Deep hole ultrasonic vibration impact strengthening device and method

An ultrasonic vibration and impact strengthening technology, which is applied in the field of deep hole ultrasonic vibration impact strengthening, can solve the problems of low strengthening efficiency and poor effect, and achieve the effect of small size, convenient hand-held and mobile, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

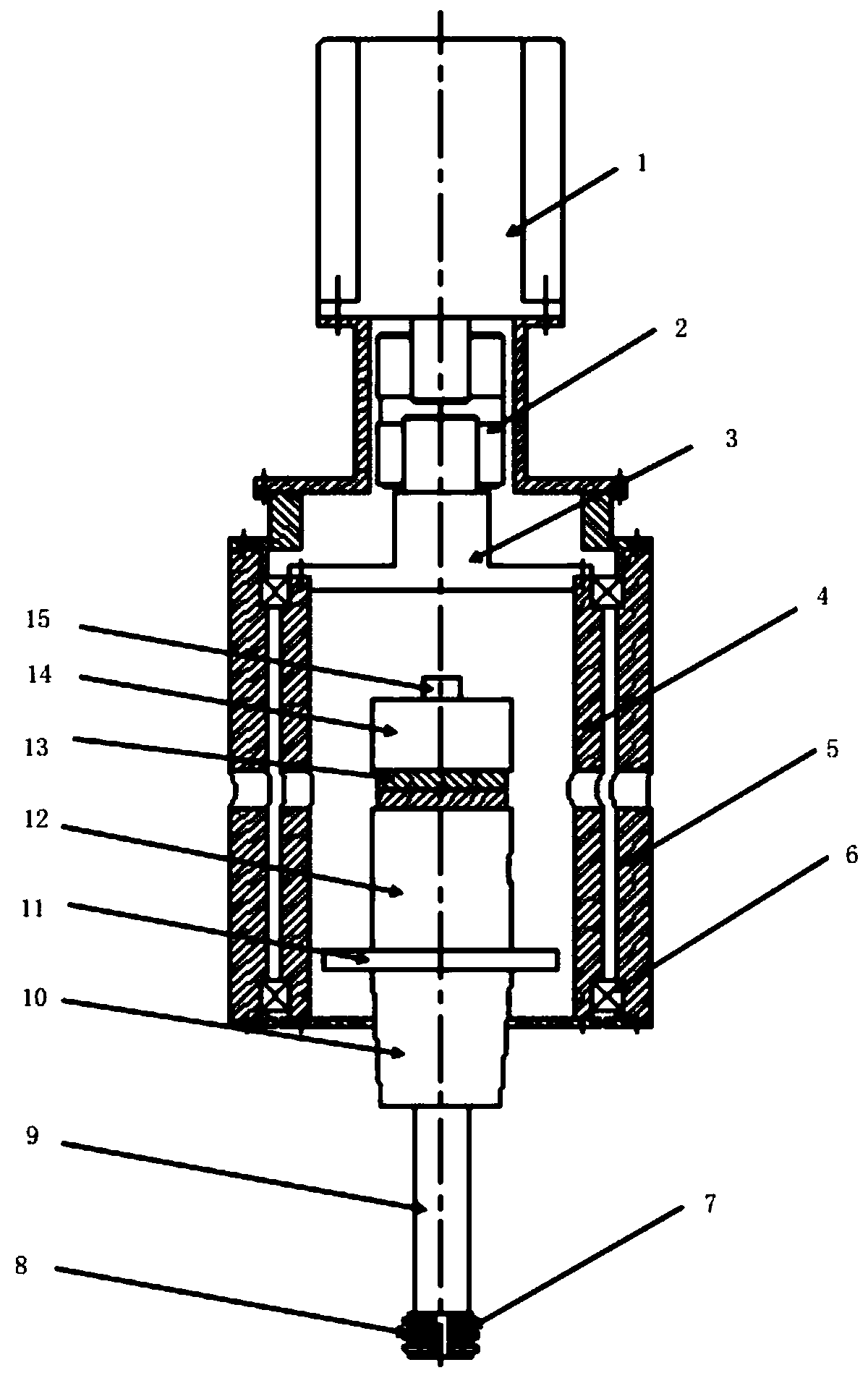

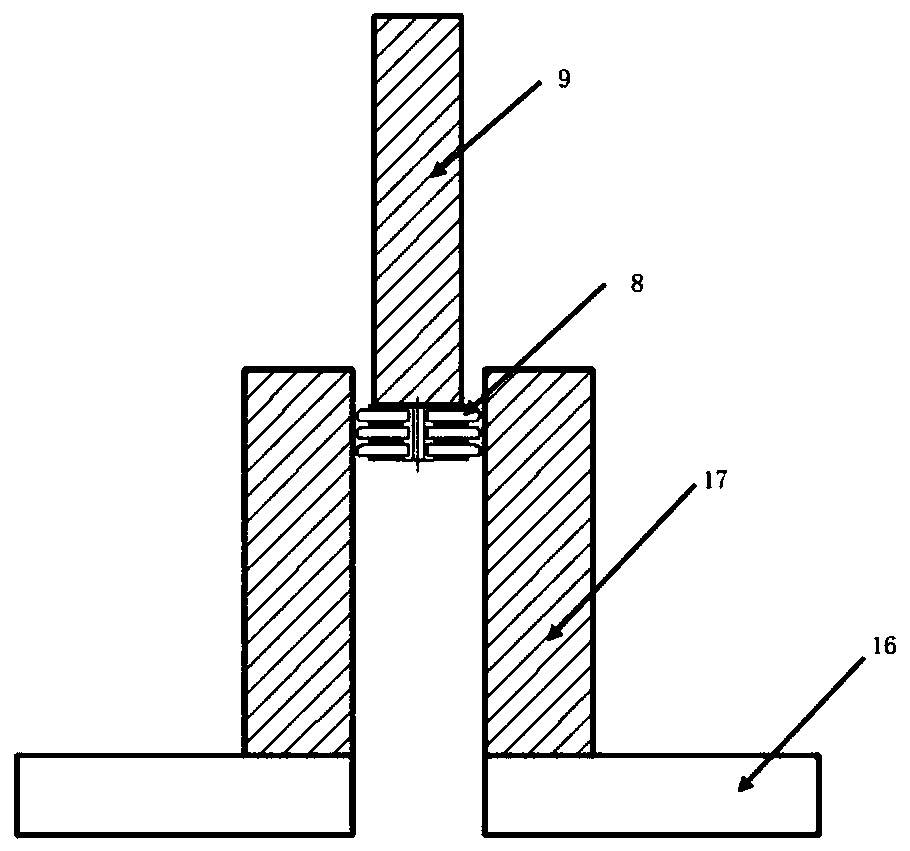

[0028] Such as figure 1 As shown, an ultrasonic vibration impact strengthening device includes an ultrasonic bending vibration system, a rotation assist system and an impact device.

[0029] The ultrasonic bending vibration system includes: an ultrasonic generator, a bending vibration transducer and an ultrasonic horn. The bending vibration transducer includes a screw rod 15 , a front cover plate 14 , a piezoelectric ceramic sheet 13 , a rear cover plate 12 and a bending vibration circular plate 11 . Among them, the screw 15, the front cover plate 14, the piezoelectric ceramic sheet 13 and the rear cover plate 12 form a long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com