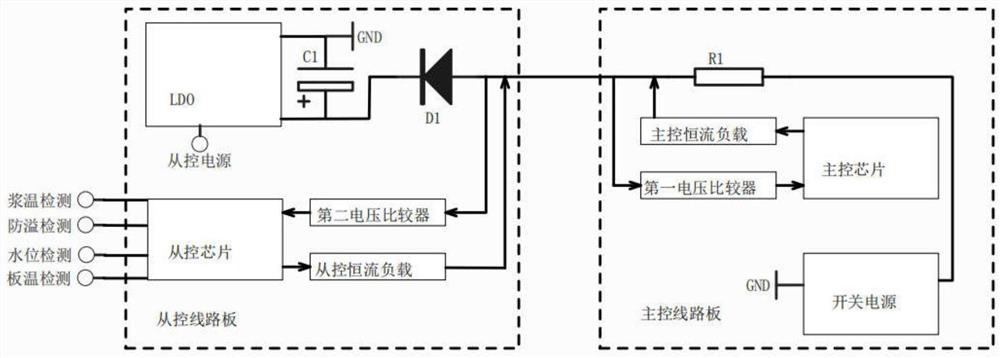

[0022] A food processor such as figure 1 As shown, it includes a main control circuit board and a slave control circuit board. The main control circuit board communicates with the slave control circuit board. The main control circuit board is provided with a power module. In this embodiment, the power module is A switching power supply, the switching power supply outputs a first DC power supply of voltage V1, the first DC power supply is electrically connected to the slave control circuit board through a power supply line, and the main control circuit board uses the first DC power supply The power supply is a baseband signal, and the main control communication signal is modulated into a carrier signal and transmitted to the slave control circuit board. The slave control circuit board is provided with an LDO voltage regulator, and the carrier signal is output after passing through the LDO voltage regulator. As for the slave control power supply, the slave control circuit board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com