Diesel engine fault diagnosis method based on tensor Tucker decomposition fuzzy control

A fuzzy control and fault diagnosis system technology, applied in the direction of reasoning methods, measuring devices, computer components, etc., can solve problems such as economic loss, signal mutual interference, large nonlinear and complex coupling, casualties, etc., to improve accuracy, Reduce external interference and mutual interference between signals, and solve the effect of one cause and multiple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

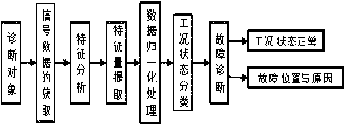

[0018] The specific implementation of the diesel engine fault diagnosis method based on tensor Tucker decomposition fuzzy control is as follows.

[0019] The step 1 of collecting data signals from sensors in the ECU includes: an air flow meter, a coolant temperature sensor, an intake manifold pressure sensor, a regulating piston movement sensor, an engine speed sensor, and the like.

[0020] The second step is to construct a third-order tensor composed of signal category, rotational speed and crank angle according to the above sensor signals , the signal category is signals other than the crankshaft position sensor and vehicle speed sensor, the speed is the signal of the engine sensor, and the crankshaft angle is the signal of the crankshaft position sensor.

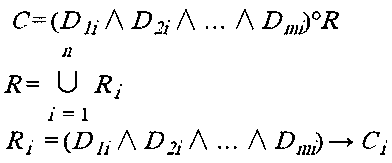

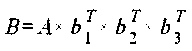

[0021] The Tucker decomposition is a high-order principal component analysis, which represents a tensor as a core (core) tensor multiplied by a matrix along each mode, assuming that the column vectors of the decomposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com