Multi-mode curved surface phased array ultrasonic tomography device

A technology of ultrasonic tomography and phased array, which is applied in measuring devices, analyzing solids using sound waves/ultrasonic waves/infrasonic waves, and using sound waves/ultrasonic waves/infrasonic waves for material analysis. It can solve monitoring and distribution parameter estimation, and a single test mode , ultrasonic tomography and other problems, to achieve the effect of strong anti-electromagnetic interference, rich modulation information, and broaden the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The multi-mode curved phased array ultrasonic tomography device of the present invention will be described with reference to the accompanying drawings and embodiments, and is intended to be described as an embodiment of the present invention, not the only form that can be manufactured or utilized, and the same function can be achieved for other The embodiments of the invention should also be included within the scope of the present invention.

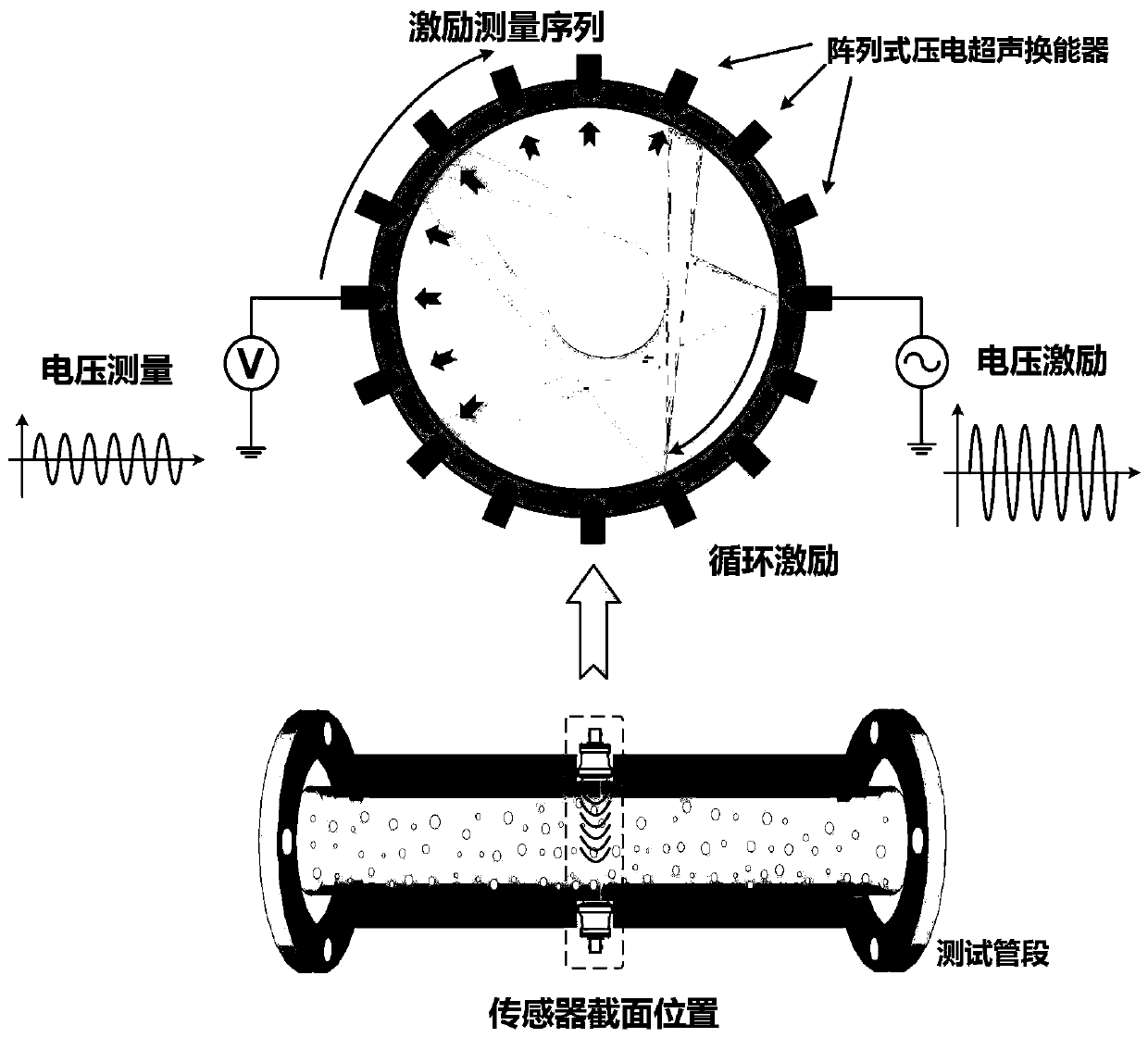

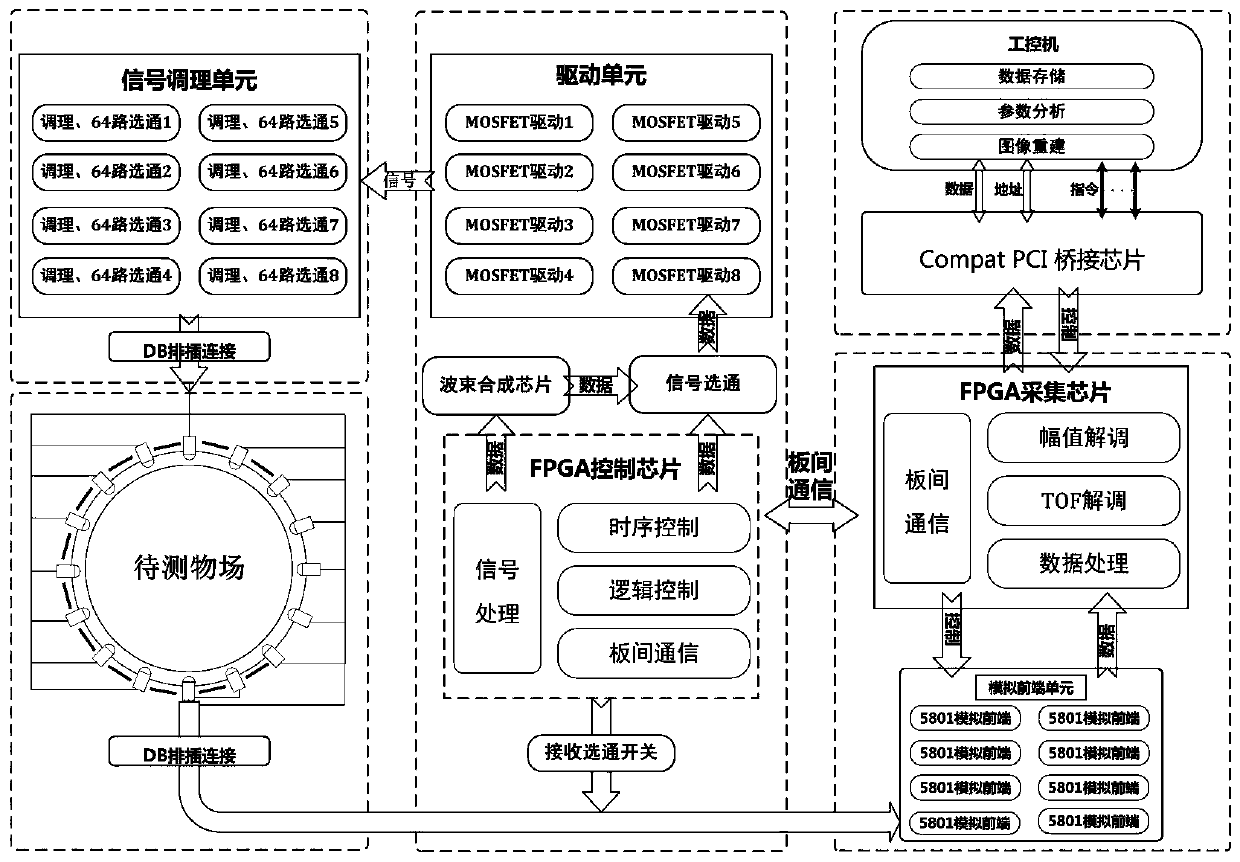

[0022] figure 1 It is the basic test principle diagram of the device of the present invention, including the test tube section, a set of ultrasonic transducer arrays with 64 probes of single section. The probe array is composed of 64 independent ultrasonic transducers, which are evenly distributed along the outer wall of the pipe in the same pipe section, and the angle between adjacent sensors is the same. The excitation signal of each probe is individually modulated, and the sound pressure response of each probe is collected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com