Coupling with quick removable sleeve cover

A quick-release, coupling technology, used in couplings, rigid shaft couplings, mechanical equipment, etc., can solve the difficulty in the replacement and disassembly process of mechanical shaft seals such as pump shafts, and the difficulty of coupling with bare shafts. The problems of inconvenient disassembly, assembly, and maintenance are solved by knocking and knocking, so as to achieve the effect of improving the current energy consumption of the equipment, increasing the strength, and improving the installation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

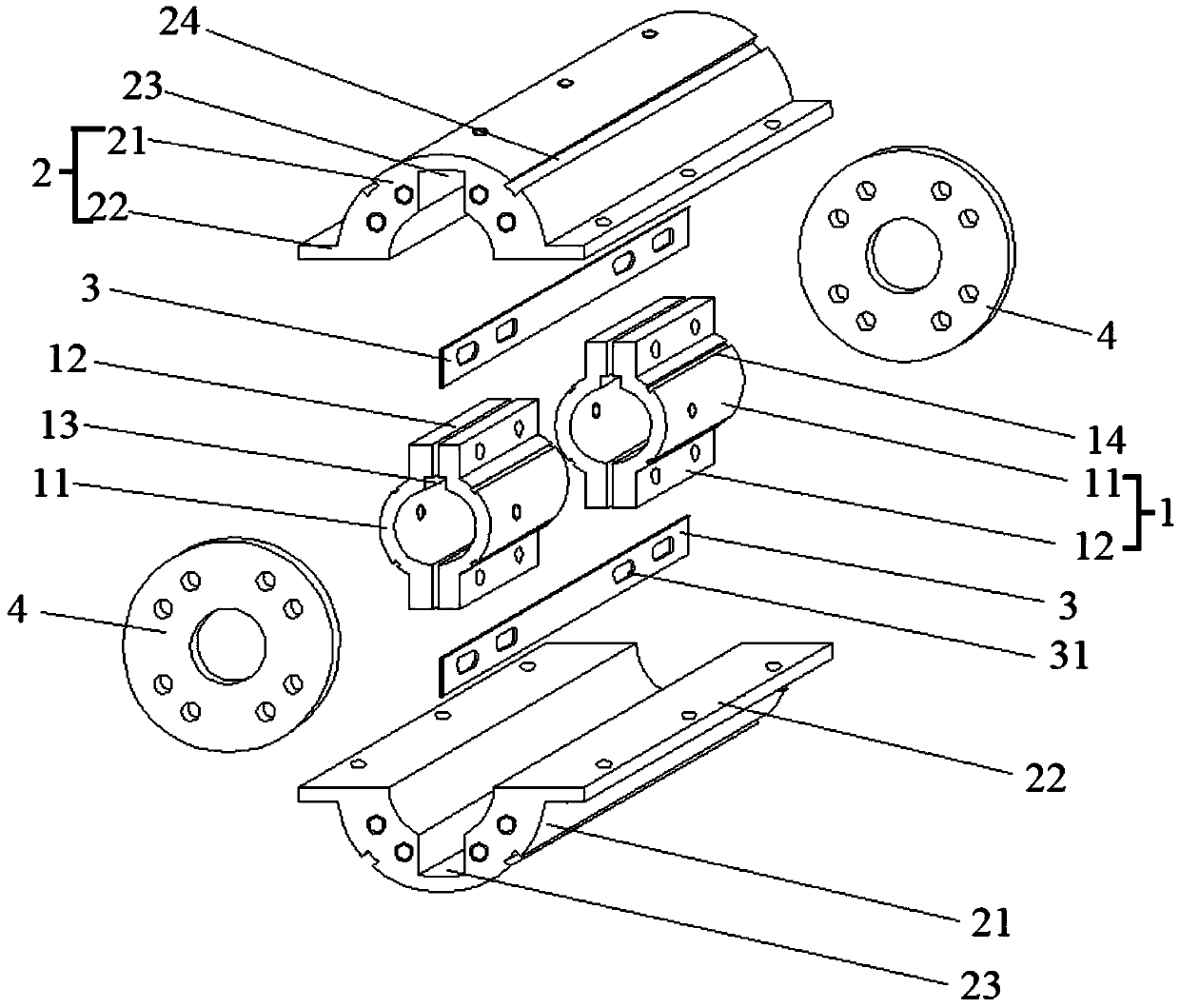

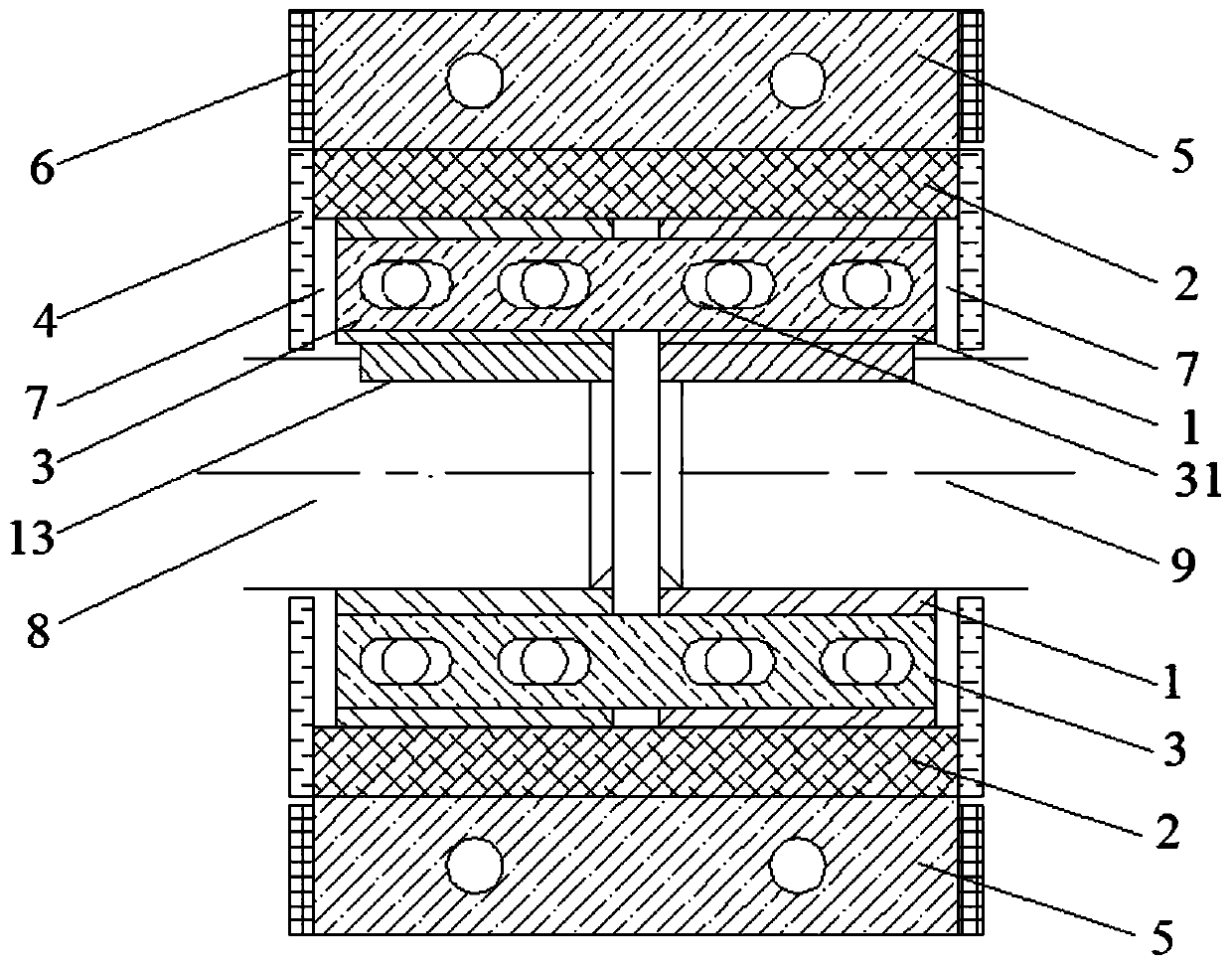

[0034] Specific embodiment one (the shaft coupling that does not contain outer cover):

[0035] A cover quick-release shaft coupling includes two sets of shaft sleeves 1 and a set of shaft covers 2, wherein the two sets of shaft sleeves 1 are arranged at opposite intervals along the axial direction, and a set of shaft covers 2 connects the two sets of shaft sleeves 1 in the Together. In order to ensure the torque load strength, the two sets of shaft sleeves 1 are made of metal materials, and the metal material is preferably cast iron; in order to reduce the weight of the entire coupling and reduce the weight of the shaft cover, the shaft cover 2 can be made of high-strength It is made of plastic materials, such as high-strength composite polymer, which can be made of nylon alloy, PC alloy and other materials. The shaft cover 2 can also be made of metal alloy with high strength and light weight.

[0036] One of the two sets of sleeves is sleeved on the driving transmission sha...

specific Embodiment 2

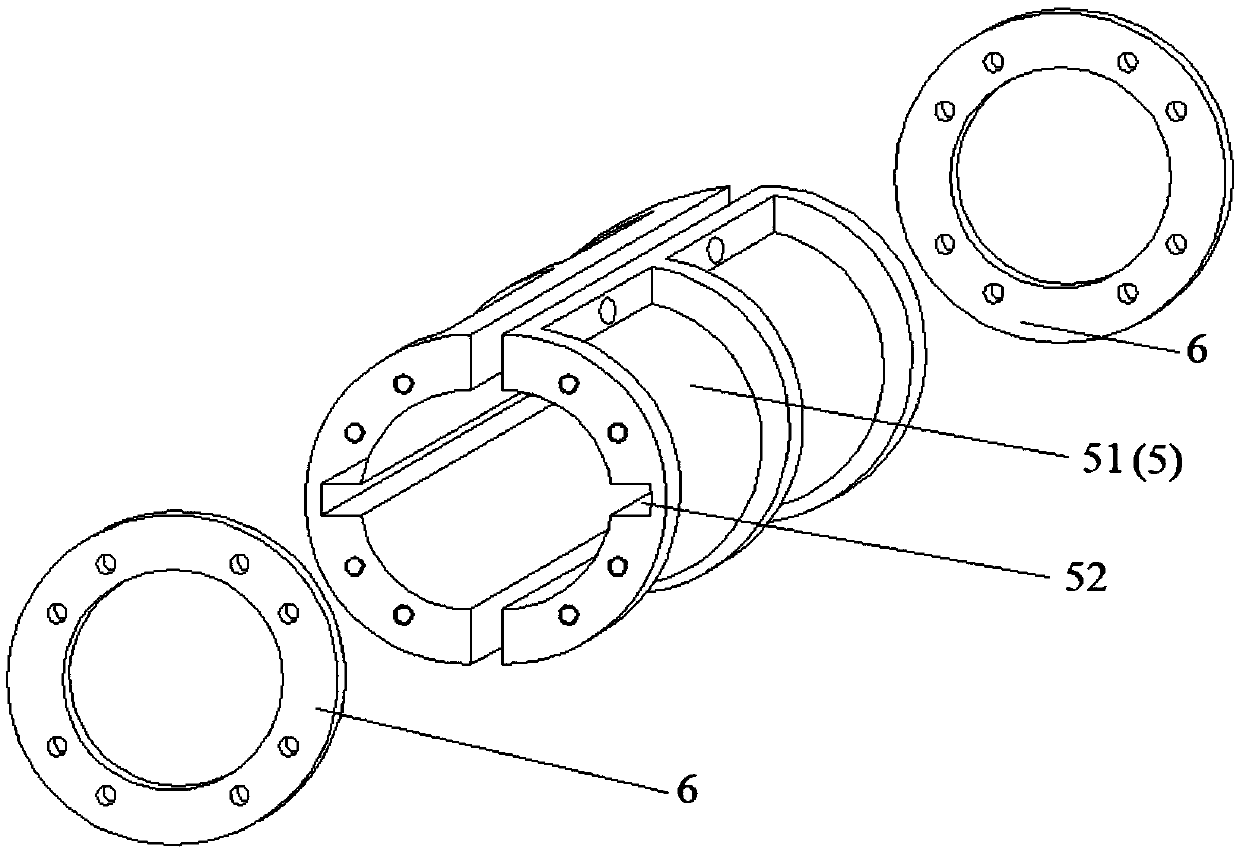

[0042] Specific embodiment two (contain the shaft coupling of outer cover):

[0043] A cover quick-release shaft coupling includes two sets of shaft sleeves 1, a set of shaft covers 2 and a set of outer casing covers 5, wherein two sets of shaft sleeves 1 are arranged at intervals in the axial direction, and a set of shaft covers 2 connects the two The sets of shaft sleeves 1 are connected together, and a set of outer casing covers 5 are positioned and sleeved on the outside of the shaft covers. In order to ensure the torque load strength, the two sets of shaft sleeves 1 are made of metal materials, and the metal material is preferably cast iron; in order to reduce the weight of the entire coupling and reduce the weight of the shaft cover, the shaft cover 2 can be made of a certain strength It is made of plastic material or composite rubber material with a certain strength. The plastic material can be a composite polymer with a certain strength. Specifically, materials such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com