Lead-acid storage battery gravity casting grid mold

A lead-acid battery and gravity casting technology, which is applied in the field of lead-acid battery gravity casting grid molds and lead-acid battery grid molds, can solve the problems of non-corrosion resistance of alloys, poor thermal conductivity, and coarse grains of castings, and achieve improved Casting molding rate, prolonging the life of the mold, and the effect of sufficient and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

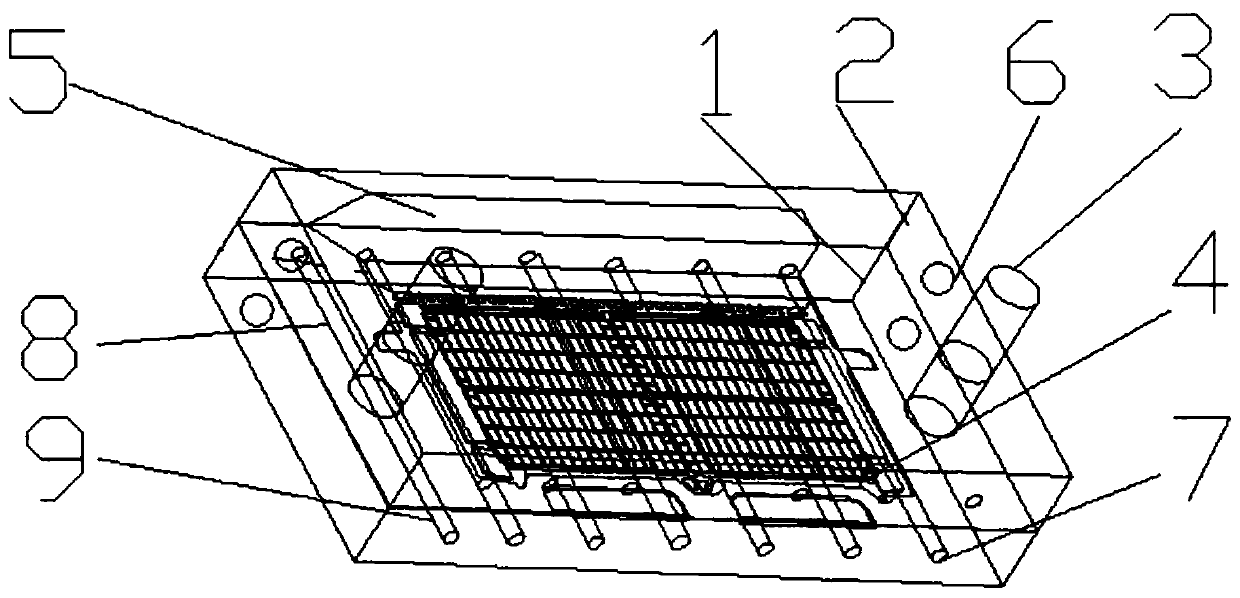

[0021] Embodiment 1, see figure 1 , a lead-acid battery gravity casting grid mold, including a fixed mold 1, a movable mold 2, a guide post 3, a grid cavity 4, a gate 5, a superconducting conduit hole 7, and a superconducting material 8; wherein: the guide post 3 One end is fixed on the top of the fixed mold 1, the movable mold 2 is provided with a through hole, the fixed mold 1 and the movable mold 2 are connected with the through hole through the guide post 3 to form a cooperating whole, the fixed mold 1 is provided with a lower mold cavity, and the movable mold 2 is provided with a There is an upper mold cavity, the fixed mold 1 and the movable mold 2 are fitted together so that the lower mold cavity and the upper mold cavity form a grid cavity 4, and the upper ends of the fixed mold 1 and the movable mold 2 are provided with a gate 5, and the gate 5 is connected with the plate The grid cavity 4 is connected, the lower ends of the fixed mold 1 and the movable mold 2 are pro...

Embodiment 2

[0024] This embodiment is based on embodiment 1, please refer to figure 1 , the superconducting material 8 is liquid or solid, which improves the practicability of the mould.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com