Tower crane with monitoring system

A technology for monitoring systems and tower cranes, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of cumbersome device operation, inability to detect and alarm safely, and increase the workload of personnel, so as to reduce work burden and ensure Construction safety and comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

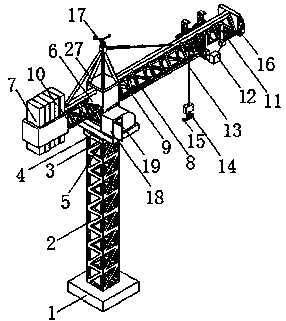

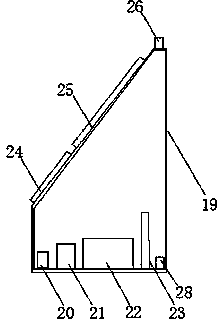

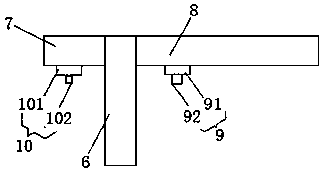

[0028]Tower crane structure, the tower crane base 1 provides bottom support, the upper end of the tower crane base 1 is provided with a standard section frame 2, the standard section frame 2 provides support, the upper end of the standard section frame 2 is provided with a top plate 3, the top plate 3 provides a place for placement, and the top plate The upper end of the slewing mechanism 4 is provided with a slewing mechanism 4 to realize the rotation of the tower crane. The upper end of the slewing mechanism 4 is provided with a stand 6 to provide a support connection. The left and right sides of the stand 6 are respectively provided with a balance arm 7 and a lifting arm 8 , the balance arm 7 ensures the stability of the hoisting, the jib 8 is used as a support during hoisting, the upper end of the jib 8 is slidably connected with a sliding trolley 11, which is convenient for adjusting the hoisting position, and the inside of the sliding trolley 11 is equipped with a hoisting...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that it also includes a torque sensor 5, which can monitor the torque information of the rotary mechanism 4 in real time. The output shaft is fixedly connected to the rotating shaft of the slewing mechanism 4 through a shaft coupling, and the torque sensor 5 is electrically connected to the PLC controller 22 .

[0034] Example three

[0035] The difference between this embodiment and Embodiment 1 is that it also includes a tie rod brace 27 and a wind speed sensor 17, the tie rod brace 27 ensures the stability of the system during hoisting, the wind speed sensor 17 can monitor the wind speed in real time, and the tie rod brace 27 is arranged on The upper end of the stand 6, the front tie rod of the tie rod brace 27 is fixedly connected with the middle part of the upper end of the boom 8, the rear tie rod of the tie rod brace 27 is fixedly connected with the upper middle part of the balance arm 7, and the wind spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com