Micro-expansion waterproof mortar and preparation method thereof

A waterproof mortar and micro-expansion technology, applied in the field of building materials, can solve problems such as difficult to meet, requirements, etc., and achieve the effect of improving waterproofing, meeting engineering needs, and improving engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

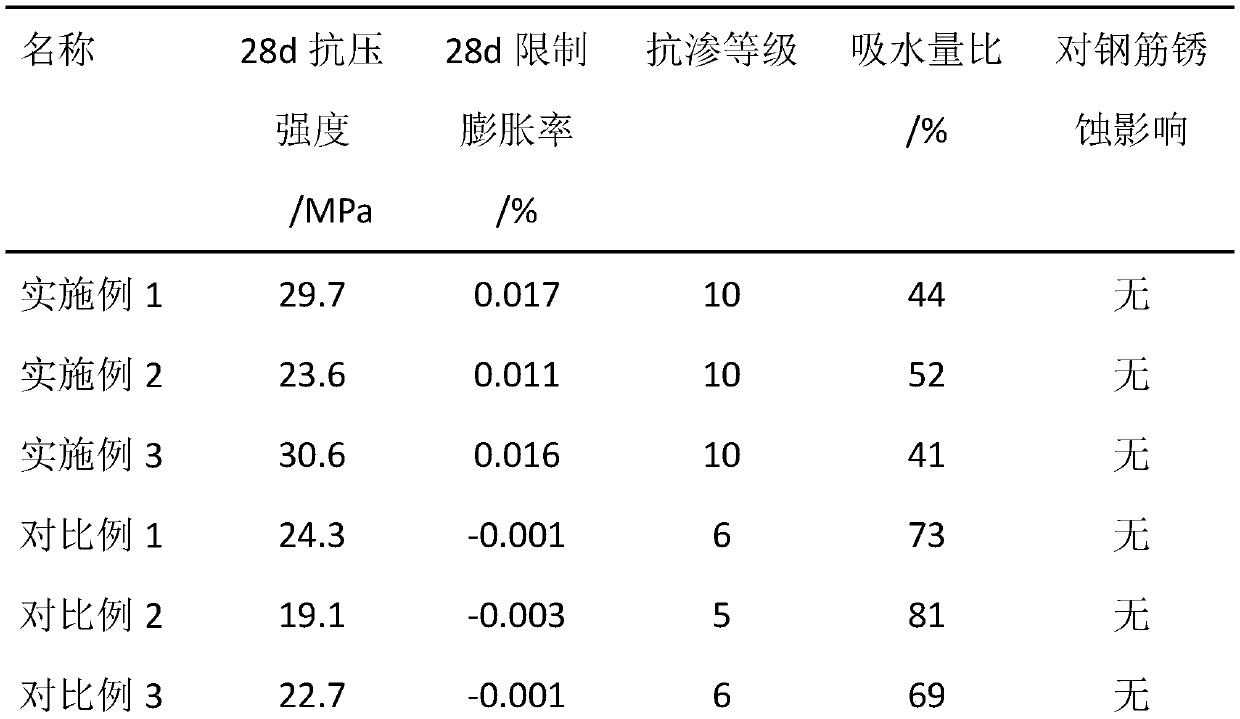

Examples

Embodiment 1

[0014] Take 75 parts of cement, 25 parts of fly ash, and 300 parts of sand according to the weight percentage of raw materials, stir evenly, then add 75 parts of water, stir until viscous, finally add 0.5 parts of polypropylene fiber, and 1.7 parts of redispersible latex powder, 0.4 part of cellulose ether, 0.1 part of UEA expansion agent, 0.05 part of water reducer, and 0.02 part of nano calcium carbonate were stirred and mixed.

Embodiment 2

[0016] Take 95 parts of cement, 5 parts of fly ash, and 300 parts of sand according to the weight percentage of raw materials, stir evenly, then add 100 parts of water, stir until viscous, finally add 2.3 parts of polypropylene fiber, and 0.6 part of redispersible latex powder. 0.9 parts of cellulose ether, 2.7 parts of UEA expansion agent, 3 parts of water reducing agent, and 2 parts of nano calcium carbonate were stirred and mixed.

Embodiment 3

[0018] Take 80 parts of cement, 20 parts of fly ash, and 300 parts of sand according to the weight percentage of raw materials, stir evenly, then add 80 parts of water, stir until viscous, finally add 1.5 parts of polypropylene fiber, and 1 part of redispersible latex powder. 0.5 part of cellulose ether, 0.8 part of UEA expansion agent, 0.9 part of water reducer, and 0.6 part of nano calcium carbonate were stirred and mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com