Pesticide dry suspension agent suitable for flight control and preparation method and application thereof

A dry suspending agent and pesticide technology, applied in the field of pesticide dry suspending agent and its preparation, can solve the problems of poor anti-flying effect, low anti-drift and anti-volatile performance, and lack of anti-drift and anti-volatile performance of dry suspending agent. , to achieve the effect of high suspension rate, superior anti-volatile effect, and reduced volatility and drift performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Correspondingly, the embodiment of the present invention also provides a preparation method of the above pesticide dry suspension concentrate. The preparation method of the pesticide dry suspension of the embodiment of the present invention comprises the following steps:

[0045] Step 1: Weigh each component raw material respectively according to the components contained in the pesticide dry suspension concentrate of the embodiment of the present invention;

[0046] Step 2: Mix the raw materials of each component weighed in step 1 with water at a weight ratio of 3:7-1:1, stir evenly, and perform sand milling to obtain a suspension with a particle size of D50<2μm liquid;

[0047] Step 3: The suspension described in step 2 is spray-dried using a spray dryer under the condition that the inlet hot air temperature is 120-150°C and the outlet hot air temperature is 60-90°C to prepare the pesticide dry suspension .

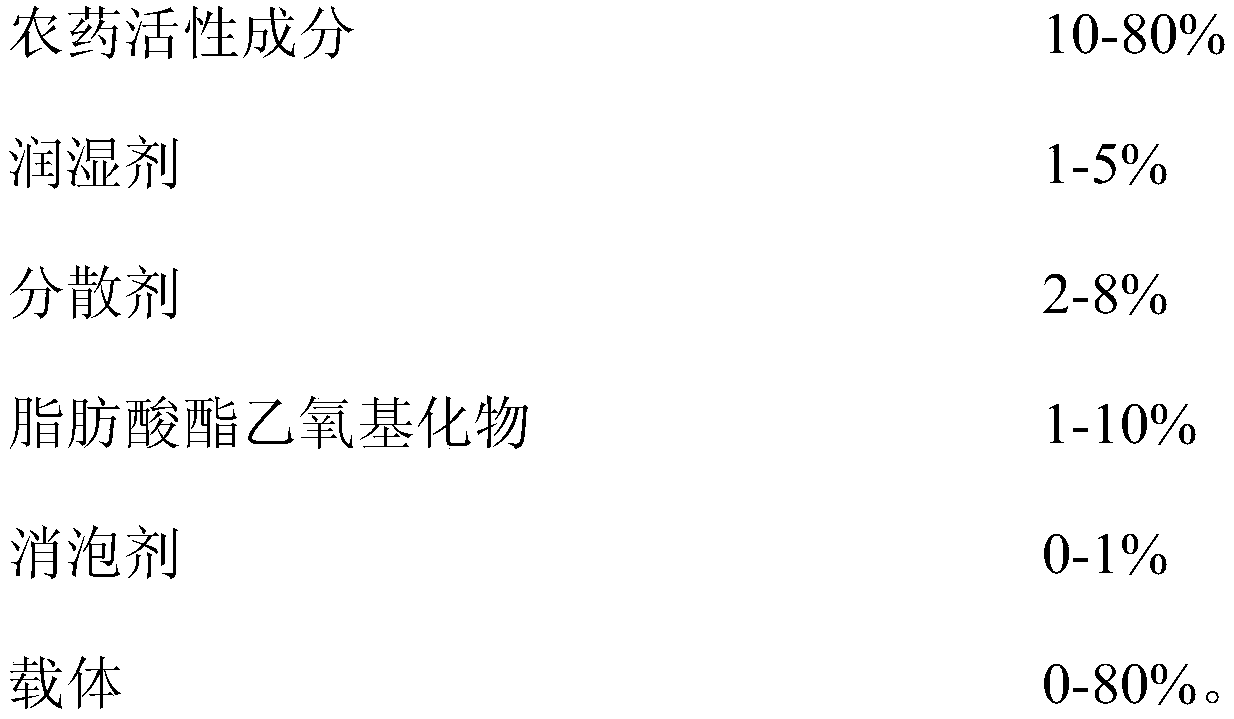

[0048] The weight ratio of each component raw material an...

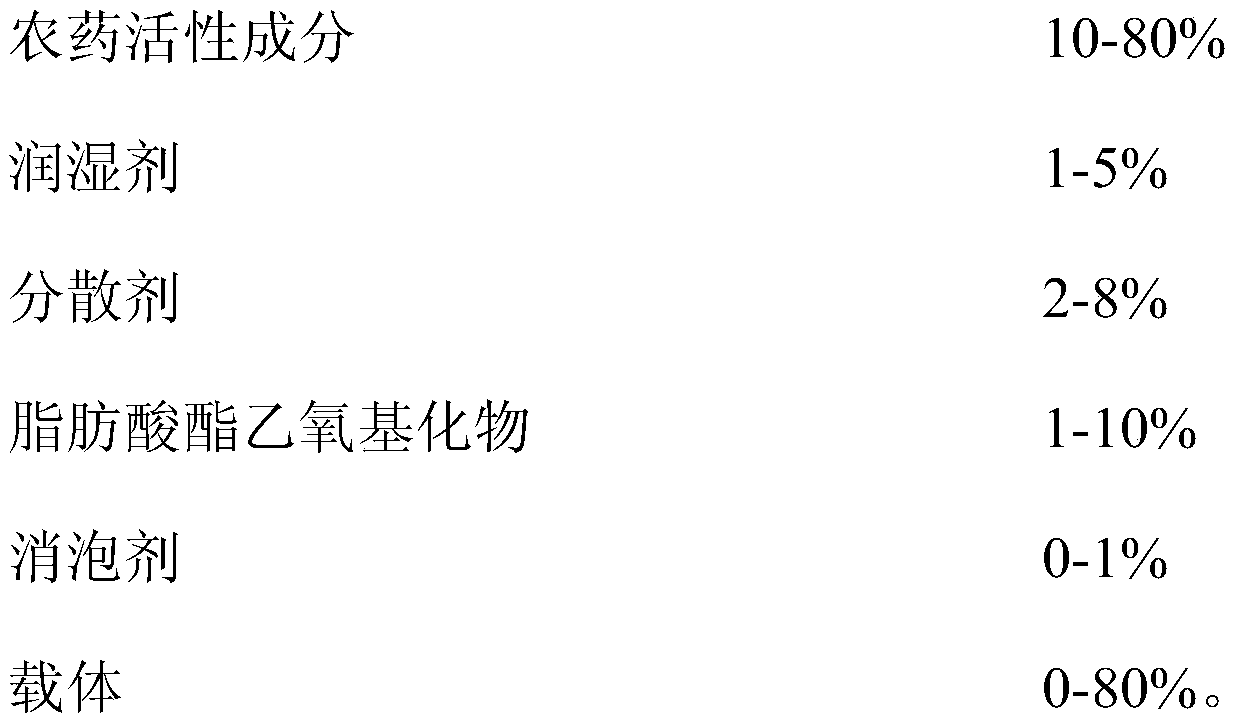

Embodiment 1

[0052]

[0053] Preparation method: Add the above-mentioned raw materials into 120g of water one by one, stir to form a uniform slurry, and put the slurry into a sand mill equipped with sanding beads for sand grinding to obtain water with an average particle size of D50<2μm Suspension sample: The above aqueous suspension is sprayed and granulated through a spray dryer with an inlet temperature of 140°C and an outlet temperature of 90°C.

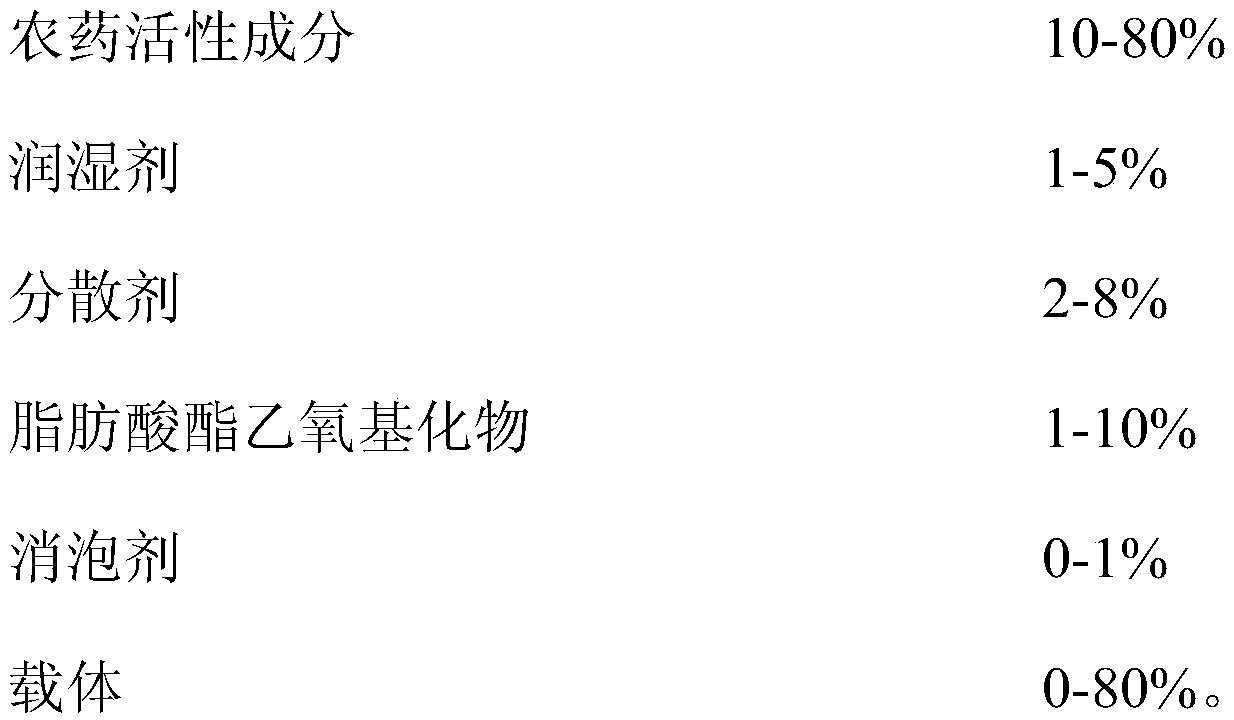

Embodiment 2

[0055]

[0056] Preparation method: Add the above-mentioned raw materials into 120g of water one by one, stir to form a uniform slurry, and put the slurry into a sand mill equipped with sanding beads for sand grinding to obtain water with an average particle size of D50<2μm Suspension sample: The above aqueous suspension is sprayed and granulated through a spray dryer with an inlet temperature of 120°C and an outlet temperature of 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com