Hybrid power transmission and hybrid power driving system

A hybrid power and drive system technology, which is applied to the arrangement of multiple different prime movers of power plants, general power plants, and pneumatic power plants, etc., can solve problems such as user dissatisfaction, loud noise, and inability to work with electric motors, and achieve improved performance. The effect of power utilization and fuel consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

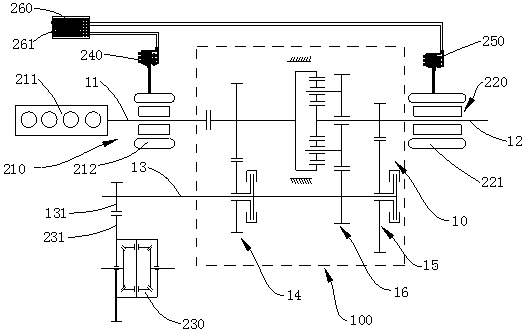

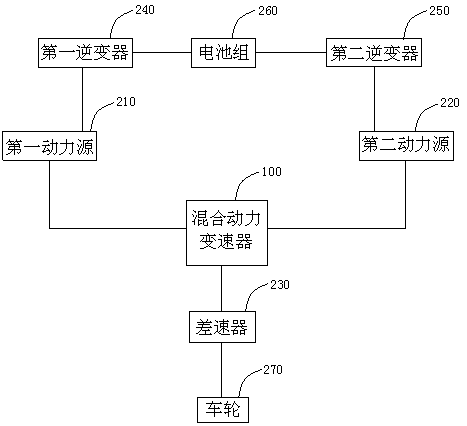

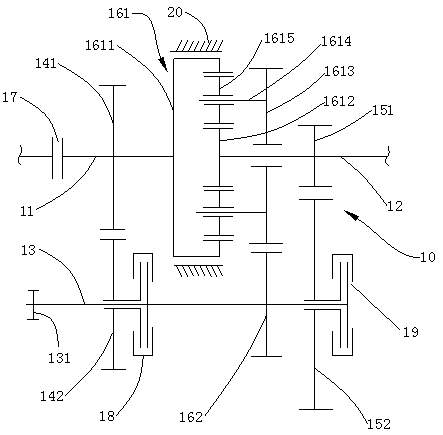

[0029] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution in this embodiment will be clearly and completely described below in conjunction with the accompanying drawings in this embodiment. Obviously, the described embodiment is the embodiment of the present invention. Some, but not all, embodiments. The components of the present embodiments generally described and shown in the figures herein may be arranged and designed in a variety of different configurations.

[0031] Accordingly, the following detailed description of the present embodiments provided in the accompanying drawings is not intended to limit the scope of the claimed invention, but merely represents selected embodiments of the invention. Based on the embodiments of the present invention, all other embodiments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com