Preparation method for monodisperse cobaltous sulfide hollow sandwich microsphere

A cobalt sulfide, monodisperse technology, applied in cobalt sulfide, chemical instruments and methods, inorganic chemistry, etc., to achieve excellent electrochemical performance and electromagnetic performance, high yield, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

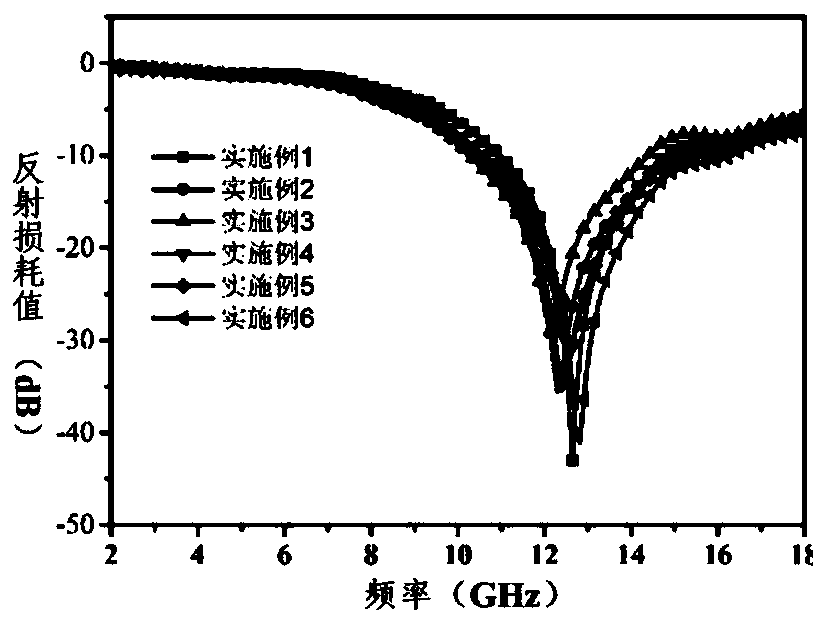

Examples

Embodiment 1

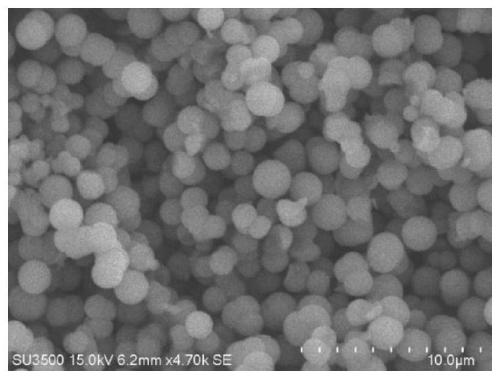

[0026] Step 1: Weigh 0.004mol of cobalt nitrate and 1.0g of PVP and dissolve them in 80ml of mixed reaction solvent with ultrasonic stirring at room temperature. The volume ratio of glycerol and isopropanol in the mixed reaction solvent is 1:3. After the metal salt and surfactant are completely dissolved, pour into a hydrothermal synthesis kettle with a volume of 100ml and react at 160°C for 12 hours, cool naturally to room temperature, wash with water, wash with alcohol, centrifuge, and dry to obtain the solid microsphere metal alkoxide precursor;

[0027] Step 2: Ultrasonically disperse 0.1g of the solid microsphere metal alkoxide precursor at room temperature into 20ml of absolute ethanol solution containing 0.3g of thioacetamide, inject into a hydrothermal synthesis kettle with a volume of 25ml, and react for 8h at 180°C, and cool naturally to room temperature, washed with water, washed with alcohol, centrifuged and dried to obtain the metal sulfide with hollow sandwich mic...

Embodiment 2

[0030] Step 1: Weigh 0.006 mol of cobalt nitrate and 0.5 g of CTAB and dissolve them in 80 ml of mixed reaction solvent with ultrasonic stirring at room temperature. The volume ratio of glycerol and isopropanol in the mixed reaction solvent is 1:5. After the metal salt and surfactant are completely dissolved, inject into a hydrothermal synthesis kettle with a volume of 100ml at 200°C for 8 hours, cool naturally to room temperature, wash with water, wash with alcohol, centrifuge, and dry to obtain the solid microsphere metal alkoxide precursor;

[0031] Step 2: Ultrasonically disperse 0.1g of solid microsphere metal alkoxide precursor into 20ml of absolute ethanol solution containing 0.1g of thioacetamide at room temperature, inject into a hydrothermal synthesis kettle with a volume of 25ml, and react for 12h at 140°C for vulcanization, and cool naturally to room temperature, washed with water, washed with alcohol, centrifuged, and dried to obtain a metal sulfide with a hollow s...

Embodiment 3

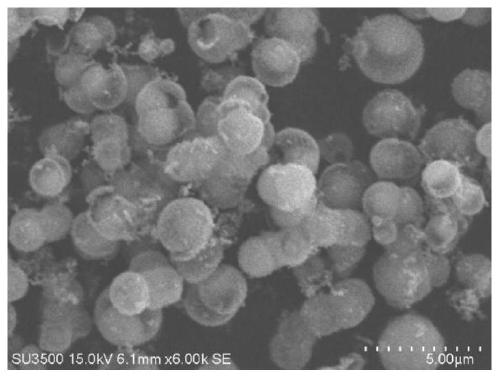

[0034] Step 1: Weigh 0.008 mol of cobalt nitrate and 1.0 g of SDBS and dissolve them in 80 ml of mixed reaction solvent with ultrasonic stirring at room temperature. The volume ratio of glycerol and isopropanol in the mixed reaction solvent is 1:7. After the metal salt and surfactant are completely dissolved, inject into a hydrothermal synthesis kettle with a volume of 100ml and react at 180°C for 8 hours, cool naturally to room temperature, wash with water, wash with alcohol, centrifuge, and dry to obtain a solid microsphere metal alkoxide precursor;

[0035] Step 2: Ultrasonically disperse 0.1g of solid microsphere metal alkoxide precursor in 20ml of anhydrous ethanol solution containing 0.2g of sodium sulfide at room temperature, inject into a hydrothermal synthesis kettle with a volume of 25ml for sulfidation reaction at 160°C for 10h, and cool naturally to room temperature , washed with water, washed with alcohol, centrifuged and dried to obtain the hollow sandwich microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap