An assembled prefabricated wall panel, its manufacturing method and its mold

A prefabricated wall panel, prefabricated technology, applied in the direction of molds, building materials, etc., can solve the problems of concrete performance impact, increased cost and energy consumption, poor integrity of components, etc., and achieves low production cost, light weight, and good thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

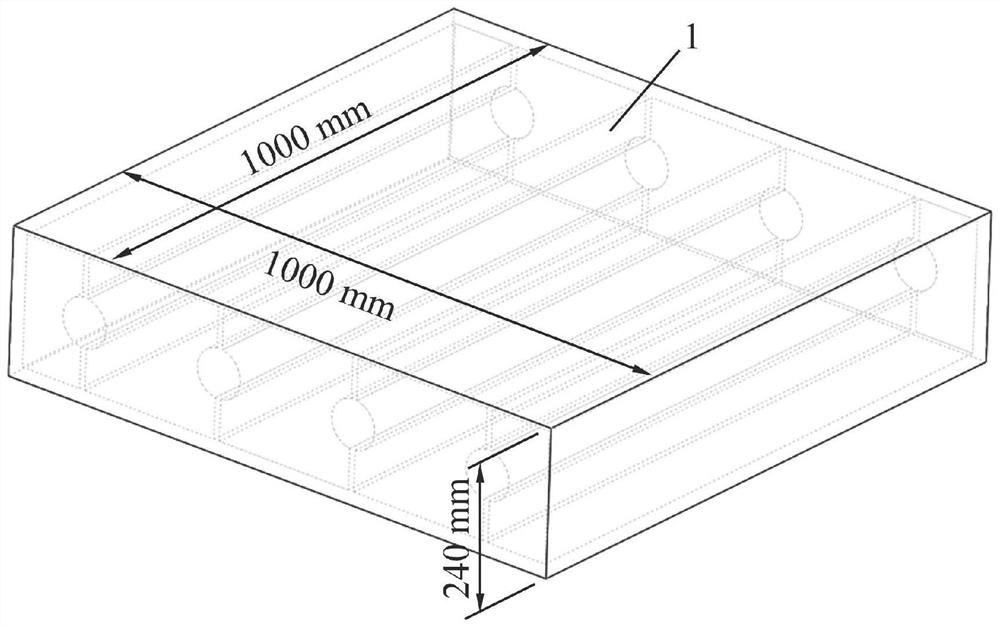

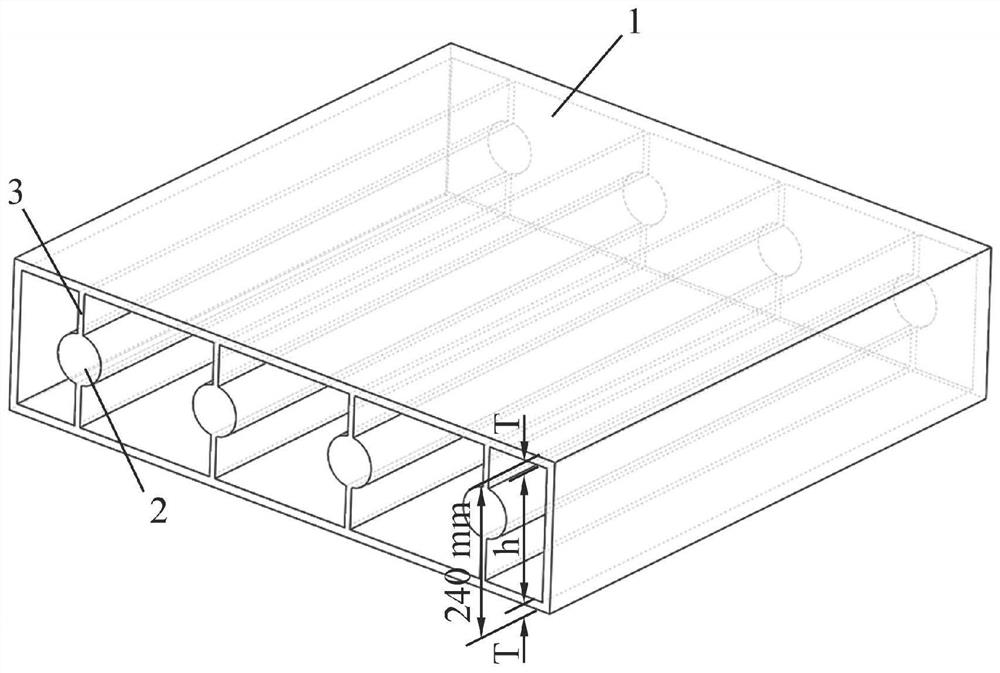

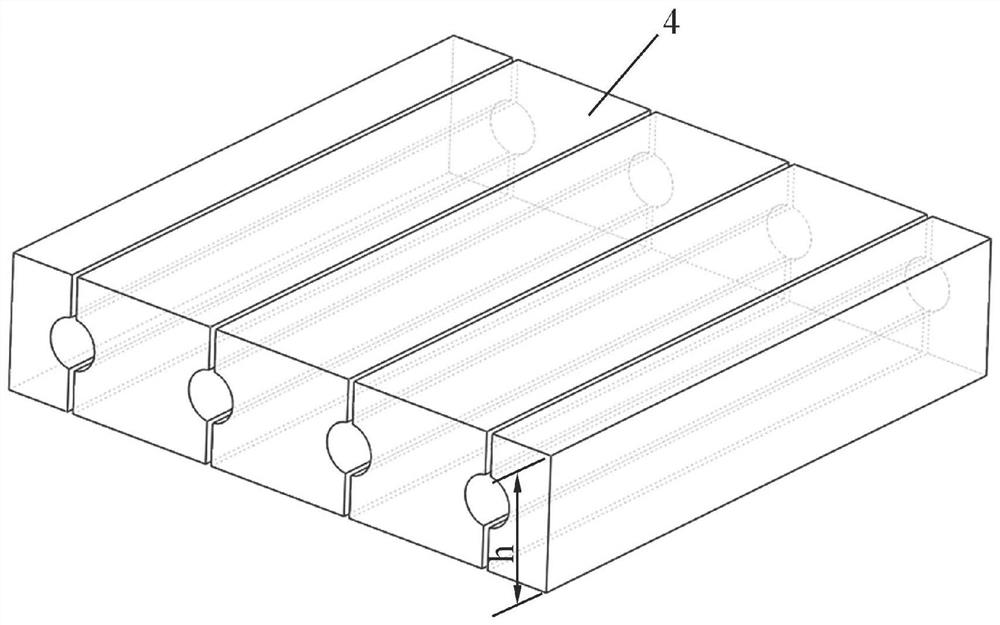

[0043] figure 1 It is the physical model diagram of the vertical column beetle board; figure 2 It is a schematic diagram of the internal structure of the vertical column beetle board after removing the upper frame and the core straw board; image 3 It is a schematic diagram of the structure of the core straw board.

[0044] refer to Figure 1-3As shown, the vertical column beetle board is a sandwich panel characterized by vertical columns and honeycomb wall structure. It mainly consists of four parts, which are concrete outer frame 1, vertical column 2, honeycomb wall 3 and core straw board 4. The concrete outer frame constitutes the periphery of the vertical column beetle board, and the vertical column 2, the honeycomb wall 3 and the core straw board 4 jointly form the core layer of the vertical column beetle board.

[0045] The structural parameters of the above components are: number of columns: N; vertical column radius: R; honeycomb wall thickness: t; concrete frame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com