Job shop scheduling method based on discrete invasive weed algorithm

A technology for job workshops and scheduling methods, applied in computing, computing models, instruments, etc., can solve problems such as unstable operation results, long computing time, and poor accuracy, and achieve the effect of enhancing local search capabilities and deep search capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

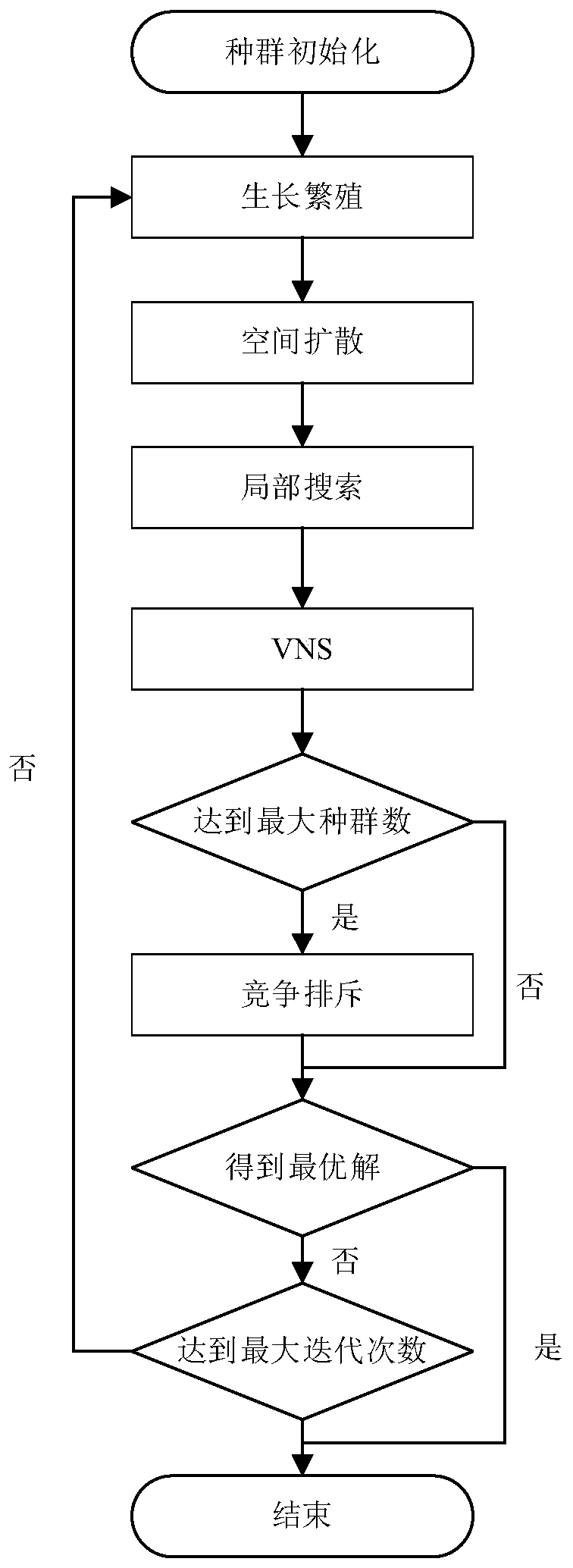

Method used

Image

Examples

Embodiment Construction

[0036] The application of the job shop scheduling method based on the discrete invasive weed algorithm:

[0037] There are M machines in the job shop scheduling problem, expressed as [1,2,..k,m,...,M], m and k are each a machine in the scheduling problem, and m≠k. Each machine can only process one process, and the process on each machine is different; the completion time of different workpieces on different machines is independent of each other, and it is guaranteed that all machines will not fail.

[0038] There are N workpieces to be processed in the job shop scheduling problem, expressed as: [1,2,..i,n,…,N], i and n are each a job in the scheduling problem, and n≠i. Each job can be processed in a different sequence, with independent completion times.

[0039] Suppose the completion time of job n on machine m is C n,m ;The processing time of workpiece n on machine m is l n,m ; When the goal of job shop scheduling is to minimize the maximum completion time, the objective f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com